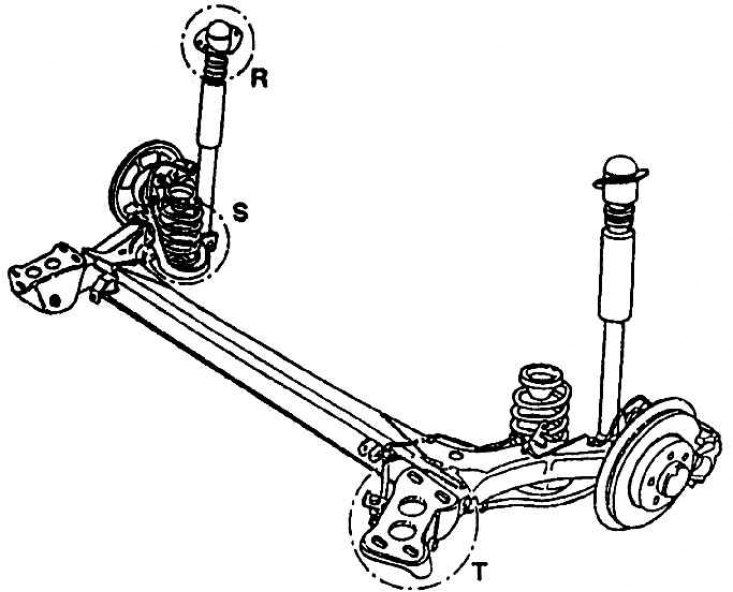

Installed rear axle assembly

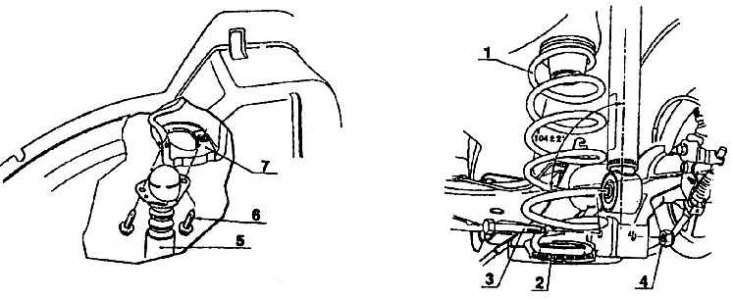

Right - detailing R (fastening of the telescopic shock absorber of the rear axle to the body), left - detail S (attaching the rear axle telescopic shock absorber to the axle carrier)

1 - rear helical spring; 2 - spring lining; 3 – a bolt of fastening of the shock-absorber; 4 - nut; 5 - telescopic shock absorber; 6 - bolt; 7 – a surface for fastening of the shock-absorber in a body

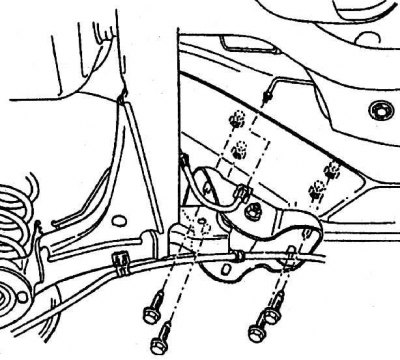

T detail (rear axle to body)

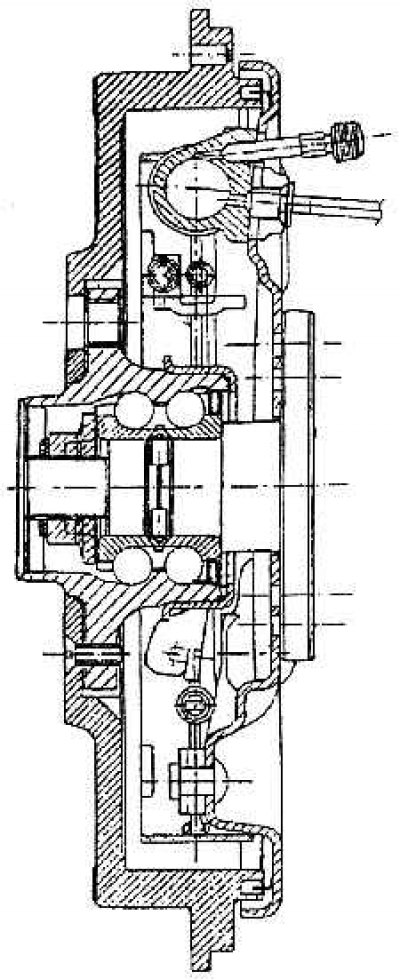

Cross-section of the rear wheel hub, which simultaneously forms the outer ring of a double-row ball bearing

The rear axle assembly in Skoda cars of the Octavia type range is an independent assembly unit. The rear axle assembly also includes wheel hubs, rear wheel brakes, springs and telescopic vibration dampers. Since the brake device is thematically related to the brakes, springs and shock absorbers to the suspension group, the description of these rear axle sub-assemblies is related to the mentioned topic (see subsection 11.3, subsection 9.4.2, subsection 9.4.3).

The rear axle is a crank formed by consoles connected to a transverse torsional element.

On the front side (in the direction of travel) the consoles are inserted into the rubber bushings of the holders, with which the bridge is attached to the car body on each side with four bolts. At the opposite ends of the consoles, the axles of the rear wheels are screwed to the flanges as an assembly. Powerful holders of helical springs and holders of telescopic shock absorbers are welded to the consoles. The dampers are behind the springs.

On the rear axle, rear wheel brakes are installed, either drum or disc.

The torsional element is a steel V-profile (channel) 6 mm thick. Side consoles welded from sheet forgings are welded to the profile. On the outer sides of their tips, plates with four holes are laser welded for screwing the axles of the wheel assemblies (bolts M 10). These axes are solved in a rather original way. They are formed by threaded flanges for mounting bolts, on which the axles are also located. Brake holders are also installed on the axle. Tapered double-row bearings are mounted on the axles with their inner ring, their outer rings are wheel bushings (see fig. Cross-section of the rear wheel hub, which simultaneously forms the outer ring of a double-row ball bearing). The sleeve is fastened with a nut with a stamped washer (it has a plastic ring at the end of the thread). The nut has an external dodecahedron for a special key. The wheel hub has five threaded holes for attaching a car wheel and one M6 thread for a countersunk bolt for attaching a brake drum or disc.

The spring holder is a stamped sheet welded on the inside of the oscillating arm.

In the lower part of the holder there is a hole, the upper exit of which is at the same time the centering for the lining of the galvanized sheet, against which the helical spring rests.

On the rear wall of the spring holder there is another holder, into which the lower eye of the telescopic shock absorber with an elastic hinge is inserted. The shock absorber is screwed with a bolt oriented horizontally.

The end coils of the helical spring at the top and bottom are compressed into a cone. In the upper part, a rubber profile lining is put on the spring, through which the spring rests against the body pit.

The upper mounting of the telescopic shock absorber is carried out by two bolts in the body bracket. The shock absorber ends with a spherical surface that allows you to deflect the shock absorber during suspension.