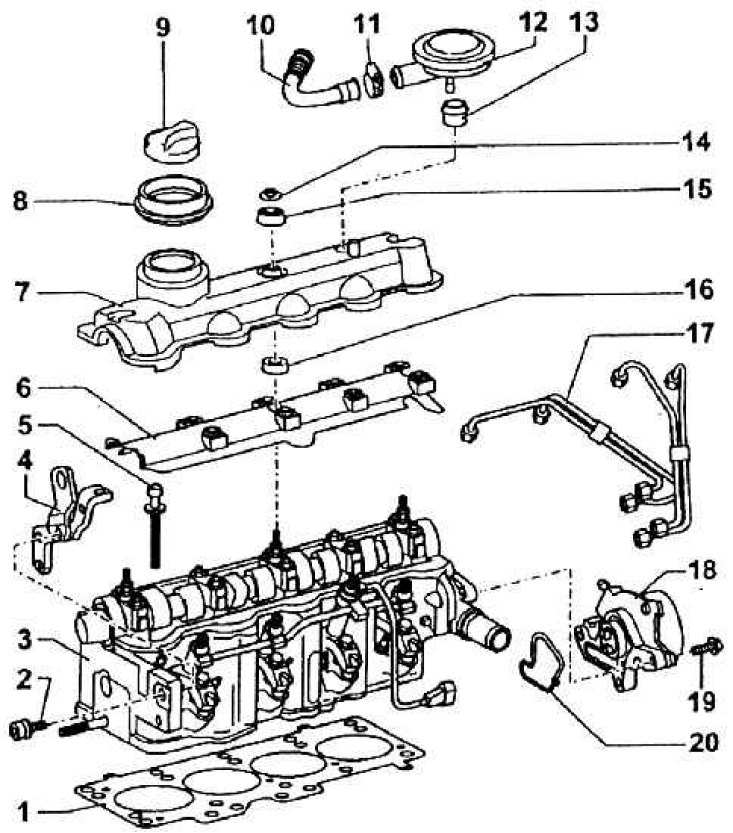

Accessories mounted on the cylinder head

1 – consolidation of a head of the block of cylinders; 2 – a bolt of fastening of an earring for slinging; 3 - cylinder head assembly installed: 4 - shackle for engine slinging; 5 – bolts of a head of the block of cylinders; 6 - a casing that protects against oil splashing; 7 – a cover of a head of the block of cylinders; 8 - sealing cuff; 9 - plug of the filler neck for oil; 10 - tube for deaeration; 11 - clamp; 12 - pressure regulating valve; 13 - seal; 14 - shaped nut; 15 – top sealing washer; 16 - the lower part of the seal; 17 - nozzle tube; 18 - vacuum pump to create a vacuum for the brake booster; 19 – a bolt of fastening of the pump; 20 - pump seal

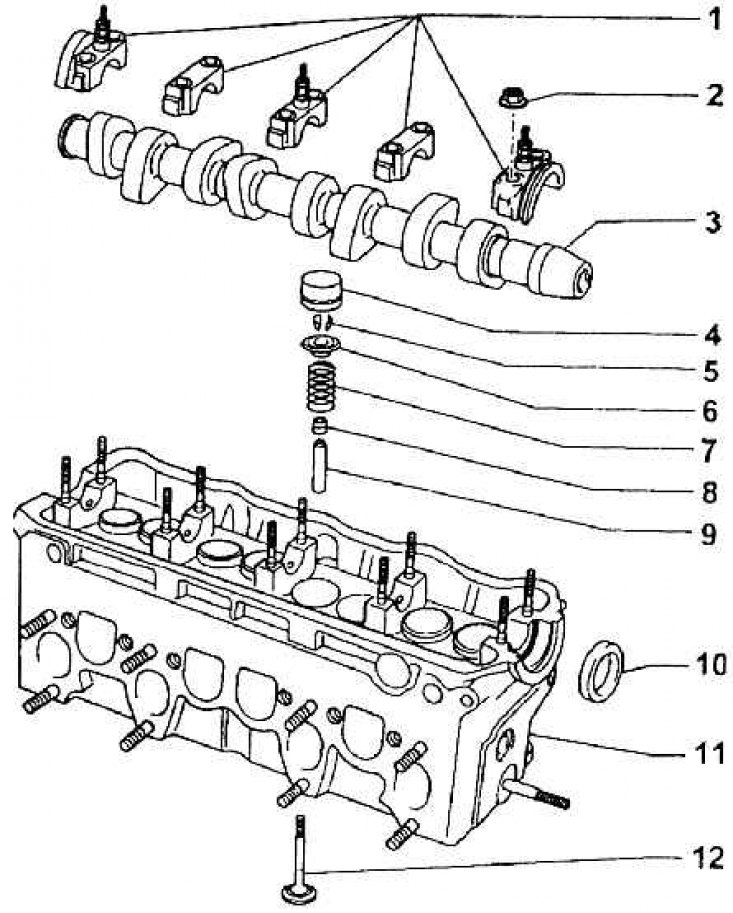

Assembly of valves and camshaft in the cylinder head

1 – a cover of bearings of a cam shaft; 2 - nuts for fastening the bearing caps to the screwed bolts (M = 20 Nm); 3 - cam shaft; 4 – hydraulic pusher; 5 - valve crackers; 6 - valve plate; 7 - valve spring; 8 - sealing the valve stem with a Guforo washer; 9 - valve guide; 10 - sealing washer of the cam shaft; 11 – a head of the block of cylinders; 12 - valve

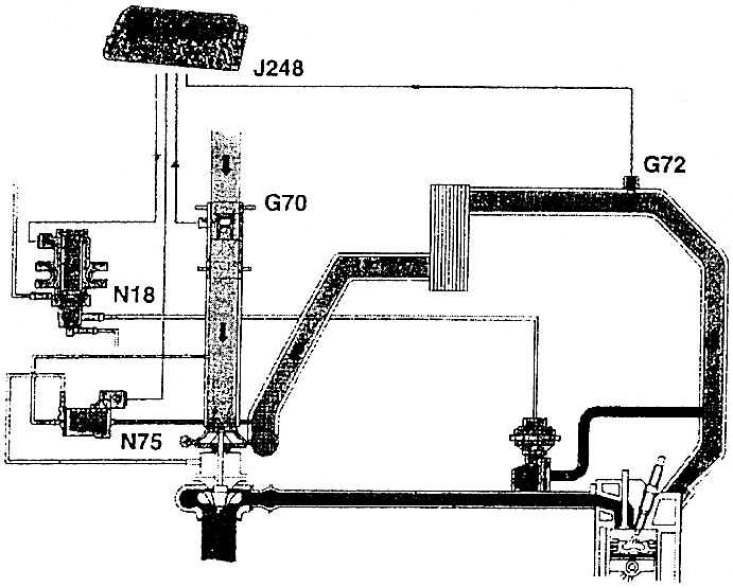

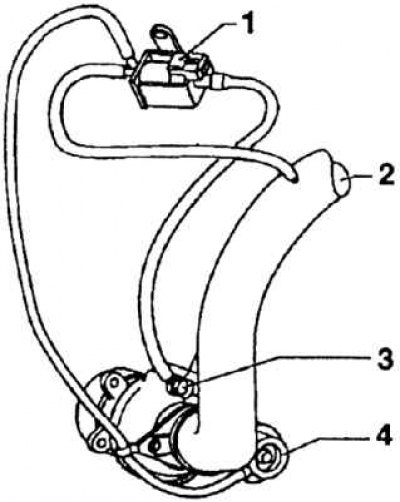

Diagram of the turbocharger (turbine drive, which increases the pressure of sucked air by exhaust gases)

J248 - control node; G72 - temperature sensor in the suction pipe; G70 - sensor for the amount of sucked air; N18 - exhaust gas return solenoid valve; N75 - boost pressure control solenoid valve

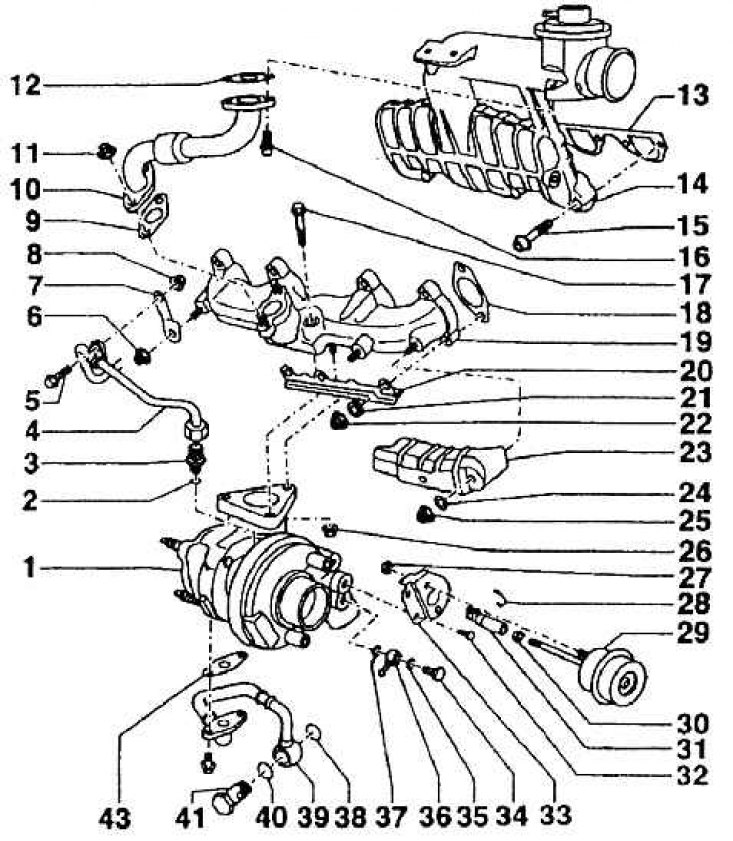

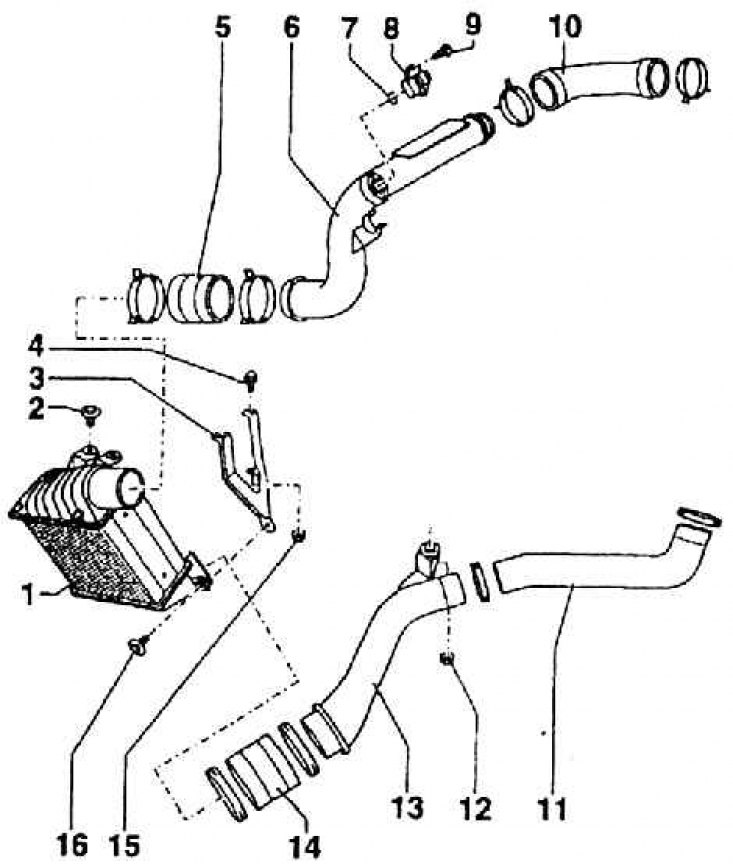

Suction pipe, exhaust manifold, turbocharger and accessories

1 - turbocharger; 2 - sealing ring; 3 - threaded fitting; 4 - oil supply line; 5 - bolt; 6 - nut; 7 – pipeline bracket; 8 - nut; 9 - seal; 10 - exhaust gas return pipeline; 11 - nut (M = 20 Nm); 12 - seal; 13 - sealing the suction pipeline; 14 - suction pipeline; 15 – a bolt of fastening of the soaking-up pipeline (M = 20 Nm); 16 – a bolt of fastening of a labor pipeline of suction of exhaust gases; 17 – a bolt of fastening of a turbocharger (M = 30 Nm); 18 - sealing the channel of the exhaust pipeline; 19 - exhaust manifold; 20 - bracket; 21 - gasket; 22 - nut (M = 25 Nm); 23 - sheet shielding diaphragm; 24 - gasket; 25 - nut (M = 25 Nm); 26 - nut (M =25 Nm); 27 - nut (M =10 Nm); 28 - retaining ring; 29 – high pressure vessel; 30 - nut (M = 10Nm); 31 - control element; 32 - bracket bolt; 33 - bracket; 34 - flow bolt (M = 15 Nm); 35 - sealing washer; 36 - input eye; 37 - sealing washer; 38 - sealing washer; 39 - return oil pipeline; 40 - sealing washer; 41 - flow bolt (M = 15 Nm); 43 - flange seal

Suction air control connection diagram

1 - solenoid valve to limit boost pressure; 2 - air supply pipe from the air filter; 3 - turbocharger with a supply for boost control; 4 - high pressure vessel for boost control valve

Cold air intake parts and radiator

1 – sucked air radiator; 2 – a bolt of fastening of a radiator; 3 - radiator bracket; 4 - bolt; 5 – hose connection; 6 - air supply tube; 7 – washer 8 – suction air temperature sensor; 9 – a bolt of fastening of the gauge (M = 5 Nm); 10 – air supply hose; 11 - air outlet hose from the radiator; 12 - bolt; 13 - air duct; 14 - hose connection; 15 - nut; 16 - bracket mounting bolt

The cylinder head, made of aluminum alloy, has eight channels: four suction and four exhaust. They point to the same side (rear in driving direction if the engine is on the vehicle). On the back, front side, there are holes for fuel injectors and glow plugs (see fig. Accessories mounted on the cylinder head).

The head casting is molded with guides and valve seats, both made of a special alloy. Valve guides can be changed, seats cannot. The automatic limitation of the working clearance of the valves is provided by means of hydraulic tappets.

Parts of the cylinder head are the camshaft bearing caps. These covers are planted each on two screwed bolts and tightened with nuts. The outer and middle covers have a boss with a bolt for fixing the head cover on the upper surface. Camshaft bearings missing bushings (see fig. Assembly of valves and camshaft in the cylinder head).

The 1.9 TDI-66 kW engine has an ONS valve timing system, or with a camshaft in the cylinder head. Therefore, the camshaft is included in the cylinder head assembly kit.

The cylinder head assembly is attached to the crankcase with ten special bolts. The order of their tightening is shown in fig. The order of tightening the bolts on the cylinder head; when unscrewing, they act in the reverse order, i.e. from bolt number 10.

Maximum flatness of the seating surface of the cylinder head (warpage) should not exceed 0.1 mm. When remounting the head, the seal and head bolts must always be changed. Head mounting has its own characteristics known to all Skoda service departments. By the way, the tightening of the head bolts is carried out in four stages. Bolts First (always in the order shown in Fig. The order of tightening the bolts on the cylinder head) are tightened with a torque wrench to M = 35 Nm, at the next stage they are again tightened with a torque wrench to M = 60 Nm, with the third tightening, all the bolts are tightened by 90°and with the fourth - by another 90°. This is the final stretch.

With the 1.9 TDI-66 kW engine, the compression pressure is very important. It is measured at an oil temperature of at least 30°, after unscrewing all the glow plugs. First disconnect the valve connectors for disconnecting the fuel and the connectors for the fuel quantity control device on the fuel pump. Then a barograph with a screw adapter is installed on one of the cylinders. The pressure is measured while cranking the engine using the starter.

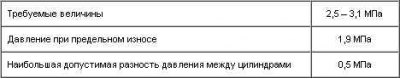

Compression pressure - overpressure

The camshaft timing gear is driven from the crankshaft by a toothed belt drive. It simultaneously drives both the coolant pump and the fuel pump. Their mutual arrangement can be seen in Fig. Belt drive timing gears and coolant pump.

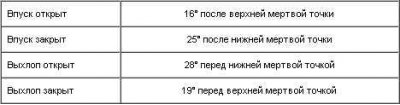

Valve timing (with piston stroke 1 mm and piston play 0 mm)

At the left end (if the engine is installed on the car) The camshaft houses a vacuum pump that provides vacuum for the brake booster.

Air suction system with turbocharger and exhaust gas return system (see fig. Diagram of the turbocharger (turbine drive, which increases the pressure of sucked air by exhaust gases), pic. Suction pipe, exhaust manifold, turbocharger and accessories (detailing of individual nodes)).

The air supply from the air filter consists of two parts. The elastic part provides the possibility of mutual movement between the engine and the air filter, in the hard part connected to the engine, there is also an engine crankcase deaeration fitting. The connection scheme for air suction regulation is shown in fig. Scheme of connecting the regulation of the sucked air. Installation of the sucked-in air radiator and the procedure for its installation is shown in fig. Cold air intake parts and radiator.

The aluminum casting of the suction pipe is bolted to the cylinder head and sealed with a shaped seal. A mechanical deaeration valve is also part of the pipeline.

The exhaust manifold is a cast iron with a flange for connecting the turbocharger flange, mounted on three screwed bolts with nuts. The turbocharger, which increases the pressure of the sucked air with the help of a turbine, is driven by exhaust gases. The lubrication of its bearings is included in the engine lubrication system. The front part of the exhaust pipe is connected to the turbocharger by an elastic element. The manifold is mounted on the screwed-in bolts of the cylinder head and secured with nuts. Separate channel seals are inserted between the head and the pipeline.

The air intake system is complemented by an exhaust gas return system. The system is controlled by the control node (J 248) through the exhaust gas return solenoid valve (N 18) to mechanical valve (AGR). It has a cone-shaped valve lifter, which makes it possible to change the cross section of the hole at different valve positions.