- Drill ∅ 3 mm (standard type).

- Drill ∅ 6 mm (standard type).

- Protective glasses (standard type).

- Receiving vessel for collecting oil (standard type).

- Pipe cutter, eg. Stahlwille Express -150/3- (standard type).

Note. There are two possibilities for eliminating shock absorbers.

Removal of gas from the front and rear gas-filled shock absorbers

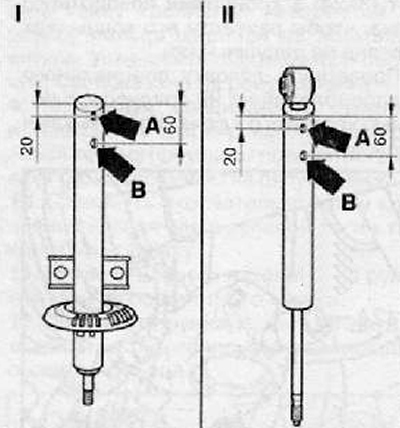

Option A: Gas removal by drilling.

- I - Gas-filled shock absorber, front

- II - Gas-filled shock absorber, rear

Clamp the gas-filled shock absorber in a vertical position in a vise so that the piston points downwards.

Attention. Safety goggles must be worn while drilling.

Drill a ∅ 3 mm hole -arrow A- in the outer tube of the shock absorber.

Note. When drilling, gas leaks.

Continue drilling until the shock absorber inner tube is also drilled (depth approx. 25 mm).

Drill a second hole ∅ 6 mm -arrow B- into the outer and inner tubes of the shock absorber.

While holding the shock absorber over the oil trapping bath, move the piston rod back and forth several times over the entire stroke length until the oil leakage stops completely.

Removal of gas from the front and rear gas-filled shock absorbers

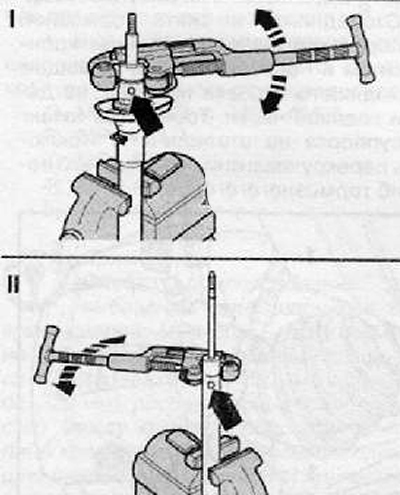

Option B: Opening with a pipe cutter.

- I - Gas-filled shock absorber, front

- II - Gas-filled shock absorber, rear

Clamp the gas-filled shock absorber in a vertical position in a vise so that the piston points upwards.

Attention. Safety goggles must be worn while drilling.

Drill a ∅ 3 mm hole -arrow- in the outer tube of the shock absorber.

Note. When drilling, gas leaks.

By installing a pipe cutter, for example. Stahlwille Express 150/3-, according to the drawing, separate the outer tube of the shock absorber.

Pull the piston rod up while holding the inner tube with a pipe wrench and pushing it down so that it stays in the outer tube when the piston rod is slowly pulled out.

Pull the piston rod out of the piston tube.

Empty the shock absorber tube.