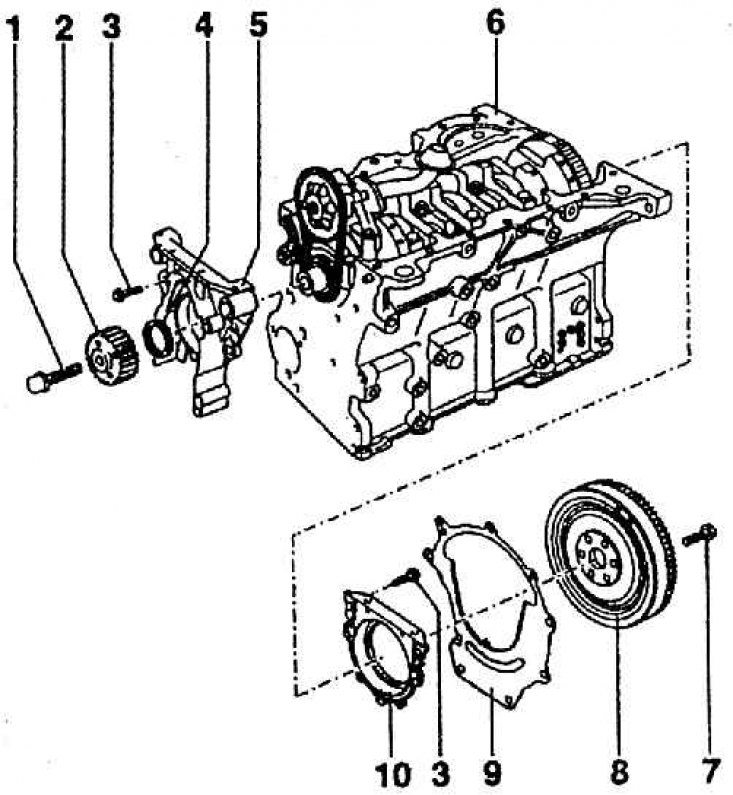

Crankshaft seals, flywheel mounting and oil pump drive with chain tensioner

1 – a bolt of a belt drive of a cranked shaft (M = 90 Nm + 90); 2 - a toothed pulley of a belt drive for driving a distribution mechanism; 3 - cover bolt (M = 15 Nm); 4 - sealing washer - gufero; 5 - front sealing cover; 6 - engine block; 7 - flywheel bolt (M = 60 Nm + 180); 8 - flywheel; 9 - adapter plate between the engine block and gearbox; 10 - rear sealing cover with goofer washer

The crank mechanism includes: crankshaft, flywheel and connecting rods with assembled pistons.

The crankshaft is made of cast steel. It has eight counterweights. Channels for supplying oil to the bearings are located across (diagonally). At the front of the shaft is a cylindrical end for the toothed pulley of the belt drive, and behind it is the oil pump drive sprocket. At the opposite end is a flange with six holes for mounting the flywheel.

The two-piece flywheel absorbs torsional vibrations well and thus significantly reduces gearbox noise. The flywheel is an assembly with a ring gear for engagement with the starter gear. It has a working surface for the friction disc of the clutch, the friction lining of which has an external/internal diameter of 216/155 mm.

The flywheel is attached to the crankshaft flange with six special M10x1 threaded bolts, fixed with adhesive mastic. The distances between the bolt holes in the flywheel and the shaft flange are uneven in order to ensure the correct position of the flywheel relative to the crankshaft, as they form a dynamically adjusted assembly.