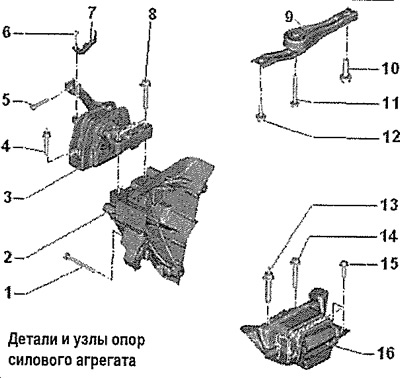

1. 40 Nm and tighten by 90° (1/4 vol.): replace

2. Engine mount bracket

3. Motor support: with bracket

4. 40 Nm and tighten by 90° (1/4 vol.): replace

5. 20 Nm and tighten by 90° (1/4 vol.): replace

6. 8 Nm

7. Bracket

8. 60 Nm and tighten by 90° (1/4 vol.): replace

9. Lower support of the power unit

10. 130 Nm and tighten by 90° (1/4 vol.): replace

11. 50 Nm and tighten 90' (1/4 vol.): replace

12. 50 Nm and tighten 90' (1/4 vol.): replace

13. 60 Nm and tighten by 90° (1/4 vol.): replace

14. 60 Nm and tighten by 90° (1/4 vol.): replace

15. 50 Nm and tighten by 90° (1/4 vol.): replace

16. KP support

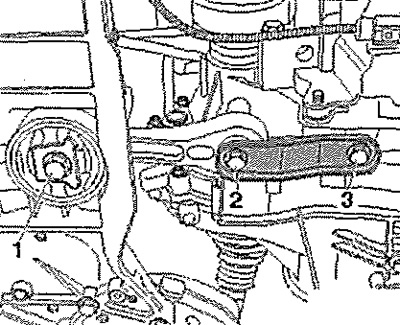

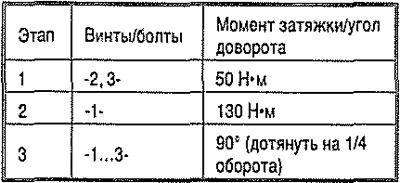

Removal and installation of the lower support of the power unit

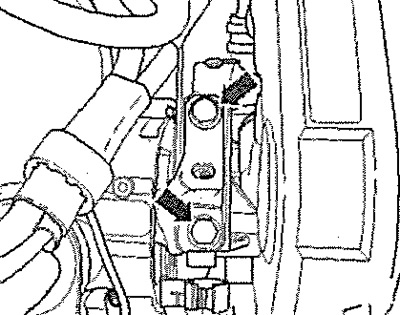

Unscrew bolt -1-. Remove bolts -2- and -3- and remove spacer.

Installation in reverse order.

Note: Screws/bolts that are tightened to the specified angle must be replaced.

Tighten the bolts step by step in the sequence shown.

Power unit mount adjustment

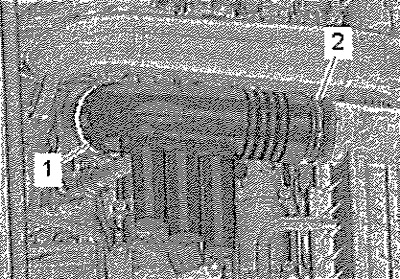

Remove battery bracket. Loosen clamps -1- and -2- and remove air pipe. Remove the air filter housing. Remove the wiper arms. Remove the plenum box cover. Remove the caps on the threaded connections of the cups of the front shock absorber struts.

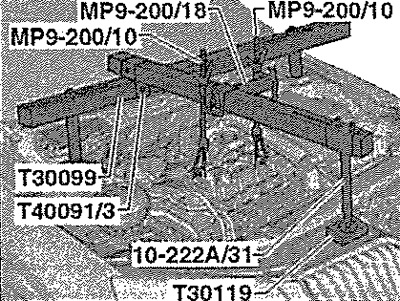

Fit support bracket -T30099- as shown in illustration. Install the carabiners on the engine lugs. Slightly tighten the power unit with the spindles, but do not lift.

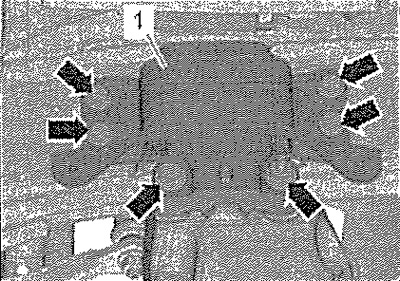

Unscrew screws -arrows- for engine support one by one and replace them if this was not done when installing the engine. Fasten the screws.

Unscrew screws -arrows- of gearbox support -1- one by one and replace them if this was not done when installing the engine. Fasten the screws.

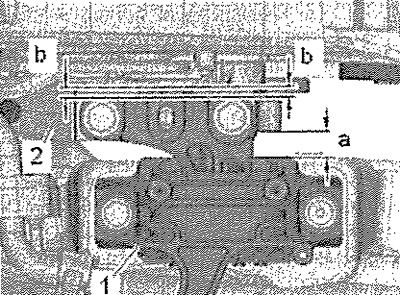

Align the power unit with a pry bar so that the following dimensions are observed: Between the engine support -2- and the engine bracket -1- there must be a distance -a-= 10 mm. The edge of the cast engine support bracket -2- must be parallel to the console -1-. Size -b- = size -b-.

Note: The distance -a-= 10 mm can also be checked using, for example, a suitable rod.

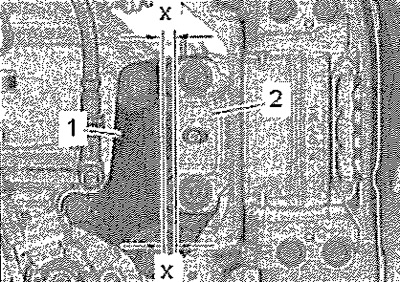

Tighten the mounting bolts. Make sure that edges of console -2- and gearbox support -1- are parallel on gearbox side. Size -x- = size -x-. Tighten gearbox mounting bolts.

Installation in reverse order.