Note: If a large amount of metal chips or wear marks are found in the engine during repairs, this may be due to damage to the crankshaft bearings and connecting rods. To prevent damage in the future, after repair, the following work must be performed: thoroughly clean the oil channels; replace oil nozzles, engine oil cooler and oil filter. Piston cooling nozzle and pressure reducing valve.

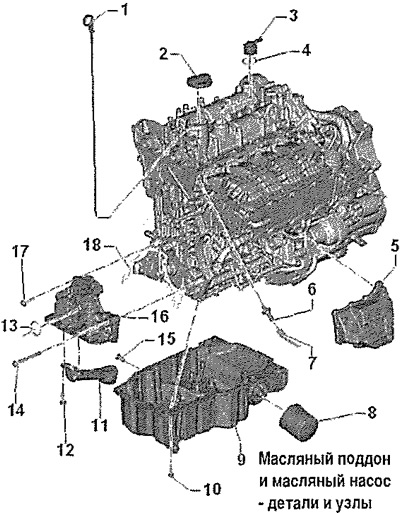

1. Level indicator

2. Lid

3. Bleeding nipple: Install in proper position

4. O-ring: replace; moisten with oil before installation

5. Screen: oil separator

6. Low oil pressure switch F378: screw in 3 turns by hand; 20 Nm

7. Connector

8. Oil filter, 20 Nm: moisten the seal with oil before installation; if the outer surface is damaged, the oil filter must be replaced

9. Oil pan

10. Bolt: replacement

11. Inlet pipeline 12.8 Nm

13. O-ring for oil pump drive

14. Tensioner bolt

15. Oil drain plug, 30 Nm

16. Oil pump

17. Bolt: replace

18. Gasket: replace; follow the guide pins for positioning