Note: If a large amount of metal chips and wear products are found in the engine oil during engine repairs, it is necessary to thoroughly clean the oil channels, oil nozzles and additionally replace the oil cooler, oil nozzles, and also the oil filter element to prevent secondary damage. The oil level must not exceed the max mark - risk of damage to the converter!

Check oil level, oil fill volume and oil specification.

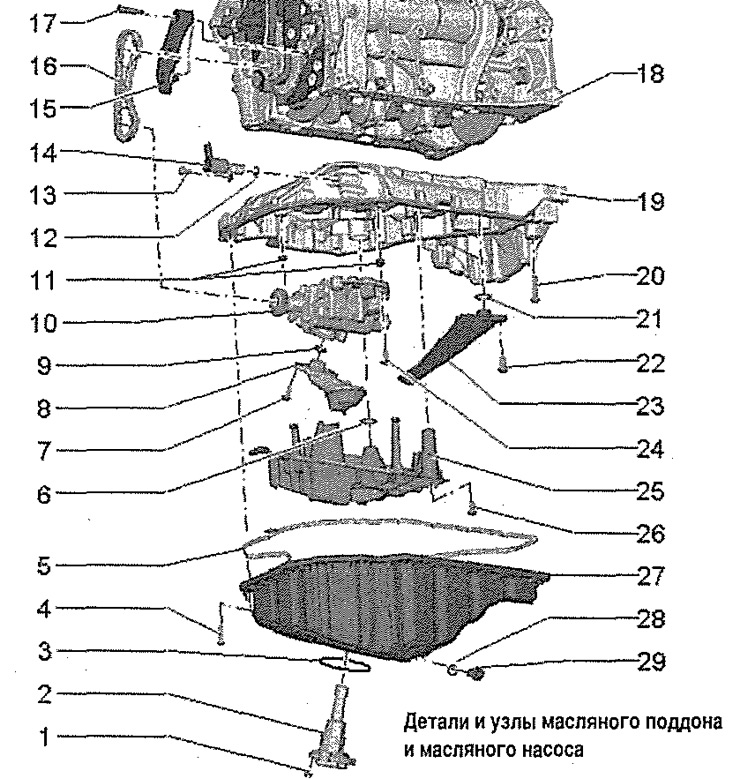

1. 9 Nm

2. Oil level and oil temperature sender -G266-

3. Gasket: replace

4. Bolt: replace

5. Gasket: Only for the bottom of the oil pan, stamped from a thin metal sheet

6. O-ring: replace; lubricate with engine oil

7. 4 Nm and tighten by 45° (1/8 vol.): replace

8. Inlet pipeline: clean the strainer in case of contamination

9. O-ring: replace; lubricate with engine oil

10. Oil pump

11. Centering sleeve

12. O-ring: replace; lubricate with engine oil

13. 4 Nm and tighten by 90° (¼ vol.): replace

14. Oil pressure control valve -N428-

15. Chain tensioner

16. Oil pump drive chain: mark direction of travel before removing

17.9 Nm

18. Cylinder block

19. Upper part of the oil pan

20. Bolt: replace

21. O-ring: replace; lubricate with engine oil

22. 4 Nm and tighten by 45° (1/8 vol.): replace

23. Oil return pipe

24. 8 Nm and tighten by 90° (¼ vol.): replace

25. Flow stop device: replace

26. 4 Nm and tighten by 45° (1/8 vol.): replace

27. Lower part of the oil pan

28. O-Ring or O-Ring: O-Ring - for lower part of oil pan only, stamped from thin metal sheet; o-ring - only for the lower part of the oil pan, made of plastic; replace; Moisten the O-ring with engine oil

29. Oil drain plug or plug: oil drain plug - only for the lower part of the oil pan, stamped from a thin metal sheet; tightening torque of the oil drain plug 30 Nm; plug - only for the lower part of the oil pan, made of plastic; tighten the oil drain plug until it stops