Brake fluid should be changed every two years.

In order to understand the importance of following the principles of handling brake fluid (durability, miscibility, etc.), a few remarks on this subject are given below. Brake fluids have their own international classification, for example: DOT-4, ISO 4925, SAE J 1703 f and, specifically, fluids of this classification consist of a mixture of ether, glycol with polyglycol and additives of special inhibitors. Styrene-butadiene rubber cuffs are used for operation in brake systems, operating at temperatures from -50°C to + 260°C.

In general, we can say that the requirements for the properties of brake fluids are very high. For guaranteed operation of the brake system during operation in any occurring temperature conditions, the main requirement is the invariance of the composition and density of the liquid in the range from -50°C to + 260°C, no less.

In the process of braking, so much heat is transferred from the friction elements of the brakes to the liquid that its temperature reaches 130°C. With strong or prolonged braking, the temperature, of course, increases. The invariance of the composition means that all components that make up the liquid must mix well and under no circumstances separate.

In addition, the liquid should not foam during rapid changes in temperature and pressure, should not be aggressive towards the metal and rubber parts used in the system. The fluid must have both appropriate lubricating properties and, from a safety point of view, a high flash point.

Required features include both preservative capacity and the ability to mix with similar liquids, even if from different manufacturers. These and many other requirements for brake fluid contain international standards that are followed by almost all fluid manufacturers.

Unfortunately, brake fluids mix well with water, or worse, absorb it themselves. The water absorbed by the brake fluid lowers its boiling point, hence the fluid becomes unusable. It also becomes unusable and mechanical pollution as a result of abrasion of parts and dust from the atmosphere. For these reasons, the brake fluid should be changed at the time specified by the vehicle manufacturer.

From a practical point of view, you should know that high temperatures accelerate the aging of the fluid and rubber parts of the brakes. If the boiling point of the liquid is exceeded (which falls when water enters it), vapor bubbles are formed. And since vapor, unlike liquid, is compressible, and the volume of the working cylinders of the brake system is relatively small, a situation may occur in which pressing the brake pedal will not lead to the formation of the necessary pressure in the liquid and the brakes will fail. The absorption of water in the brake fluid can in some cases reach 1-1.5% after a run of 10,000 km or six months.

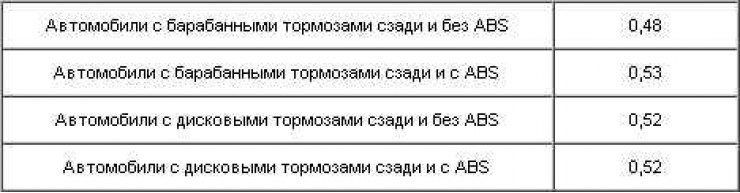

The volume of fluid to be poured into the brake system in liters