Note: All bandages loosened or cut during removal must be reattached to the same positions during installation. When disconnecting and connecting the battery cable to ground, additional work must be performed.

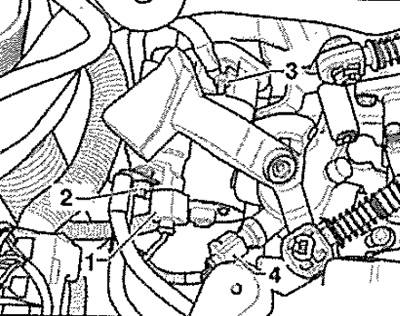

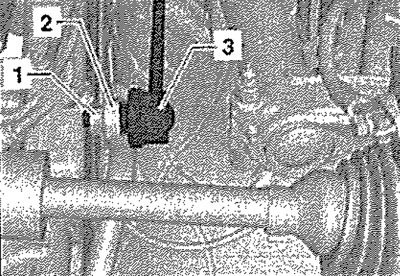

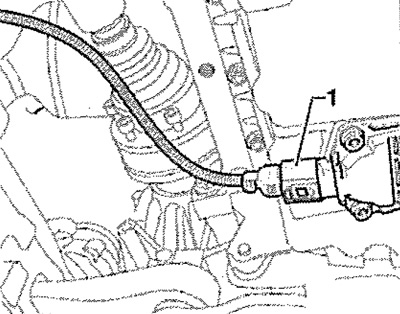

Disconnect the battery cable to ground with the ignition off. Remove battery and battery bracket. Remove the air filter if installed above the gearbox. Remove the water box cover. Disconnect connector -1- at starter motor and connector -4- at reversing light switch. Unscrew cable -2- on starter and ground wire -3-. Release wires. Loosen the top screws securing the starter.

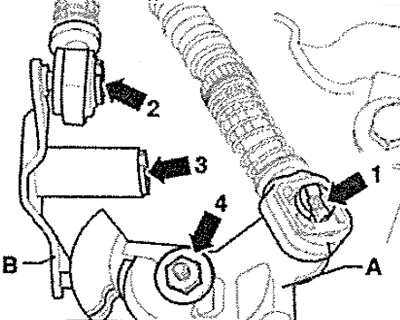

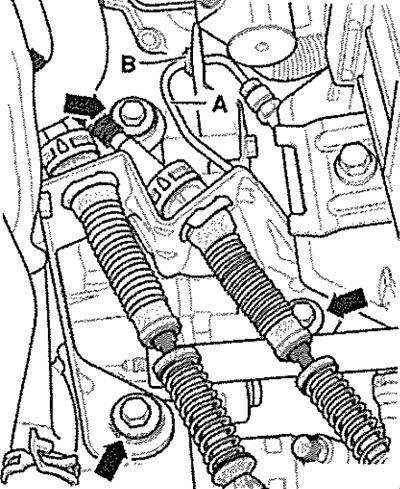

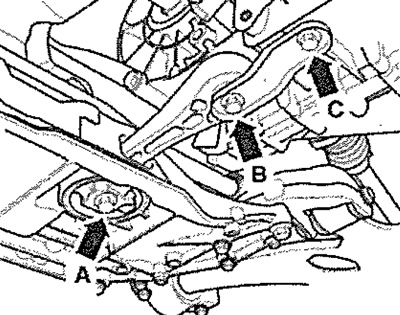

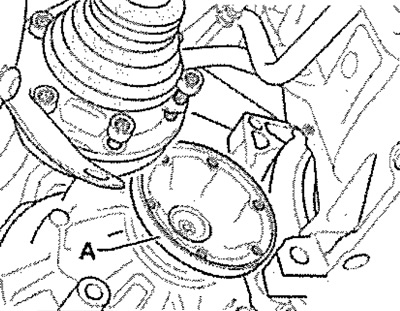

Remove the lock washer - see arrow 1 - gearshift cable from gearshift lever -A-. Remove the shift cable from the trunnion.

Metal lock lever

Remove the lock washer - see arrow 2- of the gear selector cable from the intermediate lever -B-. Remove the selector cable from the stud. Remove the lock washer - see arrow 3- off intermediate lever -B- and remove intermediate lever.

Note: The lock washers must always be replaced.

Intermediate lever made of plastic

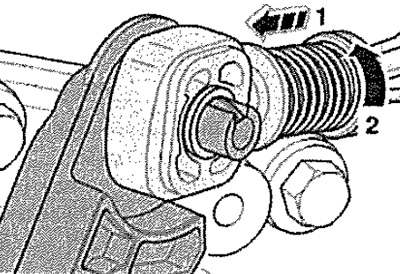

To prevent damage to the gear selection cable, it is necessary to separate the drive cable lock from the gear selection cable before removal. Pull the locking mechanism forward as far as it will go in -direction of arrow 1- and then lock it to the left in -direction of arrow 2-. Remove the intermediate lever together with the drive cable retainer.

Further for all vehicles

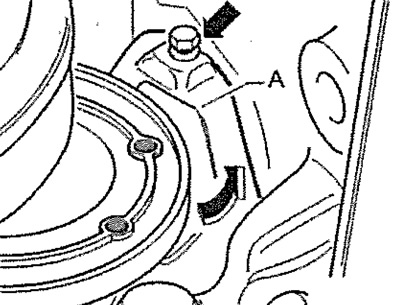

Remove gear lever -A-, to do this unscrew nut -see. arrow 4-.

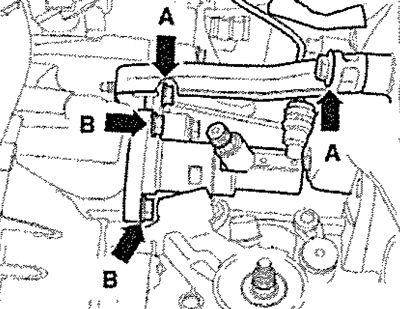

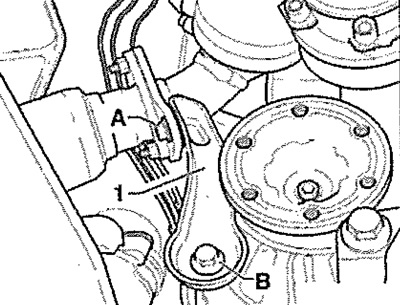

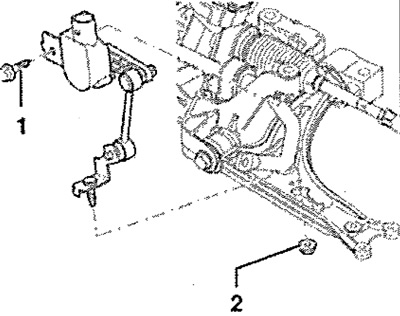

Remove drive cable counterholder from gearbox - see arrows - and tie together with the gear selection cable and the gear shift cable from the top side. Detach retainer -B- from gearbox and disconnect from hose line -A-.

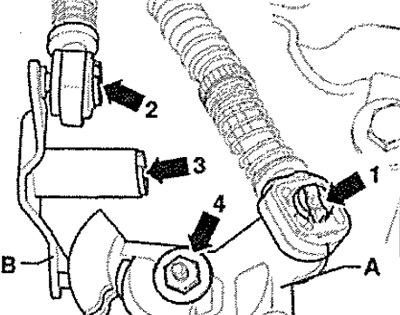

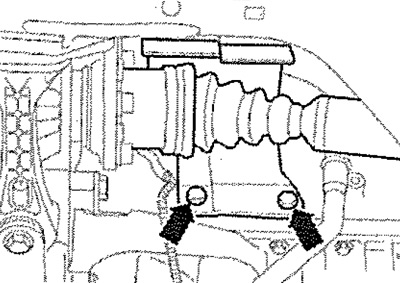

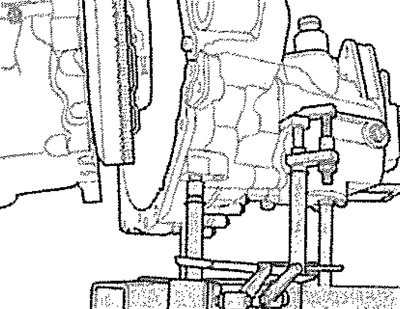

Remove support - see arrows A-. Remove slave cylinder - see arrows B- and set aside, secure with wire, do not open the piping system.

Attention! Do not depress the clutch pedal after removing the slave cylinder.

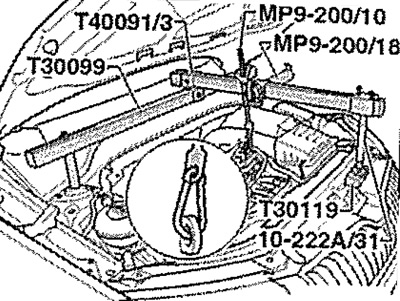

Loosen the left front wheel bolts. Unfasten upper engine/gearbox connecting screws. Fit retainer -T30099-.

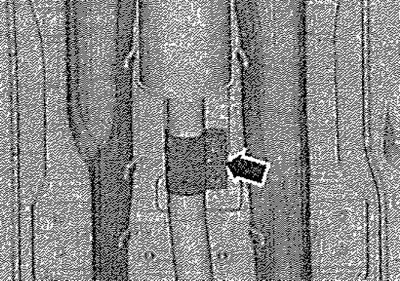

Unscrew nut -arrow- and remove earth wire from gearbox support.

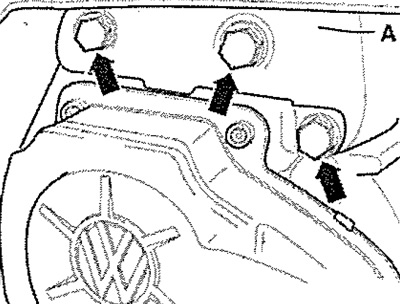

Slightly pull up the engine/gearbox assembly by the spindle. Loosen the fixing screws - see arrows - from the gearbox support.

Raise a / m. Remove the left front wheel. Raise the vehicle and remove the cover for the left front wheel arch. Remove starter. If present, remove the propeller shaft protection cap from the engine - see arrows-.

Unscrew bracket for exhaust pipe muffler - see. arrows-. Loosen clamping sleeve -arrow- and disconnect exhaust system.

Loosen nut -1- on stabilizer link -3- on both sides. Remove stabilizer link -3- from stabilizer bar -2- on both sides.

In the gearbox of vehicles with a start-stop system

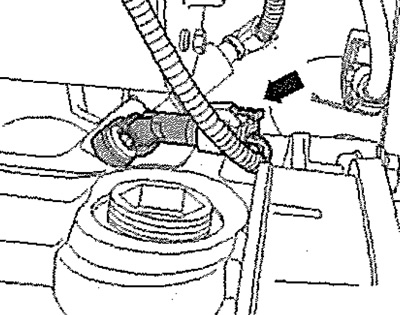

Unplug connector -arrow- at gearbox neutral position sender -G701-.

Further for all vehicles

Detach driveshafts from flanged shafts and tie up as high as possible (without damaging the protective coating). Disconnect connector -1- for oil level/temperature sensor (in the presence of).

Remove the stabilizer bar link - see arrows A, B- and -C-.

Remove the small protective shield -A- of the flywheel (in the presence of).

Release screws -A- and -B- and remove support -1- for exhaust manifold (in the presence of).

Disconnect the ride height sensor connector (in the presence of). Loosen nut -2-. Unscrew screw -1- and remove sensor.

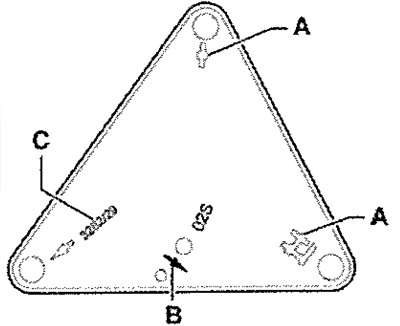

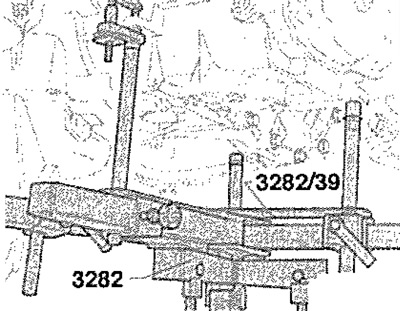

Insert gearbox support -3282- into engine and gearbox jack, eg -VAG 1383A-. Position gearbox support -3282- and adjustment plate -3282/39- on the engine/gearbox jack as follows; Place adjusting plate -3282/39- on gearbox mounting -3282- (adjusting plate rises in only one position). Align the gearbox mounting brackets in accordance with the holes in the adjustment plate. Screw in fasteners -A- and -C- as shown on the adjustment plate. Position engine/gearbox jack under vehicle, arrow -B- on adjustment plate points in direction of travel/vehicle.

Fasten the adjusting plate parallel to the gearbox and to the brackets on the gearbox. Carefully lower the engine with gearbox slightly.

Note: Pay attention to all pipes when lowering the gearbox.

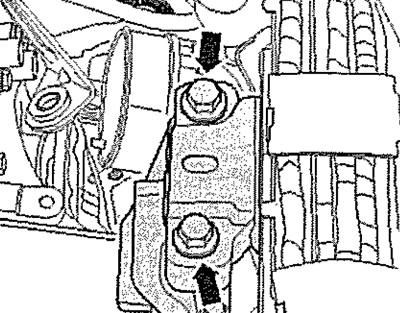

Remove gearbox console -A- -see arrows-. Unscrew the lower engine/gearbox connecting screws.

Note: Unscrew the connecting screw above the flanged shaft, if present.

Squeeze out the gearbox from the unloading sleeves. Slightly push the engine forward. Turn gearbox down and back at gearbox mounting spindles -3282-.

Carefully lower the gearbox while passing the right-hand flange shaft -A- as shown, in the area of the flywheel/intermediate plate. Change gearbox position when lowering using gearbox mounting spindles -3282-.

Note: Pay attention to all pipes when lowering the gearbox.