2. Lubricate the crankshaft journals with engine oil and lay the shaft on the bed of bearings.

3. Insert the non-grooved shells into the main bearing caps and lubricate them with engine oil.

4. On all engines except the 1.0L engine, lubricate the thrust washers with engine oil and insert them into the center main bearing cap (grooves to the cheeks of the crankshaft).

5. Install the main bearing caps according to the marks on them (Bearing numbers stamped on side of caps). The first bearing is considered to be on the drive side of the camshaft.

6. Tighten the bolts securing the main bearing caps for engines 1.0 l, 37 kW and 1.4 l, 50 kW to a torque of 75 Nm, for a diesel engine 1.9 l, 74 kW - 65 Nm, then tighten another 90°. Tighten the middle cover bolts first (third), then adjacent to it (second and fourth) and last but not least, extreme (first and fifth). Turn the crankshaft, it should rotate easily, without jamming.

7. Install the rear oil seal holder. For engines 1.0 l, 37 kW and 1.4 l, 50 kW, pre-lubricate the sealing lip with engine oil, and apply Loctite 574 sealant to the holder and the threads of the holder fastening bolts. Tighten the bolts with a torque of 8 Nm.

8. Install the flywheel, taking into account that on all engines, except for engines 1.0 l, 37 kW and 1.4 l, 50 kW, it is installed in only one position due to the asymmetrical arrangement of the holes. Replace the flywheel mounting bolts with new ones and tighten them to 60 Nm, then tighten by 90°.

9. For engines of 1.0 l, 37 kW and 1.4 l, 50 kW, lubricate the camshaft journals and cams with engine oil and install the shaft in the cylinder block. Install lock plate 9 (see fig. Camshaft for 1.0L, 37kW and 1.4L, 50kW engines) and tighten the bolts 10 of its fastening to a torque of 5 Nm.

10. For 1.0l, 37kW and 1.4l, 50kW engines, install the cylinder liners so that they do not touch each other. Check sleeve protrusion (see subsection 2.13.2).

11. Slide the piston onto the connecting rod so that the arrow on the piston crown and projection B (see fig. Details of the connecting rod and piston group of the engine with a volume of 1.4 l, 55 and 74 kW and fig. Details of the connecting rod and piston group of a diesel engine 1.9 l, 74 kW) on the bottom head of the connecting rod were directed in one direction. For engines 1.0 l, 37 kW and 1.4 l, 50 kW, the arrow is directed towards the camshaft and is located on the side of hole B (see fig. Details of the connecting rod and piston group of engines 1.0 l, 37 kW and 1.4 l, 50 kW) in the connecting rod to lubricate the piston pin. In addition, the pistons must be of the same weight group by mass (group designation «+» or «-» knocked out on the bottom of the piston). Lubricate the piston pin with engine oil and insert it into the piston with the connecting rod. Install the piston pin circlips into the grooves on the piston. If the pin is too tight in the piston holes, heat the piston to 60°C.

12. Install the rings on the pistons. This is best done with a piston ring remover. For gasoline engines, the oil scraper ring is composite, so it must be installed manually, carefully spreading the ring locks. The rings are installed with the inscription TOP up, to the bottom of the piston. The rings should rotate freely in the piston grooves, and their locks should be located at an angle of 120°to each other.

13. Insert the bearing shells into the lower connecting rod heads and connecting rod caps. Diesel engines have a black stripe on the running surface near the edge on the top bearings. For engines of 1.4 l, 50 kW, the fixing protrusions of the liners must enter the grooves of the connecting rod and the cover, for other engines, the liners must be installed so that the connecting rod head and the cover protrude in width on both sides of the liner by the same distance. Lubricate the liners with engine oil.

14. Squeeze the piston rings with a mandrel and carefully insert the connecting rod with the piston into the cylinder, while the arrow on the piston crown must be directed towards the camshaft drive (for engines 1.0 l, 37 kW and 1.4 l, 50 kW, the arrow is directed towards the camshaft). The ring compression mandrel must be pressed against the cylinder block. Hitting the bottom of the piston with a hammer handle, move it from the mandrel into the cylinder.

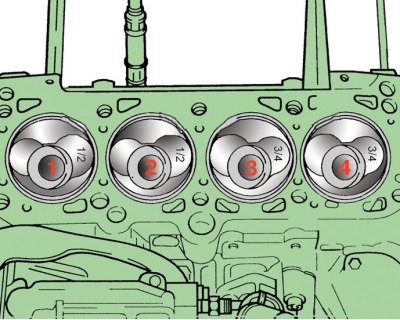

15. For a 1.9 liter, 74 kW diesel engine, the pistons are installed in the first and second cylinders with a recess for the intake valve (bigger size), towards the back of the engine (flywheel), and in the third and fourth cylinders - to the front (camshaft drive), as it shown on the picture.

16. Install the connecting rod cap with bushing onto the connecting rod, with the cylinder numbers stamped on the cap and connecting rod on the same side.

17. Wrap the connecting rod bolts, for a 1.4 l, 50 kW engine - the nuts of the connecting rod bolts. On all engines except 1.4L, 50kW, replace the connecting rod bolts with new ones, lubricating with engine oil their threads and the surface of the head in contact with the cover before tightening. Tighten the bolts (for the engine 1.4 l, 50 kW - nuts of the connecting rod bolts) on engines 1.0 l, 37 kW and 1.4 l, 55 and 74 kW with a torque of 20 Nm, then tighten another 90°; on engines 1.4 l, 50 kW - 40 Nm; on diesel engines 1.9 l, 74 kW - 30 Nm, then tighten another 90°.

18. For 1.0L, 37kW and 1.4L, 50kW engines, install timing gears (see subsection 2.5) and gear cover.

19. Install the oil pump (see subsection 3.3).

20. Apply sealant to the flange of the oil crankcase, install the crankcase and tighten the bolts of its fastening.

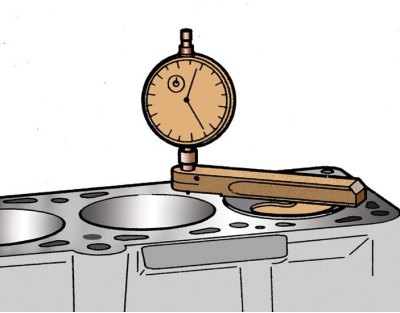

21. For a diesel engine, select the head gasket for thickness. To do this, measure the protrusion of the pistons at TDC above the upper plane of the block, as shown in the figure. Depending on the protrusion of the pistons, select a new gasket, while taking into account the largest protrusion.

22. Spare parts are supplied with gaskets of various thicknesses, which are marked with the number of holes 3 (see fig. Diesel cylinder head gasket marking). A gasket 0.91–1.0 mm thick has one hole, 1.01–1.10 mm thick has two holes, and 1.11–1.20 mm thick has three holes.

23. Install the cylinder head (see subsection 2.7) and attachments for the engine.