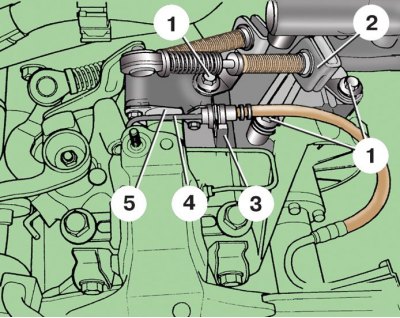

02T transmission cable bracket fasteners

1 – a bolt of fastening of an arm; 2 - bracket; 3 - tube holder; 4 – a tube of a hydraulic drive of coupling; 5 - working cylinder

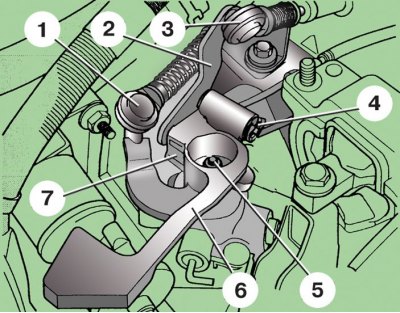

Removing the drive levers to the gearbox

1 – a tip of a cable of inclusion of transfer; 2 - gear selection lever; 3 – a tip of a cable of a choice of transfers; 4 - retaining ring; 5 - nut; 6 – the lever of inclusion of transfers; 7 - slider

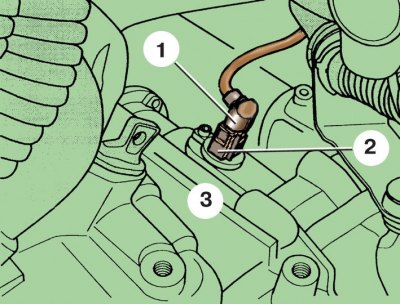

Location of the speedometer drive speed sensor on the gearbox type 02T

1 - connecting block; 2 – speedometer drive speed sensor; 3 - gearbox

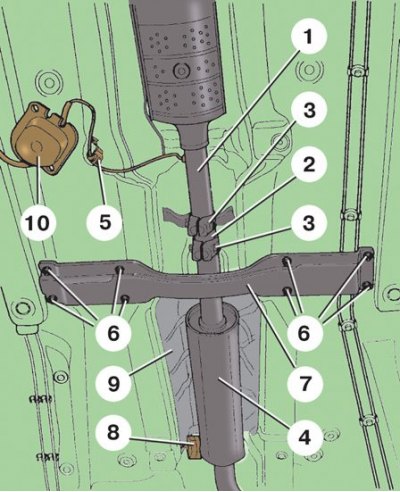

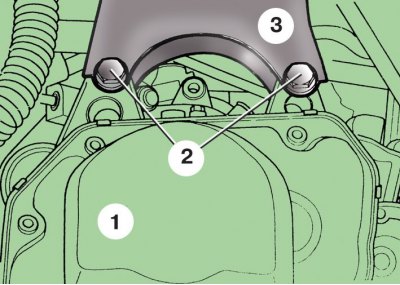

Silencer front pipe coupling on models with 02T gearbox

1 – a reception pipe of the muffler; 2 - connecting sleeve; 3 - coupling bolt; 4 - resonator; 5 - holder; 6 - nut; 7 - cross member; 8 – resonator mounting pad; 9 - heat-insulating screen; 10 – a protective casing of a block of the oxygen gauge (lambda probe)

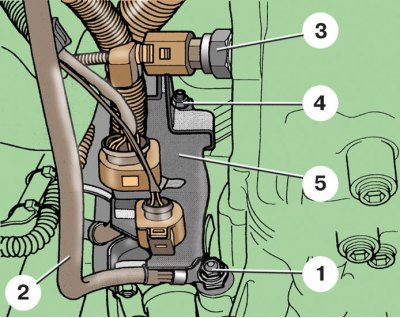

Fastening «mass» wires to gearbox type 02T

1 - bolt; 2- «mass» the wire; 3 - reverse light switch; 4 - nut; 5 - bracket

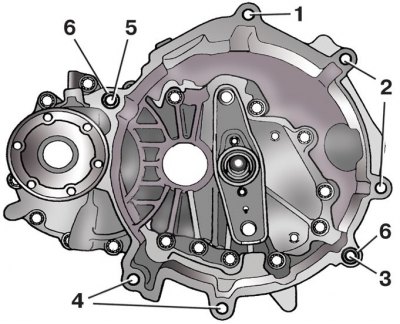

Arrangement of attachment points of gearbox type 02T to the engine

1 - bolt M12x65; 2 - bolt M12x140; 3 - bolt M12x65; 4 - bolt M10x50; 5 - bolt M12x80; 6 - mounting sleeve

Attention! It is necessary to remove and install the gearbox on a lift or an inspection ditch.

Removing

1. Remove the upper engine cover (see subsection 2.1).

2. Remove the battery and its holder.

3. Disconnect a wire from the traction relay of a starter.

4. Remove three screws 1 (see fig. 02T transmission cable bracket fasteners) fasteners and disconnect from the gearbox bracket 2 for fastening the cables of the gearbox drive.

5. Turn away a bolt of fastening and disconnect the holder 3 of a tube 4 of a drive of coupling from a transmission.

6. Unscrew the two mounting bolts and remove the clutch slave cylinder 5 from the clutch housing without disconnecting the tube from it. Secure the slave cylinder with a wire so that it does not interfere with the removal of the gearbox.

Attention! After removing the slave cylinder, never depress the clutch pedal.

7. Remove retaining ring 4 (see fig. Removing the drive levers to the gearbox), remove the selector lever 2 and set it aside with the cable.

8. Unscrew the fastening nut 5, remove the gearshift lever 6 and set it aside along with the cable.

9. Disconnect block 1 (see fig. Location of the speedometer drive speed sensor on the gearbox type 02T) with wires from the sensor 2 speed drive speedometer.

10. Unscrew the bolts accessible from above (see fig. Arrangement of attachment points of gearbox type 02T to the engine) fixing the gearbox to the engine.

11. Loosen the top starter bolt.

12. Remove the front left wheel.

13. Remove the front left wheel well cover.

14. Remove the engine crankcase mudguard.

15. Loosen the tightening bolts 3 (see fig. Silencer front pipe coupling on models with 02T gearbox) collars of fastening of the connecting plug 2, disconnect a reception pipe 1 from the resonator 4 of system of release of the fulfilled gases.

16. Remove the oxygen sensor wire from the holder 5 (lambda probe).

17. Remove the front lower bolt 1 (see fig. Fastening «mass» wires to gearbox type 02T) fastening the gearbox to the engine, thereby also disconnecting the «mass» wire 2 from the gearbox.

18. Disconnect the block with wires from the switch 3 of the reversing light.

19. Unscrew the fastening nut 4 and disconnect the bracket 5 from the box. Set the bracket with wires aside.

20. Remove the starter.

21. Disconnect both wheel drives from the flanges.

22. Disconnect the ball joint from the front suspension arm and the strut from the anti-roll bar.

23. Pull out the telescopic column 2 (see fig. V clause 10 of subsection 7.2.3) front suspension, install a wooden spacer between it and the body 1. Suspend the wheel drive with a wire, for example, to the front suspension spring. Fasten the right wheel drive as high as possible. At the same time, be careful not to damage the lacquer coating of the axle shafts.

24. Remove three bolts 1 and 3 (see fig. Vclause 26 of subsection 7.1.2.1) fasteners and remove the rear support 2 of the power unit.

25. Remove the bolt securing the gearbox to the engine, located above the right flange of the differential output shaft.

26. Hook the engine on the lifting eyes and tighten the hoist cables, taking care not to damage the hoses and wires.

27. Slightly raise the engine so as to unload the left support of the power unit, and unscrew the bolts 2 (see fig. V clause 39 of subsection 2.12.7) fixing the left support.

28. Lower gearbox 1 so that bolts 2 securing the gearbox bracket can be accessed through the front left wheel well. At the same time, make sure that the gearbox does not rest on the front suspension beam. Unscrew the two bolts 2 securing the bracket 3.

29. Loosen the lower bolts securing the gearbox to the engine (see fig. Arrangement of attachment points of gearbox type 02T to the engine).

30. Pull the gearbox away from the engine and lower it by tilting it as appropriate and pushing the engine in the opposite direction.

Installation

Install the gearbox in reverse order. When installing gearshift levers, insert slider 7 (see fig. Removing the drive levers to the gearbox), mounted on the gear selection lever, engages with the gear selector lever. Check the level and add oil to the gearbox if necessary.

Tightening torques, Nm

| Bolt of fastening of an arm to a transmission | 40, turn 90° |

| Nut of fastening of the lever of inclusion of transfers | 25 |

| Bolt of fastening of cables of a drive of a gear box | 25 |

| Bolts 1, 2, 3 and 5 (see fig. Arrangement of attachment points of gearbox type 02T to the engine) gearbox attachment to engine | 80 |

| Bolt 4 of fastening of a transmission to the engine | 45 |