Attention. If you are in traffic, turn on your hazard warning lights and place a warning triangle at the prescribed distance! Stop the vehicle at the maximum possible distance from the traffic flow. The place should be as level as possible and have a solid base (soil). If the vehicle has subsequently been fitted with tires or rims other than those fitted at the factory, the instructions must be observed. Observe the following lifting rules. If you are changing a wheel on a sloping road, support the wheel on the opposite side of the vehicle with a stone or similar object to prevent the vehicle from rolling. Secure the jack base against possible displacement using suitable means. Soft, slippery ground under the jack support can cause it to move and the vehicle to fall off the jack. Therefore, always place the jack on a solid base or use a strong pad of sufficient area. On slippery surfaces such as cobblestones, tiles, etc., use a non-slip pad (e.g. rubber mat). Install the jack only at the attachment points on the vehicle body designed for this purpose. Raise the vehicle always only with the doors closed. When the vehicle is jacked up, crawling under the vehicle and placing body parts under it, such as arms or legs, is strictly prohibited. Do not start the engine of a vehicle that is on a jack - risk of injury! The tightening torque of the wheel bolts for steel and light alloy wheels is 120 Nm. If the security bolt is overtightened, both the security bolt itself and the adapter can be damaged.

Remove the full size wheel cover or bolt caps. Loosen the lock bolt first and then the rest of the wheel bolts. Raise the vehicle so that the wheel to be changed does not touch the ground. Loosen the wheel bolts and place on a clean pad (rag, paper, etc.,), Carefully remove the wheel. Install the spare wheel and screw them on by hand. Lower a / m. Tighten the opposite wheel bolts alternately with a wheel bolt wrench (criss-cross). Finally, tighten the security bolt. Install the wheel cap or wheel bolt caps.

Note: All wheel bolts must be clean and free to move (should twist easily). It is strictly forbidden to lubricate the wheel bolts! When installing wheels with a given direction of travel, take into account the position of the wheel. If, when changing a wheel, you find that the wheel bolts are rusty and difficult to tighten, these bolts must be replaced before checking the tightening torque. Before checking the tightening torque, drive carefully and only at a uniform speed.

Changing a wheel: loosening the wheel bolts

Install the wheel bolt wrench on the wheel bolt as far as it will go (1). Grasp the end of the key and turn it about one turn counterclockwise.

Puff

Install the wheel bolt wrench on the wheel bolt as far as it will go (1). Grasp the end of the wrench and turn the bolt clockwise until it is properly tightened.

Attention! Loosen the wheel bolts only a small amount (about one turn), until the vehicle is jacked up! Otherwise, the wheel may come off and fall off - risk of injury! If the bolt cannot be unscrewed by hand, you can, being careful, press on the end of the key with your foot. At the same time, hold on to the vehicle so as not to fall.

(1) To unscrew and tighten the security bolts, use the appropriate adapter.

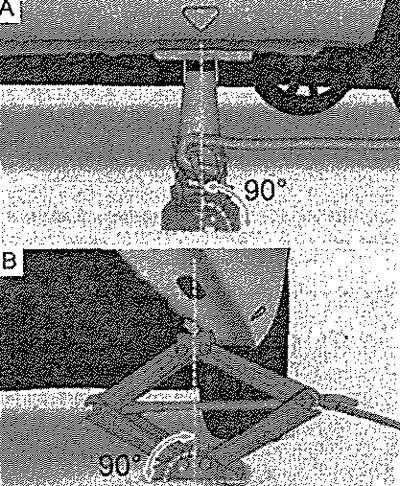

Support points for the jack

Jack installation

Place the jack under the anchor point closest to the faulty wheel. The reference point is directly below the recess in the threshold. Attach the jack handle to the socket on the jack. Turning the handle, bring the jack to the reference point so that its grip is under the vertical edge of the threshold. Set the jack so that the catch is on the edge - B. Make sure that the jack foot rests on a level base with its entire surface, and is located vertically below the point where the catch is installed on the edge of the threshold - A. Continue to raise the jack until the wheel breaks off the ground.

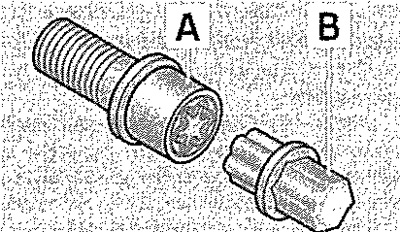

Conditional image: bolt-secret and adapter

It is possible to unscrew or tighten the security bolts only with the help of an adapter. Remove the bolt cover. Insert the adapter B with the toothed side all the way into the inner slot of the security bolt A so that only the outer hexagon protrudes. Install on adapter B the wheel bolt wrench until it stops. Loosen and tighten the wheel bolt. After removing the adapter, install the cover on the security bolt. Check the tightening torque with a torque wrench as soon as possible.

Note: Write down the code stamped on the end face of the adapter or head of the security bolt. A spare adapter can be purchased from this number if needed. The adapter for wheel bolts should always be stored in the vehicle. It should be in the container with the on-board tool. A set of locking wheel bolts and an adapter can be purchased from a SKODA dealer.