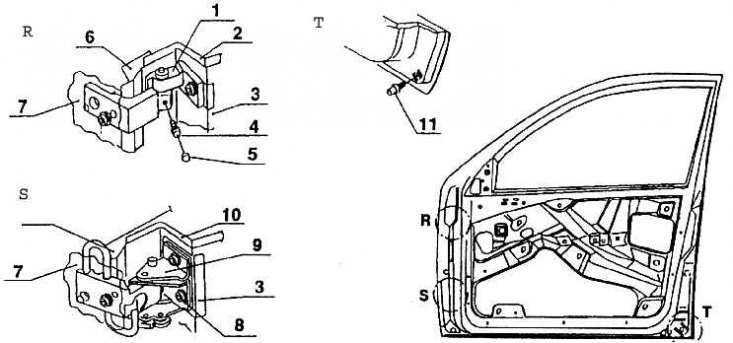

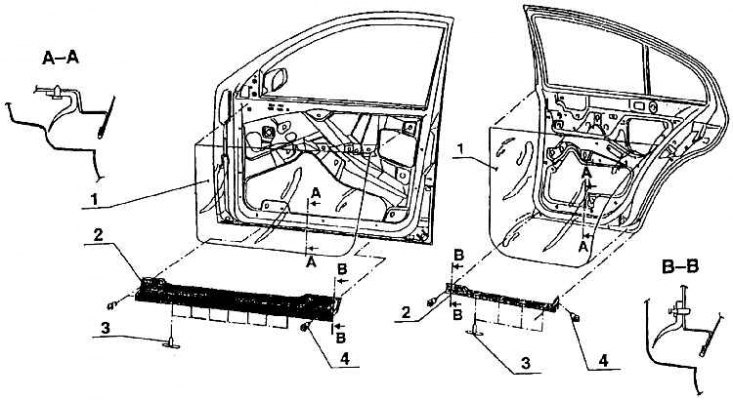

Front door hinges and safety pin

1 – upper door hinge; 2 - stiffener of the upper loop; 3 - the inner surface of the door; 4 - bolt; 5 - cork; 6 - the outer surface of the door; 7 - rack; 8 - hinge bolt; 9 - lower door hinge; 10 - stiffener of the bottom loop; 11 - security pin

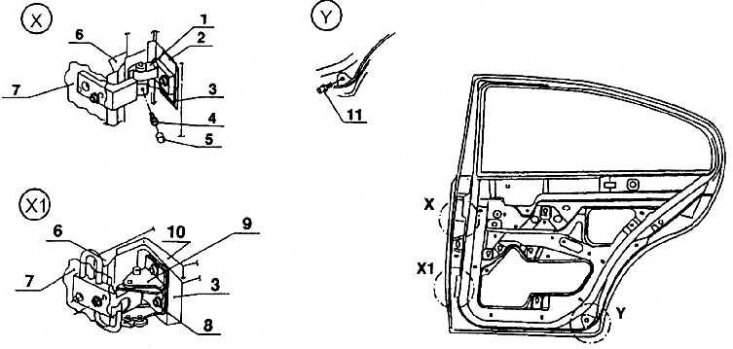

Rear door hinges and safety pin

1 – upper door hinge; 2 - stiffener of the upper loop; 3 - the inner surface of the door; 4 - bolt; 5 - cork; 6 - the outer surface of the door; 7 - rack; 8 - hinge bolt; 9 - lower door hinge: 10 - stiffener of the lower hinge; 11 - safety pin

Doors are independent mounting units of the body. Each door consists of stampings of external and internal surfaces and different stiffening ribs. The outer and inner sheets are connected along the contour by flanging (using adhesive paste). The rest of the details are welded. Expediently located stiffening ribs, squeezed out on the outer and inner sheets, give the doors considerable strength. It is further enhanced by stiffening ribs welded to the door frame in the spaces under the window openings. Stiffening ribs prevent warping of the doors in a frontal impact, the so-called frontal displacement, and in a side impact. Against side impacts, steel round tubes made of high-strength steel are still installed in the door. The front door has one tubular stiffener at the top, and the second at the bottom. There is only one stiffener in the rear door. Mounting screws for tubular stiffeners have star slots (THORX) with a special screwdriver.

The doors are suspended from the body frame, each with two hinges. The door hinges are very rigid, durable and their design solution makes it relatively easy to dismantle the doors from the body without disturbing the fit. The upper hinges are only left and right, and for the front and rear doors are the same. The lower hinges are integrated with the door stop and are also at first glance the same for the front and rear doors. But in fact it is not so. They cannot be changed during installation, since the retaining spring of the limiter on the rear doors has a different value than the limiter spring on the front doors. This is because the rear doors are lighter than the front doors.

The movable hinge leaf is screwed to the door, the fixed hinge to the body pillar. The fixed part of the hinge moves during installation so that the door can be adjusted to the surface of the body. After removing the safety elements, the hinges can be removed from the axles and put on again.

To prevent the doors from jamming during a car collision, and therefore, so that they can be opened and passengers released, steel pins are installed at the bottom of the doors. When the doors are closed, they slide into the holes of the reinforced receivers in the threshold parts of the frames of the frame doors.

The welded doors mentioned above are part of a stamped body, i. body, which forms a welded frame with installed and fitted removable parts, and in this form they enter the process of surface preparation and varnishing. In welded doors, only internal tubular stiffeners and, of course, hinges are installed.

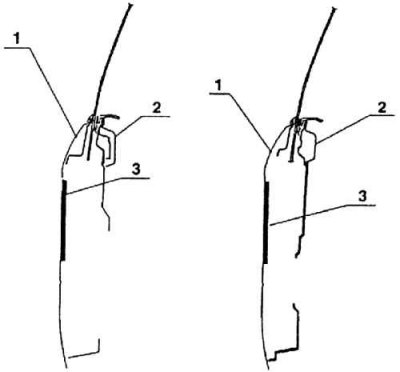

Soundproof film front and rear doors (door section)

1 - the outer surface of the doors; 2 - the inner surface of the doors; 3 - soundproof film

In the process of preparing the surface after applying the ground paint (but before applying putty) a magnetic film is applied to the inner surface of the surface sheets of all doors, which adheres to the surface during further varnishing of the body. The film performs a soundproofing function. The rest of the door fittings are mounted on the varnished doors, and the installation of the design and fittings of the doors takes place on the doors taken out of the vehicle (what is a technological novelty for Skoda cars) at a separate workplace (in parallel with the car assembly line). Only a fully assembled door is hung back on the same body again. Due to the fact that the doors are individually fitted to the frame frame, they are tied to each other.

The design and equipment of the doors includes windows, their seals and glass lowers, the locking system, door panels, and for the front doors, an external rear-view mirror.

The individual mounting sub-kits are described in the following chapters.

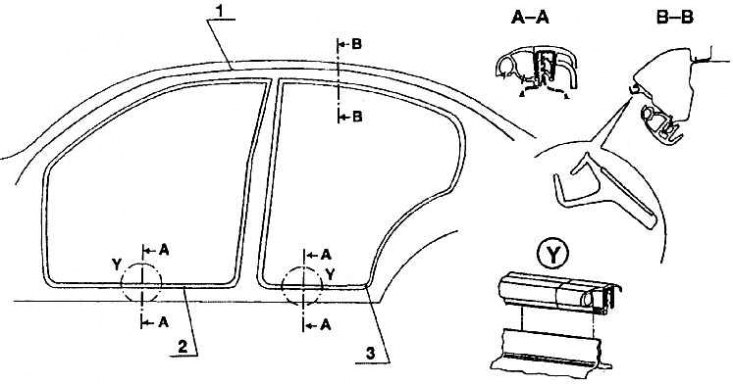

Doors of a body on a contour are condensed by three types of consolidation. The inner one is fixed on the body frame pillar, the outer upper one is glued into the recess of the body door frame pillar, but only in the upper part of the frame. This seal prevents water from penetrating into the inter-door space. The next, third seal is glued in the recess of the lower part of the door and seals the surface in contact with the body sill. Contour seal of tubular door. The elastic seal profile has, in addition to the annular sealing part, a part with a metal reinforcement embedded in a rubber lining that strengthens with a common surface. The reinforcement is flexible, which allows its profiling in the transverse direction, adapting it to the pillar of the body frame, on which the seal is mounted. In the free state, the seal forms a closed and circle. After installation on the rack of the body frame during pre-assembly, the reinforcement is pressed with a special tool. This secures the seal (ROLFORM system).

The seals issued as spare parts have a different hardening part adapted for installation by stuffing with a rubber mallet. This decision was made by the manufacturer due to the fact that not all workshops have a clamping device.

Door seal to body frame

1 - outer door seal; 2 - sealing of the front doors; 3 - rear door seal

Door seal outer bottom

1 - protective film (front, back); 2 - door seal outer bottom (front, rear); 3 - caps (7x) + (4x); 4 - caps (4x) + (2x)

There are small holes in the annular sealing part of the seal to allow air to escape from the tubular seal and thereby reduce the deformation between the sealing surfaces. Hence, the force required to close the doors is relatively small even with a significant seal pressing force.

To prevent water from leaking into the space between the doors (between the outer surface of the door and the tubular seal) on top, on the outer side of the rack along the contour of the door frame, a reed rubber seal is glued in the upper part of the contour. And the lower part of the door is sealed twice. A tubular seal is glued on the horizontal post of the inner sheet of the door and the lower part, covering the edge of the threshold after the door is closed.