Attention! If the mechatronics breather is damaged during removal, it must be replaced. It is not possible to check the hydraulic oil level in the mechatronic circuit. Before installation work, the Mechatron/R unit vent must be plugged to prevent oil leakage. The oil level in the hydraulic circuit of the mechatronics is not monitored and spilled oil cannot be replaced. In the event of an oil leak, the mechatronic unit must be replaced!

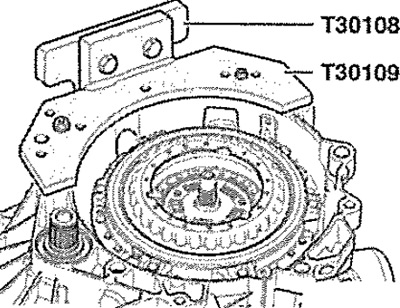

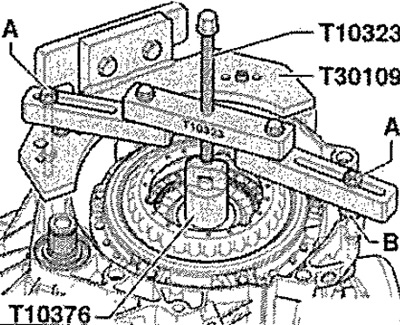

The gearbox with clutch must be mounted on the gearbox bracket -T30109 (VW 353) - upward movement. After moving and fixing the gearbox on the mounting stand, it must be inspected.

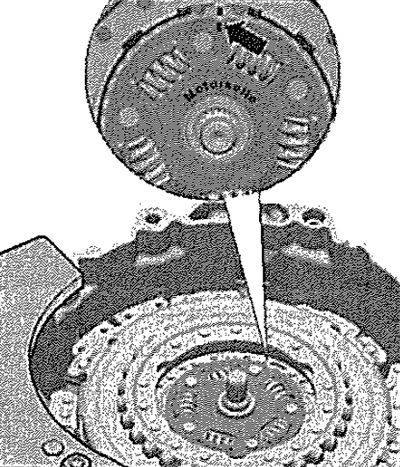

Note: Pull the clutch up. Mechatronics remains at the CP.

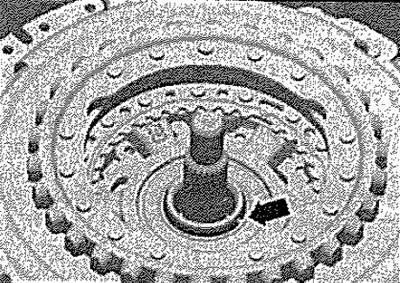

Remove the circlip of the disc hub - see arrow-.

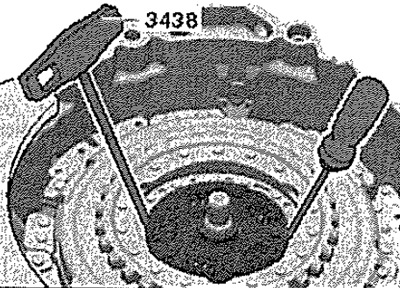

Remove wheel hub with hook -3438- and screwdriver.

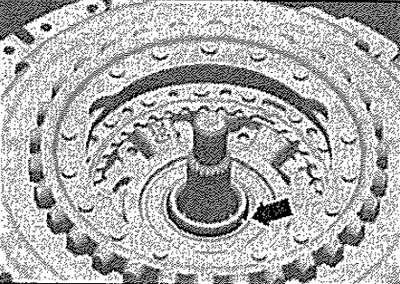

Remove the clutch retaining ring - see arrow-.

Note: It may happen that the clutch is so close to the circlip that the circlip "sits very tight". In this case, it is allowed to press the clutch down a little, as described in the following work order. Thus, the retaining ring is unloaded. Do not hit the clutch or shaft with a hammer! Always replace the circlip - see arrow-.

The circlip -arrow- of the clutch cannot be removed.

Note: If the circlip cannot be removed, press the clutch down slightly as described below.

Position support bar -T10323- parallel to clutch housing flange. Adjust distances, for example with washers -B- to a total thickness of 15 mm. Secure support bar -T10323- with screws -A- and nuts.

Carefully! Risk of damage to the clutch and other components! The clutch only needs to be pressed down slightly without much effort.

Gently press down the clutch on the spindle. Remove support bar -T10323-. Remove the clutch retaining ring - see arrow-.

Attention! The retaining ring must not be reused.

Continuation of work after removing the clutch retaining ring

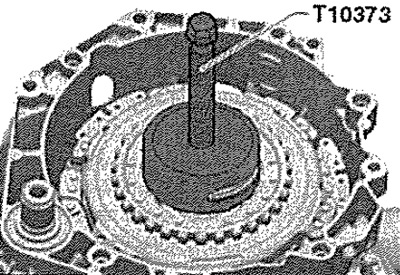

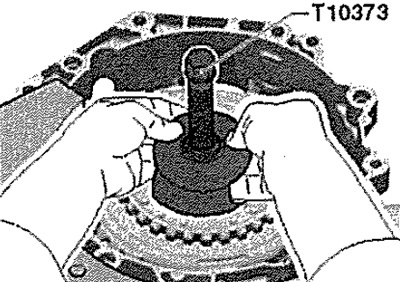

Insert puller -T10373- into clutch and remove clutch.

Remove clutch with puller -T10373-.

Remove the small engagement bearing.

Pull out the large lever.

Note: The upper part of the guide bush cannot be removed and installed separately. It is removed and installed only together with the lower part of the guide sleeve and the small release bearing.

Clutch release bearing adjustment "K1 and K2"

Attention. When replacing a double clutch, the following parts must be replaced at the same time: both engagement levers with release bearings, clutch lever spherical pin, release bearing shims. After replacing the double clutch and the indicated parts, it is necessary to re-adjust the position of the release bearings of the friction clutches "K1" And "K2". No adjustment is required if the above parts were simply removed and reinstalled. The circlip must be replaced in every case.

Install only the perfect tool. The clutch housing flange must be "absolutely smooth". Thus, a tight fit of the ruler is ensured. Mechatronic installed.

Short description

The position of the engagement support is related to the clearance between the bearing and the clutch release levers of the manual gearbox. The DSG gearbox has approvals for the gearbox engagement system and for the gearbox itself. Tolerances are also available inside the double clutch. When adjusting, these tolerances must be taken into account separately. The following procedure first of all shows how to determine all the required dimensions "by the CP", to install the correct shims. Tolerances on the gearbox side and tolerances in the clutch determine the thickness of the shim.