Note.

- Necessary devices, special control and measuring devices, as well as auxiliary means:

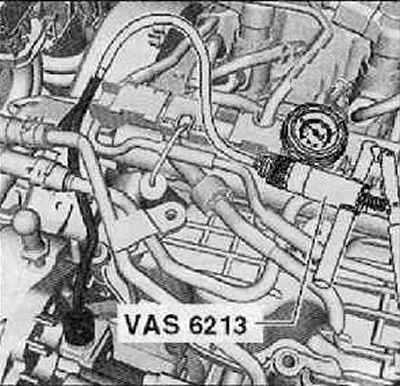

- Manual vacuum pump, e.g. -VAS 6213-.

- Make an -adapter- from the high pressure fuel line.

Condition for exercising control

Inspection of the low pressure side of the fuel line was carried out but did not result in a complaint.

The reverse quantity on the high pressure pump was checked but did not result in any complaints.

The fuel tank is filled with clean fuel in accordance with current regulations.

The starter rotates at starting speeds > 230 rpm.

Work progress

Note. When working on the power supply system, safety precautions must be observed.

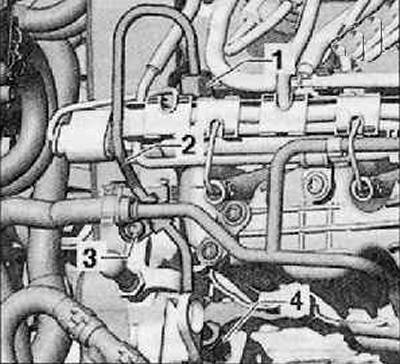

1. Remove the high pressure line -2- between the fuel distributor and the high pressure pump, pos. 12.

2. Connect the prepared, well-cleaned adapter to the high-pressure neck of the high-pressure pump with a tightening torque of 20 Nm.

3. Connect hand vacuum pump -VAS 6213- to additional adapter.

4. Use the hand vacuum pump -VAS 6213- to pressurize to min. 1 bar.

If the high pressure pump is OK, the pressure will remain constant for more than 30 seconds.

If the high pressure pump is faulty, the pressure will drop within 2 seconds. 3 s back to 0 bar.

If necessary, repeat the test, observe the decrease in pressure of the hand vacuum pump -VAS 6213-.

5. Replace high pressure pump.