Carefully! Risk of damage to the clutch and other components. The engagement lever support and the entire release bearing assembly must be dry and free of oil and grease.

Remove the installed spherical pin with clip.

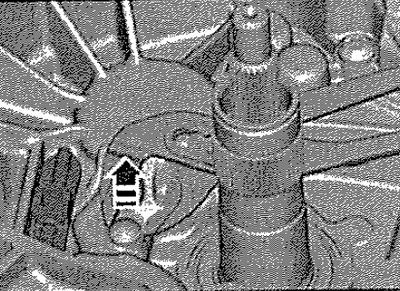

Install a new spherical pin.

Note: Press down on the spherical stud by hand, if necessary press in with a plastic mallet (do not damage the spherical pin).

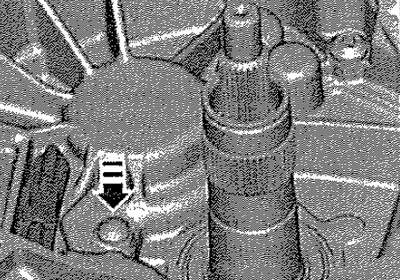

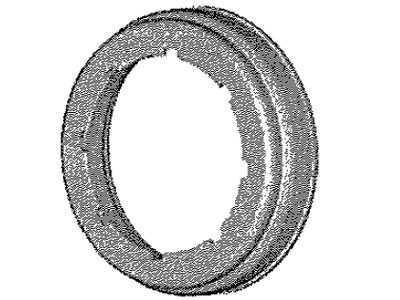

Install the old circlip of the outer input shaft - see arrow-.

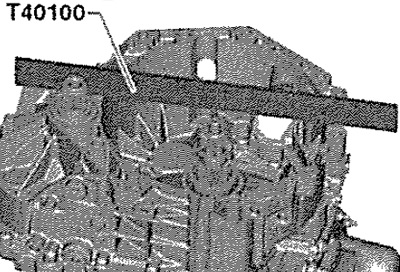

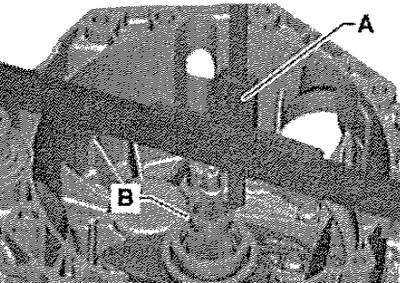

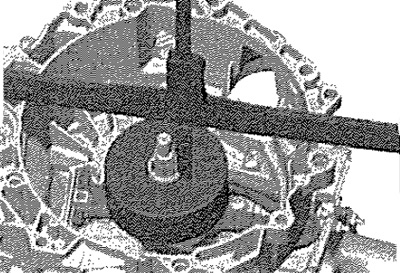

Lay straightedge -T40100- on upper edge of clutch housing flange.

Note: Ruler -T40100- must remain in this position. During all measurements, it is forbidden to shift or remove.

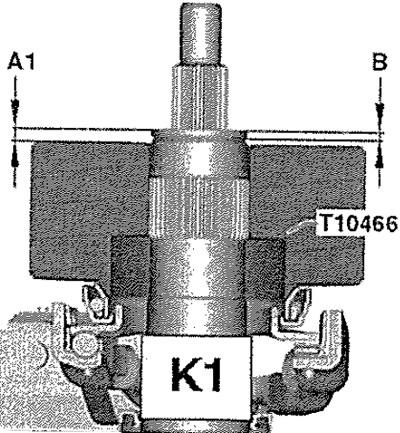

Fit digital depth gauge -A- to outer input shaft -B-. Reset depth gauge to '"zero".

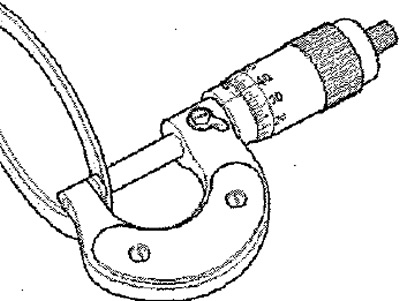

Measure the distance to the retaining ring. Record measurement result as "IN 1". Example: size "IN 1" = 2.62 mm.

measure size "IN" once again in a diametrically opposite place. Record measurement result as "AT 2". Example: size "AT 2" = 2.58 mm.

Note: Do not measure at the joint of the ring. In this case, you can move the ring from its place, and all measurement results will be incorrect.

Determine the average value of two measurements.

Example

Size "IN" \u003d B1 + B2 / 2 \u003d 2.62 + 2.58 / 2 \u003d 2.60 mm

This size "IN" required for subsequent calculations. In the following approximate calculation, the size is obtained "IN" = 2.60 mm. Size "IN" only in this example, for a different CP size "IN" will be different. Since there are 2 clutches, the adjustment is made in 2 stages. Each measurement requires different preparatory measures, as well as several pairs of calculations. Strictly adhere to the following order of work.

Remove the circlip again - see arrow-.

Note: This ring must not be installed again!

Determine the size "A1" shim large clutch engagement bearing "K1".

Attention! Do not install shim!

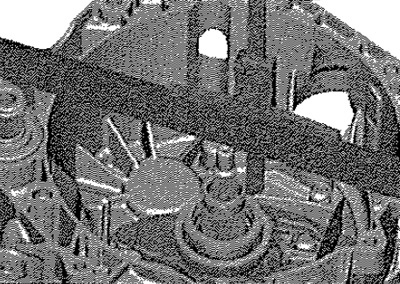

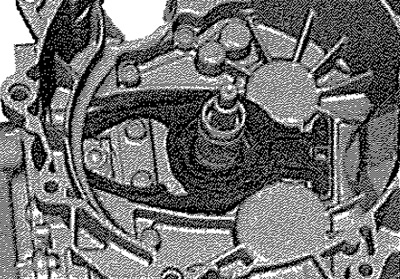

Install the large lever.

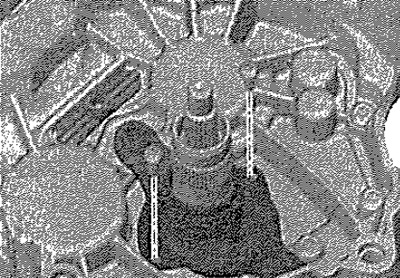

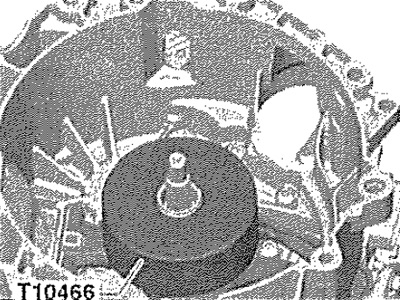

Install tip -T10466- on "big" engagement bearing. Press tip -T10466- once and turn. Observe how the engagement bearing rotates. Thus "sits down" tip -T10466- onto the bearing correctly.

Install digital depth gauge "above" on the outer input shaft and reset its readings to "0". Put the ruler -T40100t on "upper edge" clutch housing flange.

Measure distance to "shaft end" in tip -T10466-.

To make this measurement as accurate as possible, set the digital depth gauge twice, in diametrically opposite places. Thus, the most accurate value is determined, since minimizing unevenness "rocking" on the engagement bearing. Determine the average value from two measurements on the handpiece -T10466- average value "A1".

Record measurement result as "A1".

Example

Size "A1" = 4 93+4 91/2= 4.92 mm

Result: "A1" = 4.92 mm

Subsequent calculation

"A1" minus "IN" = depth of engagement bearing "KG.

Calculation example

4.92 mm minus 2.60 mm = 2.32 mm

Thus, the actual depth of seating of the engagement bearing in the gearbox is determined.

Continuation of the calculation

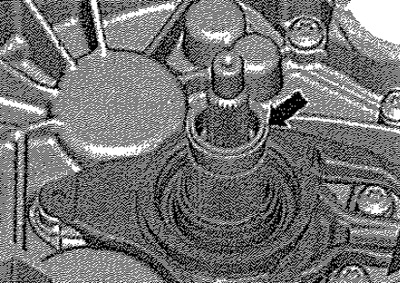

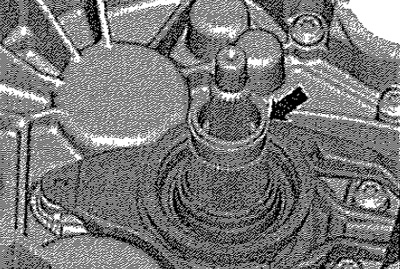

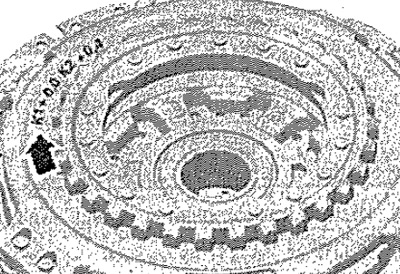

Now you can include the tolerances in the double disc clutch into the calculation. It's very simple: The tolerance value is indicated on "new" clutch -arrow-. This is usually a value between minus 0.40 and plus 0.40 mm, which is indicated on the new clutch. Write down the given value.

Example: K1 is marked on the clutch "+0.0 mm"

Last calculation for "K1": "Definite" gap plus clutch value = shim thickness "K1"

Calculation example

2.32 mm + 0.0 = 2.32 mm

Result: Shim thickness for "K1" = 2.32 mm

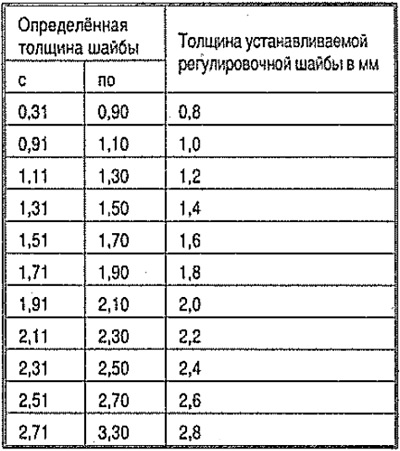

Select the correct washer from the table and set aside until installation.

Select the desired shim from the supplied shims and set aside until installation. In this case, a shim 2.30 mm, part number 0AM 141 383 D, is installed.

Attention! Then install only 1 of this shim. It is forbidden to install 2 washers.

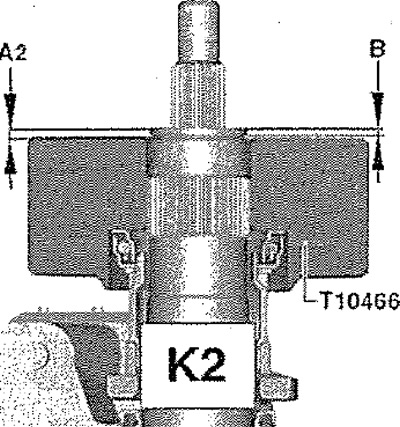

Thus, it is determined "correct" shim for "K1". When installing the clutch later, use only this shim. Continue clutch adjustment "K2". Determine the size "A2" adjusting washer of the small clutch engagement bearing "K2".

Remove the large lever.

Insert the small actuation lever with the upper and lower parts of the guide bush. Tighten the screws to the specified torque.

Install only the small bearing without the shim.

Attention! Do not install shim!

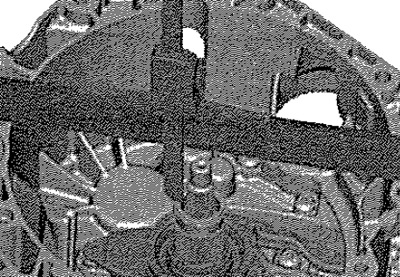

The small engagement bearing is mounted on 8 grooves in only one position. "crank", to make sure the small engagement bearing is seated correctly and the grooves are seated correctly.

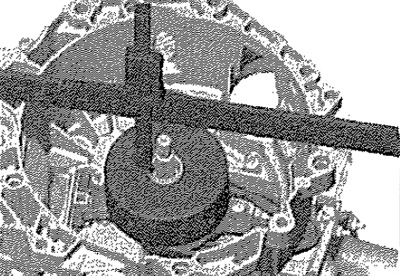

Position tip -T10466- on small selector bearing. Press tip -T10466- once and turn. Observe how the engagement bearing rotates. So 'sits down" tip -T10466- onto the bearing correctly.

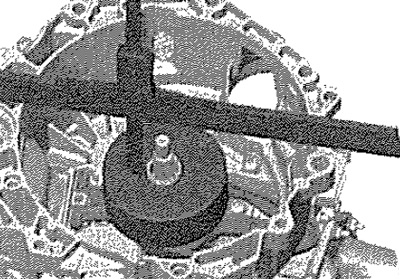

Install digital caliper "above" to the outer input shaft. Reset the depth gauge to "zero". Measure distance to "shaft end" in tip -T10466-. To make this measurement as accurate as possible, set the digital depth gauge twice, in diametrically opposite places. Thus, the most accurate value is determined, since minimizing unevenness "rocking" on the engagement bearing. Determine the average of the two measurements on the tip -T10466-. Record measurement result as "A2".

Example

Size "A2" = 4.79 + 4.75/2 = 4.77 mm Result: "A2" = 4.77 mm

Subsequent calculation

"A2" minus "IN" = depth of engagement bearing "K2".

Calculation example

4.77 mm minus 2.60 mm = 2.17 mm

Thus, the actual depth of seating of the engagement bearing in the gearbox is determined.

Continuation of the calculation

Now you can include the tolerances in the double disc clutch into the calculation. It's very simple:

The tolerance value is indicated on "new" clutch -arrow-.

This is usually a value between minus 0.40 and plus 0.40 mm, which is indicated on the new clutch. Write down the given value.

Example: K2 is marked on the clutch "+0.4 mm"

Last calculation for "K2": "Definite" gap plus clutch value = shim thickness "K2",

Calculation example

2.17 mm + 0.4 = 2.57 mm.

Result: Shim thickness for "K2" = 2.57 mm

Select the correct washer from the table and set aside until installation.

Thus, it is determined "correct" shim for "K2". When installing the clutch later, use only this shim. Select the required shim from the supplied shims and set aside until installation. In this case, a 2.60 mm shim is installed.

Attention! Then install only 1 of this shim. It is forbidden to install 2 washers.

Now you can install the clutch.