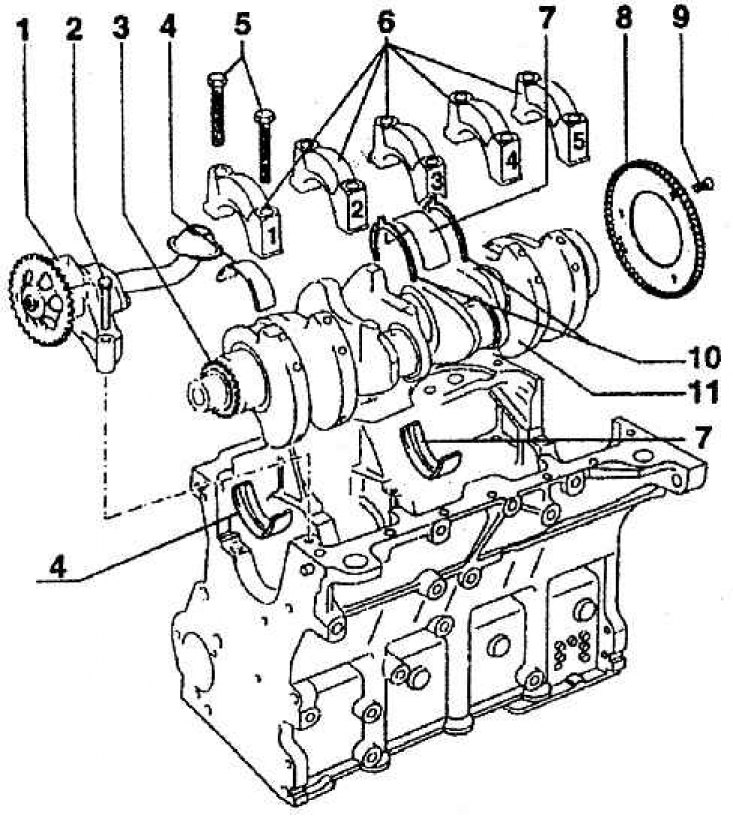

Installing the crankshaft in the engine block

1 - oil pump; 2 – a bolt of fastening of the pump (M = 25 Nm); 3 - pump drive sprocket on the crankshaft; 4 - insert - upper and lower parts of the bearing 1, 2, 4, 5; 5 – bolts of covers of bearings of a cranked shaft; 6 - bearing caps; 7 - insert of the third bearing - upper and lower parts; 8 – flywheel gear; 9 - bolt (first tighten by 10 Nm, then tighten by 90); 10 - liners for setting the axial clearance of the crankshaft; 11 - crankshaft

The engine block is made of gray cast iron with molded cylinders. The crankshaft bearing caps are also made of cast iron and are an integral part of the block. In both halves of the bearings, liners made of steel sheet with an aluminum layer are inserted. The bushings have tongue locks and a central lubrication groove.

The bearing caps are all the same, bearings 1, 2, 4, 5 have the same shells. The third bearing has a different shell, since the crankshaft axial clearance is set during installation using side guide washers.