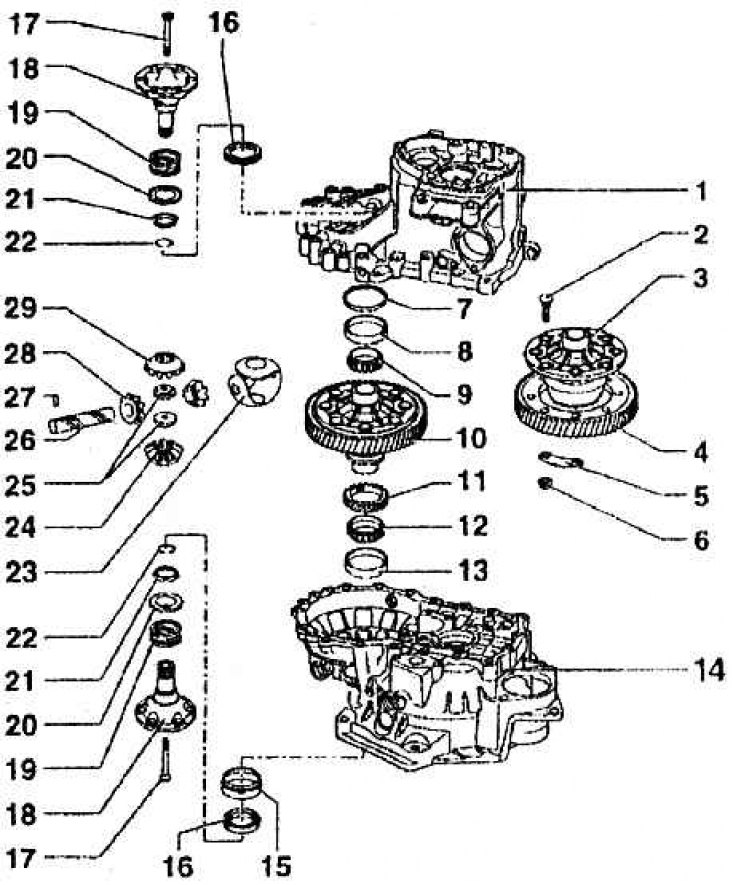

Attention! Before assembling, heat the tapered roller bearing inner race to 100°C. Replace both tapered roller bearings together.

In case of replacement of tapered roller bearings, differential box, gearbox housing and clutch housing, adjust the differential

Differential

1 - gearbox housing; 2 - screw; 3 - differential box (screwed to the pinion for driving the flanged output shafts, in gearboxes with compression springs there is a chamfer behind the flanged shafts for fastening the conical rings, pos. 21); 4 - gear for final drive (riveted at the factory, mount, preheat to a temperature of 100°C, install on the differential box, forms a pair with the secondary (slave) shaft; when replacing, change together; 5 - sheet metal lining; 6 - nut, 70 Nm; 7 - adjusting gasket (for differential); 8 - the outer ring of the tapered roller bearing; 9 - the inner ring of the tapered roller bearing; 10 - differential box (with a riveted gear, rivets must be drilled to replace the gear; attaching the gear with screws; in gearboxes with compression springs, there is a chamfer behind the flanged shafts for attaching the conical rings, pos. 21); 11 - speedometer drive gear (before pressing in the inner ring, install it all the way to the differential box); 12 - the inner ring of the tapered roller bearing; 13 - the outer ring of the tapered roller bearing; 14 - clutch housing; 15 - sleeve (for fastening the sealing ring, pos. 16); 16 - sealing ring; 17 - conical screw, 25 Nm (to secure the shaft with the flange, screw it onto the threaded part, pos. 25); 18 - shaft with flange (with thread for conical screws); 19 - compression spring for a shaft with a flange (installed behind the flanged shaft); 20 - thrust ring (mounted in combination with compression springs behind the flanged shaft; assembly position: flange - to the compression spring, shoulder - to the conical ring); 21 - conical ring (mounted in combination with compression springs behind a flanged shaft with grooves to engage the thrust ring; assembly position: cone pointing towards differential box); 22 - retaining ring (mounted in combination with compression springs behind the flanged shaft; when the flanged shaft is disassembled, it holds the conical ring, thrust ring and compression spring in this position; 23 - spherical insert (install lubricated with gear oil); 24 - conical satellite differential, large; 25 - threaded part (mounted in combination with compression springs behind the flanged shaft); 26 - the axis of the conical satellites of the differential (press out with a mandrel); 27 - clamping sleeve (for locking the axis of the conical pinion gears of the differential); 28 - conical satellite differential, small; 29 - conical satellite differential, large