Note: The engine is removed downwards with the gearbox. After installing the engine, it is necessary to reinstall all cable ties that are removed or cut off during dismantling in the same place. Leave the ignition key in the ignition to prevent the steering column from locking. Risk of injury from fuel under high pressure. Before opening the high pressure circuit of the injection system, the fuel pressure must be reduced to residual pressure.

Relieve the fuel pressure in the high pressure circuit. Open cap -arrow- of expansion tank.

Attention! Risk of burns from hot steam or hot coolant. When the engine is hot, the fluid in the cooling system is under pressure. To relieve pressure, cover the expansion tank cap with a rag and carefully unscrew, gradually relieving pressure.

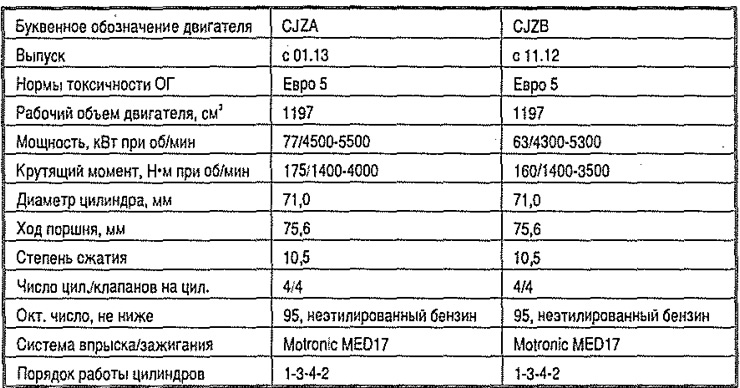

Engine Specifications

Some points of removal and installation are described in 1.8 and 2.0 liter engines.

Remove both front wheels. Remove soundproof cover. Remove both front fender liner. Unplug electrical connector -2- at radiator outlet coolant temperature sender -G83- -3-. Drain coolant.

Carefully! Only install a used belt in the same direction of travel. Incorrect installation can lead to the destruction of the belt! Before removing the V-ribbed belt, mark the direction of its running with chalk or a felt-tip pen.

Vehicles with air conditioning

Attention! Do not open the refrigerant circuit of the air conditioner.

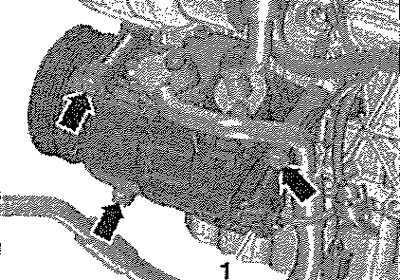

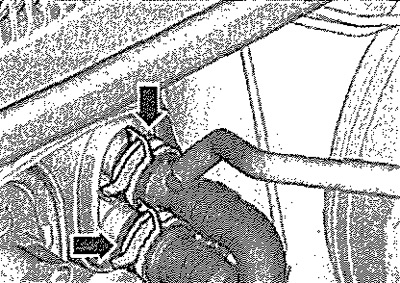

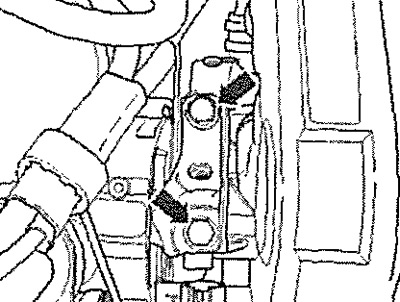

Remove poly V-belt. Unplug connector -1- at air conditioner compressor control valve -N280-. Unscrew bolts -arrows- for air conditioner compressor.

Carefully! Risk of damage to refrigerant pipes and hoses. Do not stretch, bend or kink pipes and refrigerant hoses.

Remove air conditioner compressor together with refrigerant hoses, move to right and tie up.

All

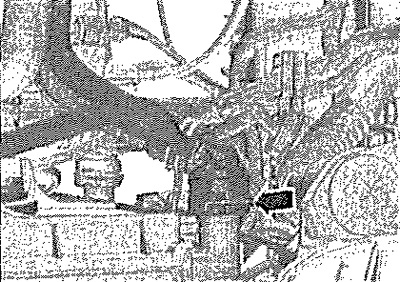

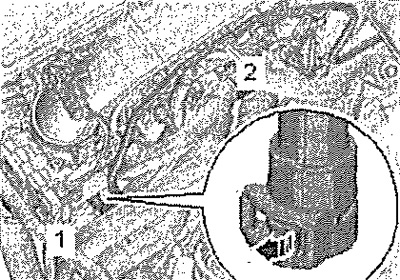

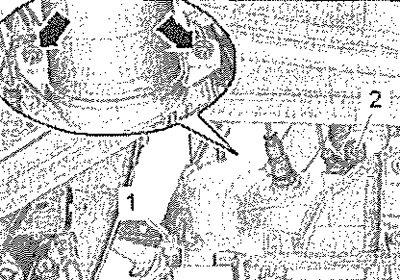

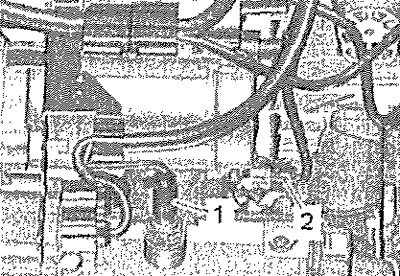

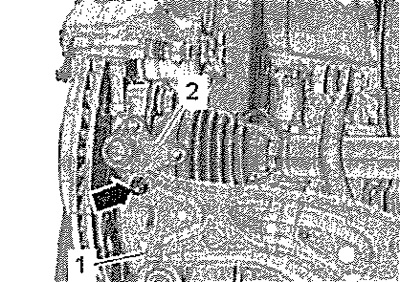

Loosen clamp -1- and remove air pipe. Release screws -2- on left and right. Detach from the front support panel and remove the air duct.

Raise clip -arrow- and disconnect upper left coolant hose from radiator.

Note: Depending on the vehicle version, 3 versions of the radiator are fitted.

Vehicles with radiator version 1

Raise clamp -arrow- and detach upper right hose from charge air cooler.

Vehicles with cooling radiator versions 2 and 3

Raise retaining clip -1- and detach coolant hose from charge air cooler.

All

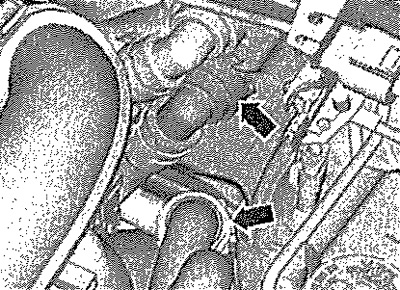

Raise the retaining clip and loosen the clamp and detach both coolant hoses -arrows-.

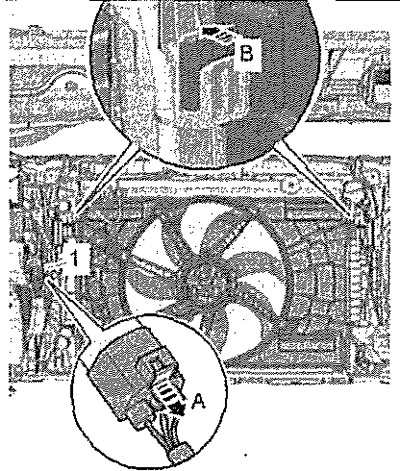

Unplug electrical connector -1-, to do this push catch -arrow A- backwards and unlock downwards.

Remove fan shroud. Disconnect battery. Remove the battery and its bracket. Unlock catch -arrow- and detach vacuum hose -1-. Detach vacuum hose from mounts on air duct -2-.

Vehicles without auxiliary heater

Open clamps -arrows- and detach coolant hoses from heater heat exchanger.

Vehicles with auxiliary heater

Raise the retaining clip and loosen the clamp and detach both coolant hoses -arrows-.

All

Unscrew screw -2- and remove screw clamp. Remove screw -1-, unscrew nut -arrows- and tie up catalytic converter.

Release screws -arrows- and remove bracket.

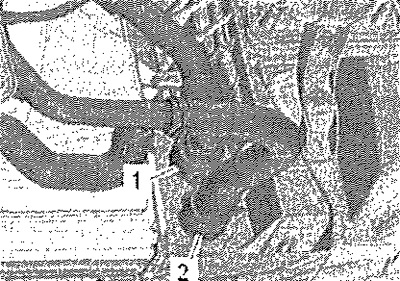

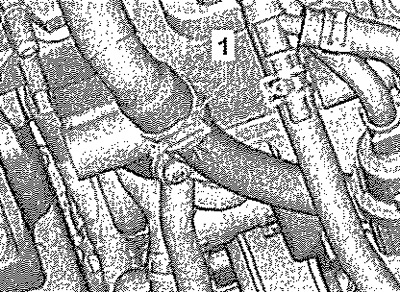

Loosen clamp -1 - and detach coolant hose.

Attention! Risk of injury from fuel. To relieve fuel pressure before opening the fuel system, place a clean rag around the connection and carefully disconnect. Danger of contamination. When working on the power system, observe the rules for maintaining cleanliness.

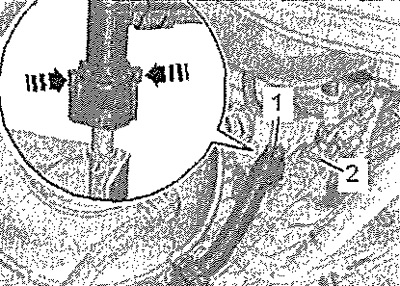

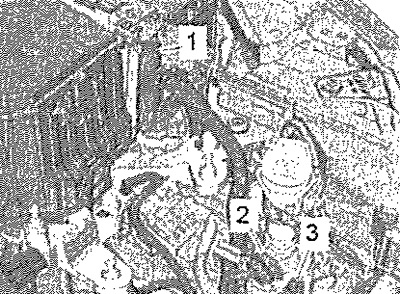

First press hose coupling -1- downwards, then compress clamps -arrows-. Remove the hose coupling with the clamps pressed. Press the latch on the hose leading to the canister -2-. Disconnect the hose and release it from the fittings.

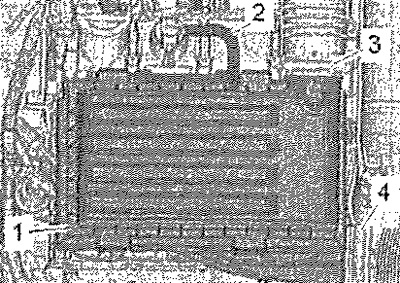

Detach air hose -2-. Remove air filter housing -1- from support pins towards top. Loosen clamps -3- and -4- and remove air pipe.

Note: For subsequent operations, use door trim removal tool -MP8-602/1- to release the retainers.

Disconnect upper connector -1- from engine control unit -J623-.

Note: On vehicles with engine control unit with protective cover, the protective cover must first be removed.

Remove connectors -2- and -3- from bracket and disconnect. Hang wires.

Disconnect connector -2-. Unscrew the pole protection -1- and disconnect the wire from the starter solenoid relay. Disconnect ground wire from body.

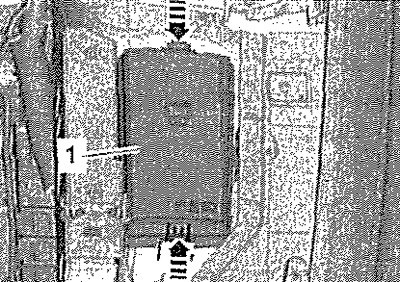

Unlock catches -arrows- and remove cover -1- for electronics box in engine compartment.

Unlock catch -arrow- with a screwdriver and remove cover -1- of electronics box in engine compartment towards top.

Loosen nut -arrow-, detach and hang out rein.

Disconnect connectors -1- and -2-.

For vehicles with manual gearbox

Disconnect the shift mechanism from the gearbox. Remove the slave cylinder.

For vehicles with automatic transmission

Remove the selector cable, disconnect the connector of the mechatronic unit and disconnect all brackets from the gearbox.

All

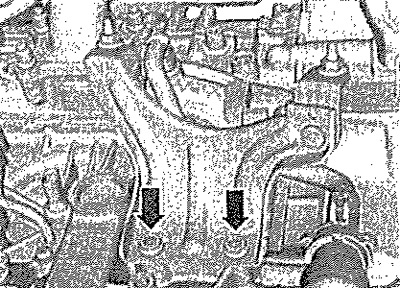

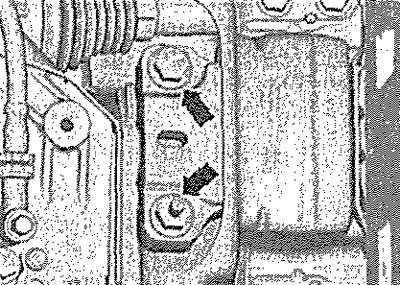

Loosen screws -arrows- for engine support by approx. 2 turns.

Unscrew bolts -arrows- for gearbox support by approx. 2 turns.

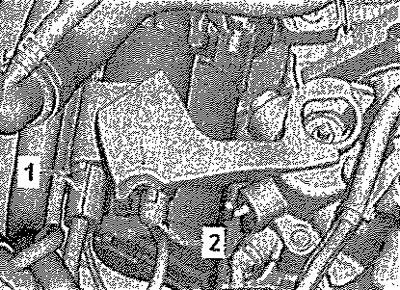

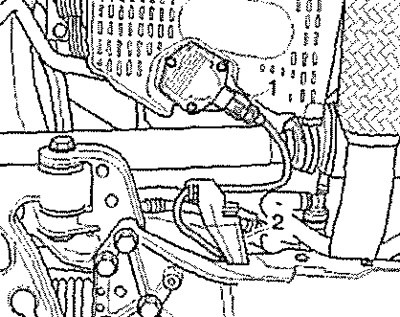

Disconnect electrical connector -1- from oil level and oil temperature sender G266-. Release wire from holder -2-.

Unscrew nuts -arrow- from stabilizer link on left and right.

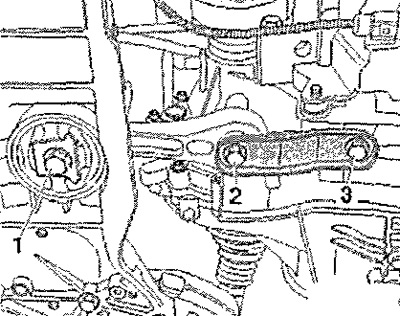

Loosen screws -1, 2, 3- and remove power unit bottom support.

Loosen screws -1- and remove heat shield for propshaft on right side, if present.

For vehicles with automatic transmission

Remove subframe. Disconnect the left and right drive shafts from the gearbox and tie up.

Instruction. Be careful not to damage the protective coating of the drive shaft. For vehicles with manual gearbox.

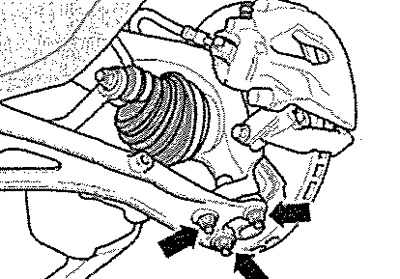

Unscrew nuts -arrows- on ball joints on left and right.

If a front left vehicle level sender -G78- is fitted, unscrew the nut -arrow- of the left suspension arm. Detach ball joints on left and right from control arms. Disconnect the left and right drive shafts from the gearbox and tie up.

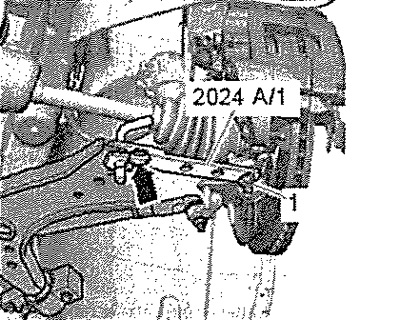

Pivot left shock absorber strut outward and support with extension -2024 A/1- as shown in illustration.

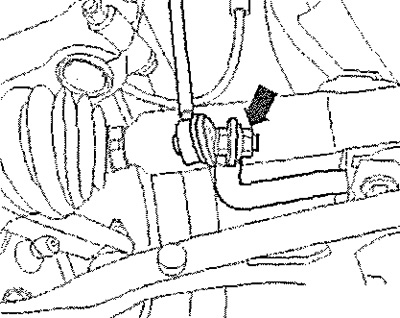

Attention! Risk of injury due to loose support parts. Secure retainer and ball joint with retainer -arrow- and nut -1-.

Attach right ball joint -2- to transverse link -1- with nut -arrow- as shown.

All

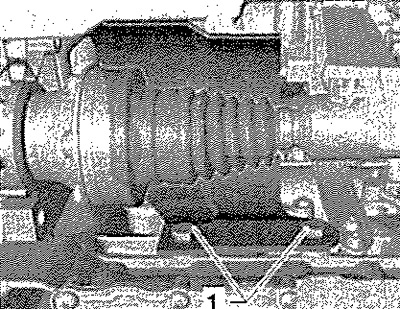

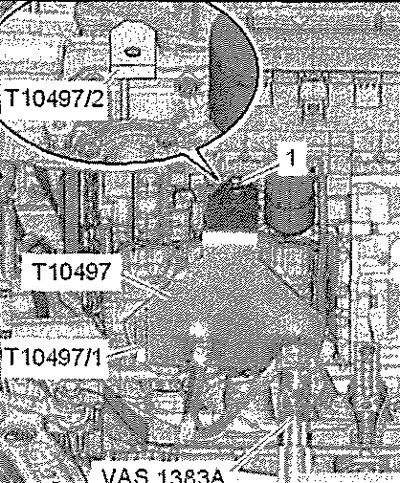

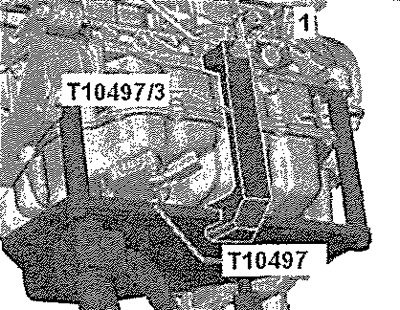

Install adapter T10497/2 on the rib of the cylinder block as shown in the figure. Position engine bracket T10497 with pins T10497/1 on cylinder block. Fasten adapter T10497/2 with screw -1- to engine support bracket T10497 and tighten to 20 Nm.

Fit adapter -T10497/3- to engine bracket -T10497- and tighten bolt -1- to 20 Nm. Attach engine and gearbox jack -VAG 1383 A- to engine support T10497 and raise power unit slightly.

Note: Unscrew the bolts of the power unit supports from the ladder, eg -VAS 5085-.

Completely unscrew bolts -arrows- for engine support. Completely unscrew screws -arrows- for gearbox support.

Carefully! Risk of damage to vacuum lines or electrical cables. Check that all vacuum lines and electrical wires connecting the engine, gearbox, subframe and body are disconnected. When lowering the power unit, remove it from the engine compartment with caution.

Slightly lower the power unit. Then turn the side of the gearbox of the power unit forward and only then slowly and carefully lower it. Disconnect the gearbox from the engine.