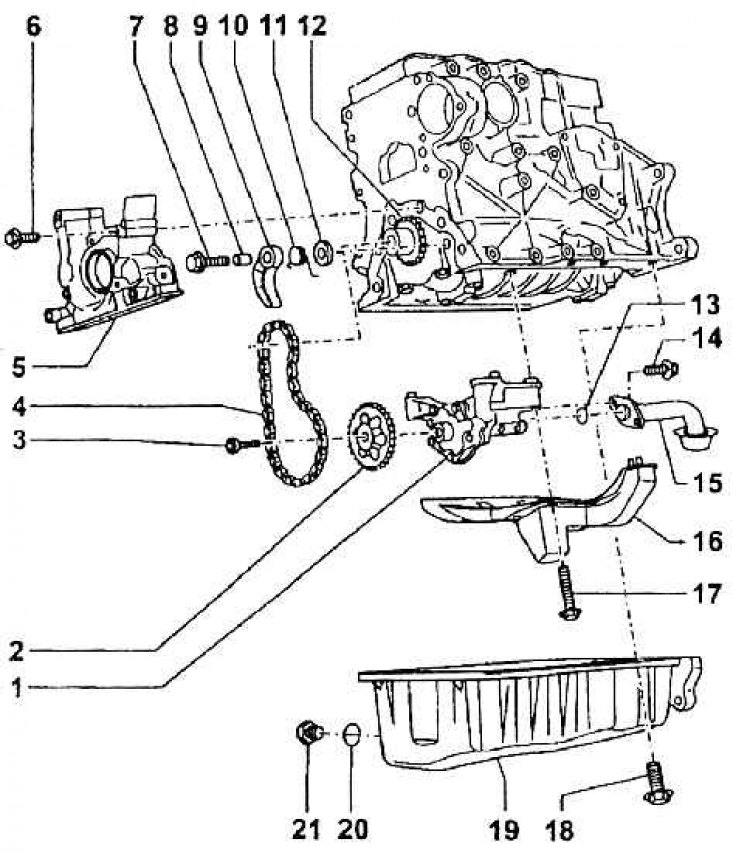

Auxiliary equipment of the engine lubrication system

1 - oil pump; 2 – an asterisk of a drive of the oil pump; 3 – a bolt of fastening of an asterisk to a shaft of the pump (M = 25 Nm); 4 – a chain of a drive of the oil pump; 5 - front cover; 6 – a bolt of fastening of a forward cover (M = 15 Nm); 7 – a bolt of the tension device of a chain (M = 25 Nm); 8 - bushing; 9 - chain tensioner; 10 - tensioner spring; 11 - gasket; 12 – an asterisk of a drive of the oil pump on a cranked shaft; 13 - washer-seal of the suction grid; 14 - bolt; 15 - a tube with a suction grid for oil; 16 – a casing of bearings of a cranked shaft; 17 - casing mounting bolt (M = 15 Nm); 18 - bottom cover mounting bolt (M = 15 Nm); 19 - engine crankcase; 20 - sealing washer; 21 - bolt for descent (M = 30 Nm)

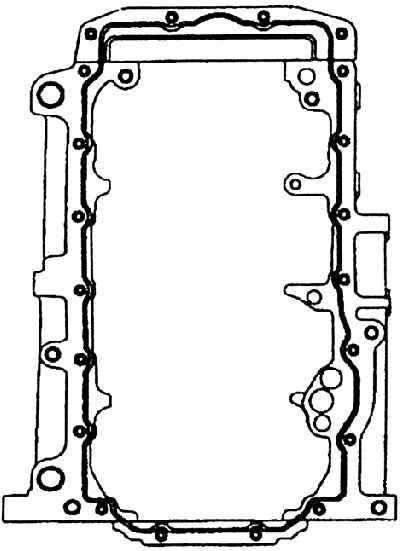

The route for applying silicone sealing mastic to the seating surface of the lower engine cover

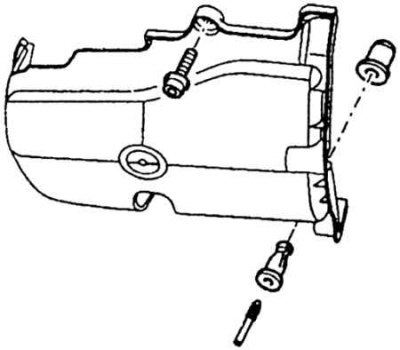

Soundproof casing of the bottom cover of the engine

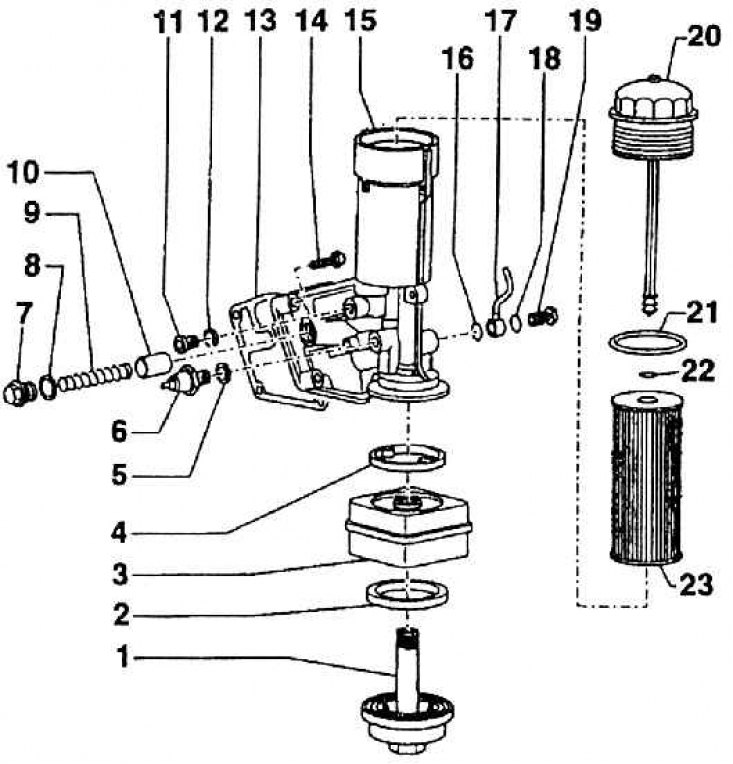

Radiator and oil filter

1 - locking bolt (M = 25 Nm); 2 - seal; 3 - oil cooler; 4 - seal; 5 – sealing washer of the baroscope; 6 – the switch of a control bulb of pressure of oil (baroscope) (M = 25 Nm); 7 - locking bolt of the pressure valve; 8 - sealing washer; 9 - spring; 10 - piston of the overpressure valve; 11 - locking bolt (M = 10 Nm); 12 - sealing washer; 13 - seal; 14 – a bolt of fastening of an arm of the oil filter and a radiator; 15 - oil filter bracket; 16 - sealing washer; 17 - supply oil pipeline; 18 - sealing washer; 19 - flow screw; 20 - filter cover (M = 25 Nm); 21 - sealing ring of the filter cover; 22 - ring-seal of the centering bolt; 23 - oil filter filter tab

The lubrication is circulating, under pressure, the oil flow completely passes through the filter. The oils that can be used in the engine are listed in the SERVICE INSTRUCTIONS. Oil must meet TL 52 107 (VW 50500). The oil is concentrated in the engine crankcase and from there it is sucked in by a gear oil pump and supplied under pressure to the appropriate places in the engine. Oil pump (Duocentric) with overpressure valve 1.2 MPa driven by a roller chain from the crankshaft sprocket. The chain is under constant tension. At pump speed 1000-1/min and oil temperature 80°C (oil 20 SAE) the recommended amount is 7.1 l, i.e. about 6 kg per minute at a pressure of 0.4–0.5 MPa. Under the crankshaft of the engine there is a sheet casing, a partition that prevents the rapid overflow of oil. The crankcase made of aluminum casting is combined with the front and rear covers and together with them is sealed to the crankcase with silicone mastic. The installation of these nodes is shown in fig. Auxiliary equipment of the engine lubrication system and fig. The route for applying silicone sealing mastic to the seating surface of the lower engine cover. Under the crankcase there is also a soundproof casing (see fig. Soundproof casing of the bottom cover of the engine).

An oil cooler and filter are also embedded in the lubrication system. An overpressure valve is also fixed in the oil filter bracket, which provides the possibility of reverse oil bypass. There is also a baroscope on the bracket (it is painted with gray paint, 0.09 MPa, turns on at a pressure of 0.015±0.01 MPa. The oil filter is equipped with a replaceable paper filter insert (see fig. Radiator and oil filter).

The oil dipstick is a steel strip inserted into a tube installed in a hole in the crankcase of the engine and attached at the top with a bracket to the crankcase.