Note: Replace screws that are tightened to the specified angle. Replace self-locking nuts and screws, as well as O-rings and gaskets. Fittings, as well as air ducts and hoses must be degreased before installation. To secure all hose connections, use original spring clamps, similar to those installed at the factory. During installation, all cable ties should be placed in their original positions. When carrying out assembly work, especially in the engine compartment due to its dense layout, the following regulations must be observed. Highways of all types (fuel, hydraulic, coolant, coolant, brake fluid, vacuum) and wires should be routed in the original factory order (using appropriate fasteners). To prevent damage to hoses, pipes or wires, sufficient clearance must be maintained to all moving or hot parts.

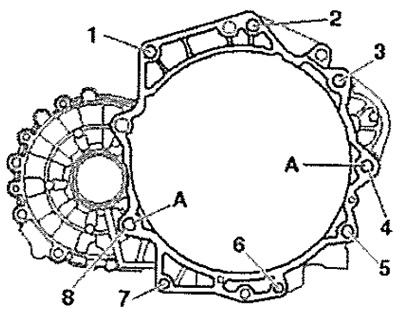

Install intermediate plate. If the cylinder block does not have bushings -A- for centering the engine and gearbox, install them.

Note: Details shown for vehicles with manual gearbox.

Vehicles with manual gearbox

If a needle bearing is installed in the crankshaft, then it must be removed. If the clutch release bearing is worn, replace it. Lightly lubricate input shaft splines with clutch disc spline grease. Check the centering of the clutch disc,

Vehicles with DSG gearbox

If there is no needle bearing in the crankshaft, install it.

All

Screw gearbox to engine. Install gearbox support. Raise power unit with engine bracket -T10497-.. Insert power unit into body. Screw in bolts -arrows- for engine support by hand, but do not tighten. First screw in bolts -arrows- for gearbox support by hand until they are in contact with the bearing surface.

Note: Shown as an example is a gearbox support for vehicles with dual clutch gearbox 0CW. The screws are finally tightened when adjusting the subframe.

Remove engine bracket -T10497- from engine. Install starter. Install charge air cooling pump -V188-. Install air duct.

Vehicles with DSG gearbox

Install on the gearbox and adjust the selector cable.

All

Install the inlet pipe. Install intake pipe. Install drive shafts. Install the air conditioner compressor. Install poly V-belt. Install the engine control unit. Install differential pressure sender -G505-. Connect clutch slave cylinder. Pump the clutch. Install cables with cable supports. Powertrain mount adjustment. Install the battery bracket. Electrical connectors and cabling. Connect vacuum hoses. Install the air filter. Check oil level.

Carefully! Excessive voltage creates a risk of damage to the control units. Do not use the charger to start the engine!

Remove air from the fuel system. Connect coolant hoses with quick coupling. Fill up the coolant. Install the subframe. Install the front fenders.

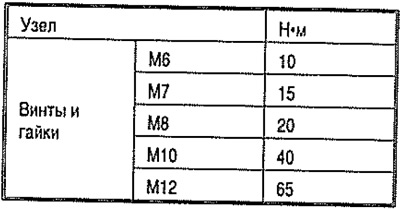

Tightening torques

Note: The tightening torques apply to lightly greased or oiled, phosphated or oxidized bolts and nuts. Additional lubricants allowed (e.g. motor or gear oils), except graphite-containing. Do not use degreased parts. The torque tolerance is±15%.