Carefully! Do not start the engine with the oil sump removed or without gear oil and do not tow the vehicle. Follow instructions for automatic transmission DSG - 0D9. Rules for cleanliness when working on the gearbox, especially with open mechatronics or transmission oil pump, contamination can lead to gearbox failure. Mechatronics is determined by the letter designation of the gearbox. Take into account the topic "contaminated oil", as well as instructions for changing the oil filter, When changing the transmission oil, it is not always necessary to change the transmission oil filter. Therefore, it is necessary to follow the instructions when to change the transmission oil filter and when not. When disconnecting and connecting the battery cable to ground, additional work must be performed. If the mechatronic is replaced with the gearbox removed, the gearbox must be mounted on a mounting stand.

Set the control lever to the VPH position, Disconnect the battery wire to ground with the ignition off. Remove the lower soundproofing casing of the engine. Remove the front left wheel arch cover. Drain coolant. Raise retaining clip -arrow- and detach lower left coolant hose from radiator.

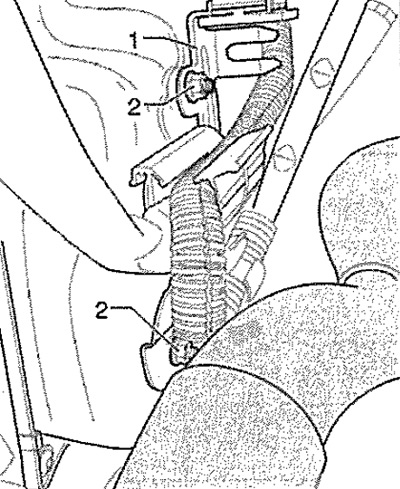

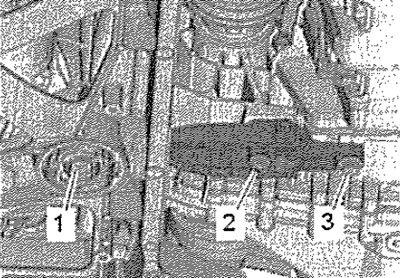

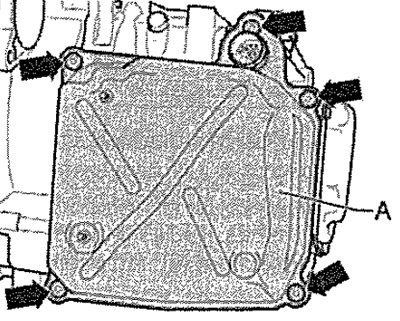

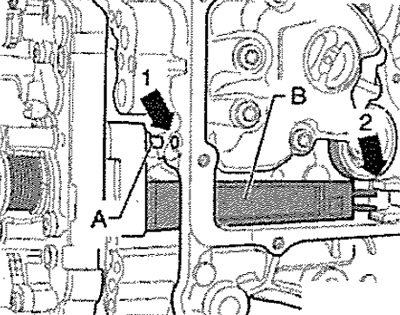

Remove the protective cover -A- from the underside of the gearbox - see. arrows-; in the presence of. Loosen the nuts -2- securing the holder -1- on the oil sump and remove the holder from the stud on the oil sump.

Note: The stud is welded to the oil sump at the front of the gearbox.

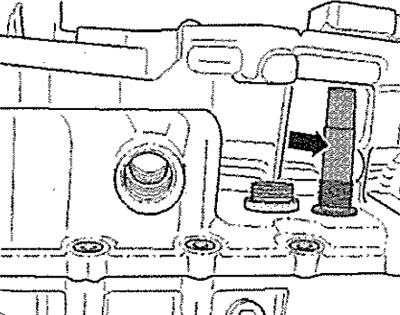

Take the pipes and wires in the area of the oil sump up and tie up. Install an oil collecting pan under the gearbox. Unscrew the level plug -see' arrow-.

Note: Behind this plug is a plastic overflow pipe, which can be tightened to 3 Nm with an 8 mm Allen key. The length of the overflow pipe determines the oil level in the gearbox, when replacing this pipe, observe the part number.

Remove overflow tube. Runs out approx. 5.0 liters of oil. Leave a pan to collect oil under the gearbox. Screw on the overflow pipe and tighten to the specified torque.

Remove the stabilizer bar support, to do this unscrew the screws -1, 2- and 3-. Then you can press the gearbox a little "back" to the attachment bracket, this will give you enough space to remove the mechatronics.

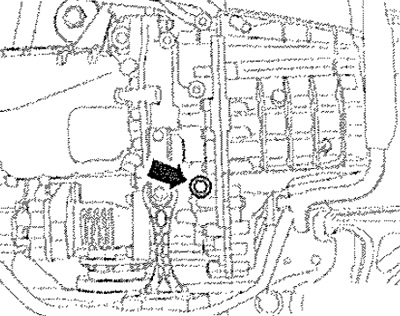

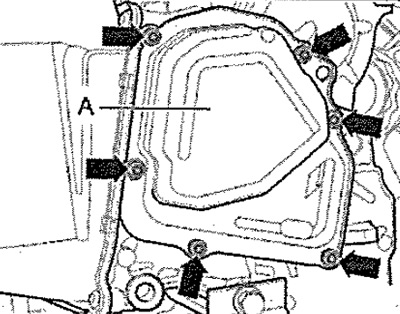

Loosen the screws - see arrows- and remove gear oil pump cover -A-. Touch your hand (without gloves) to ground to remove the electrostatic charge.

Carefully! The mechatronic unit for the dual-clutch gearbox -J743- may only be touched or touched after the electrostatic charge has been removed via a grounded object, eg the main ground contact. Never touch the plug-in contacts in the gearbox connector with your hands, so that a static discharge does not damage the control unit and mechatronics.

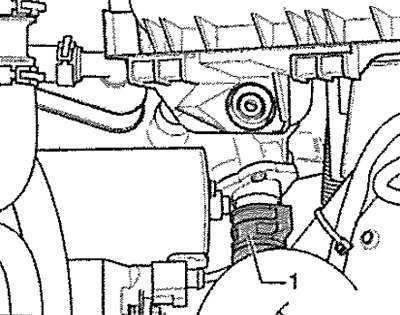

Unlock connector -1- for mechatronics by turning to the left and disconnect connector from gearbox.

screws - see Arrows - Loosen oil sump fasteners -A- and unscrew them in a cross pattern.

Note: There is still gear oil in the oil sump, as it cannot drain completely.

Remove oil pan with oil pan seal. Replace oil pan gasket. The gearbox oil pump cover and oil pan screws must be replaced.

Carefully! If the gear oil pump cover is not removed, the bracket for gearbox output speed senders -G195- and G1S6- on the reverse side can be damaged when the mechatronics unit for double clutch gearbox -J743- is removed.

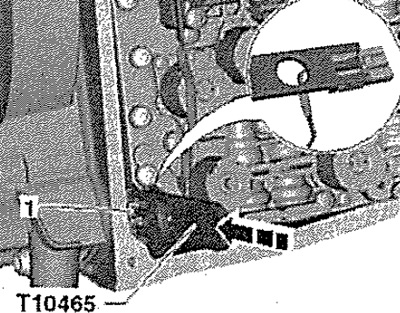

Unlock catch -1 - in -direction of arrow- with release tool -T10465- and remove carefully.

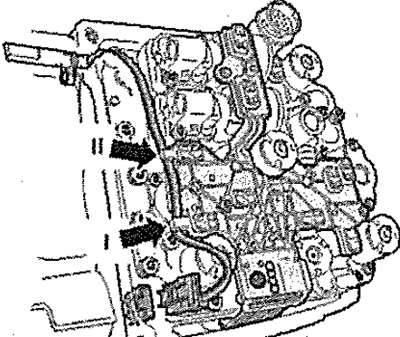

Release the wire from the retaining tabs - see. arrows, first from above, then from below.

Instruction. Do not pull on the wire! If the wire is damaged, the input shaft torque sender -C182-/clutch temperature sender -G509- must be replaced.

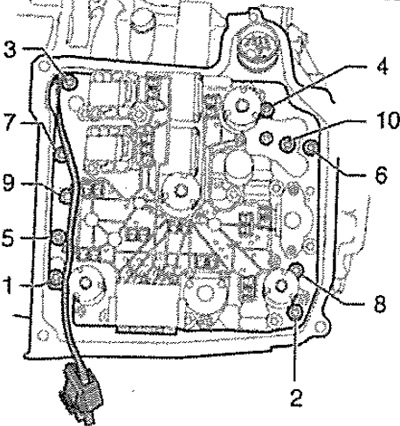

Loosen fixing screws -1- to -10- in sequence and remove.

Pull mechatronic unit out of gearbox housing until bracket for output torque senders -G195- and -G196- -B- on rear side comes out of gearbox housing. Carefully tilt down mechatronic for dual clutch gearbox -J743-.

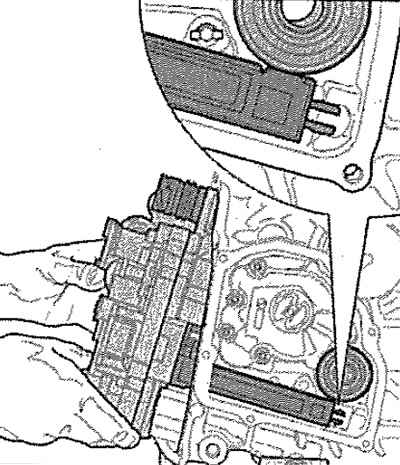

Pull out mechatronic unit for dual clutch gearbox -J743-.

Carefully! Never lift the mechatronic unit by the bracket for gearbox output speed senders -G195- and -G196- and place it on top of it.

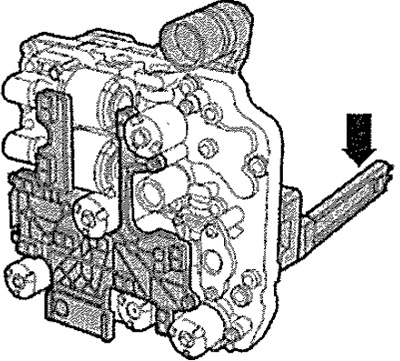

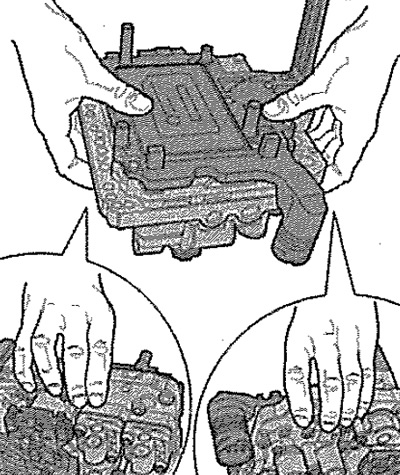

Transport and stow the mechatronics as shown in the figure.

When handling the mechatronics, pay particular attention to the long output shaft torque bracket -G195- and -0196- -see. arrow- (in case of damage "bracket" mechatronics needs to be replaced).