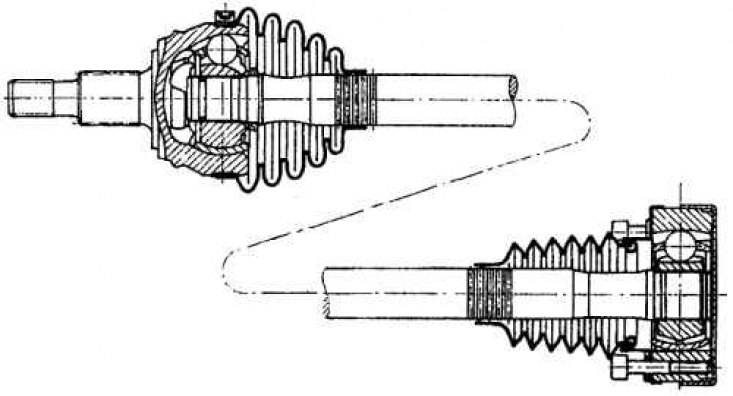

Drive Shaft Diagram

Cardan drive shafts transmit torque from the transfer case to the front drive wheels. The shafts are of unequal length and on the outer side they have ball synchronous (equal angular speeds) cardan joints.

Gearbox hinges (internal hinges) retractable, which allows you to change the length of the shafts when the wheels are cushioned. The outer and inner bands of the hinge can be moved (when rolling balls) in relation to each other by about 40 mm, which lengthens or shortens the hinge.

The splined end of the outer part of the external synchronous cardan joint is inserted into the front wheel hub. On the reverse side, at the transfer case, the flange of the outer belt of the ball bearing is attached to the gearbox leash with six socket head bolts.

The right shaft is longer and made of steel pipe. The left shaft is shorter and made of steel bar. (If the drive unit could excite shaft oscillations in a certain operating mode, different shaft materials would be chosen, and hence their masses. This ensures that the oscillation frequency lies in a region not achievable under operating conditions).

The hinges are enclosed in rubber cuffs, the integrity of which must be monitored when inspecting the car. The hinges are grease lubricated. In the event of damage, the complete cardan shaft must be replaced.