Note.

- When working on the power supply system, safety precautions must be observed.

- When working on the power supply system, cleanliness rules must be observed.

Note.

- Necessary special devices, control and measuring devices, as well as auxiliary means:

- Tool kit -T10133-.

Replacing the Teflon O-Ring

1. Remove the fuel injectors.

2. Thoroughly clean the fuel injector.

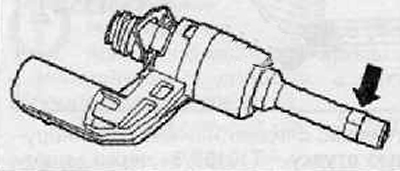

3. Carefully cut the O-ring with a knife as shown (arrow). Prevent the knife blade from touching the valve body.

4. Removing the old O-ring. clean the groove where the O-ring is installed (arrow), as shown in the figure below. deposits (soot) should be removed with a brass brush.

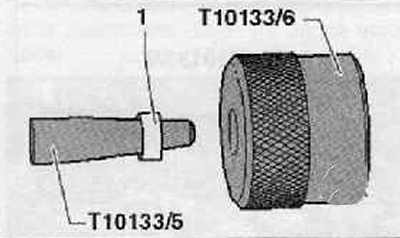

5. Put on a new O-ring (1) assembly cone -T10133/5- shown in the figure below. Move sealing ring slightly with assembly sleeve -T10133/6- (corrugated - to the sealing ring (1)), as far as possible on the assembly cone -T10133/5-.

6. Assembly sleeve -T10133/6- must be turned (the knurling is no longer directed towards the O-ring) and put on the o-ring (1) assembly cone -T10133/5-.

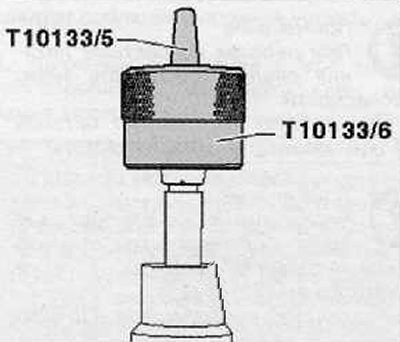

7. Now push assembly cone -T10133/5- with O-ring onto fuel injector from the front. Push O-ring with assembly sleeve -T10133/6- further onto fuel injector.

The sealing ring is not yet seated in the groove.

8. Remove assembly sleeve -T10133/6- and assembly cone -T10133/5- as shown in the figure below.

9. Insert the O-ring into the groove by hand.

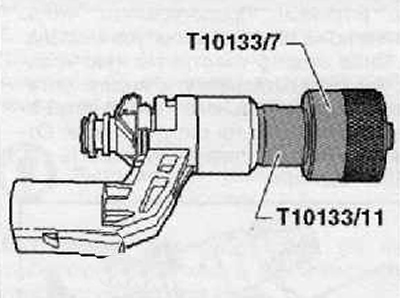

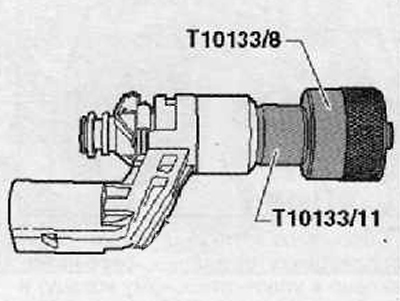

10. Install spacer sleeve -T10133/11- on valve body.

11. Press the sizing sleeve -T10133/7- through the O-ring until it stops against the spacer sleeve -T10133/11- as shown in the figure below.

12. Remove the sizing sleeve -T10133/7- shown in the figure below.

13. Now press the sizing sleeve -T10133/8- through the O-ring until it stops against the spacer sleeve -T10133/11-.

14. Remove calibration sleeve -T10133/8- again.

Note. The Teflon O-ring now has the correct installation size.

Support ring replacement

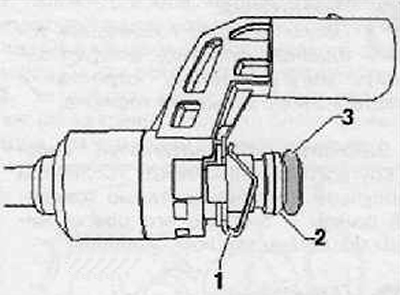

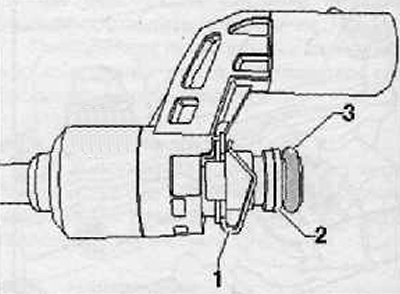

1. Remove the O-ring (3), shown in the figure below.

2. Cutting the support ring (2) small side cutter, remove it as shown in the figure below.

3. Having removed the elastic part from the fuel injector (1), install lock washer -T10133/12- instead.

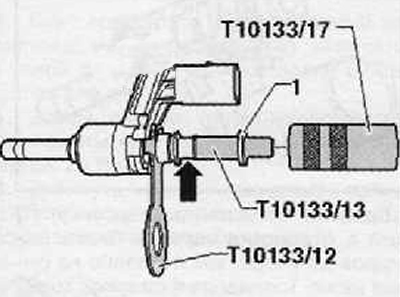

4. Putting on a new support ring (1) on the assembly cone -T10133/13-, install the latter on the fuel injector as shown in the figure below.

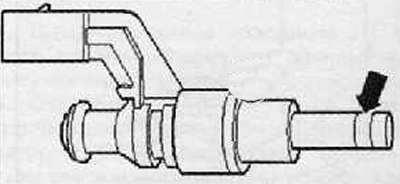

5. Insert support ring (1) sizing sleeve -T10133/17- (corrugated side - to the fuel injector) on the fuel injector up to the first groove (arrow), as shown in the figure below.

Note. Now turn the calibration sleeve -T10133/17 - (knurled side is no longer directed towards the fuel injector).

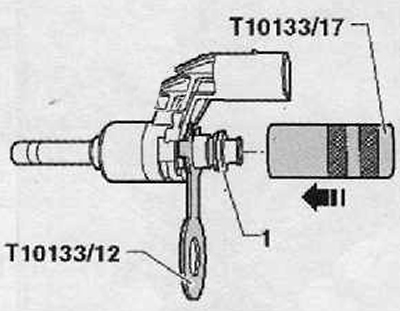

6. Push the calibration sleeve through the support ring (1) in the direction of the arrow until it stops against the lock washer -T10133/12- as shown in the figure below.

7. Remove calibration sleeve -T10133/17- again.

Note. The support ring now has the correct assembly size.

8. Now it is necessary to install instead of the lock washer -T10133 / 12 - a new elastic part (1) and install a new O-ring (3) in front of the support ring (2), as shown in the figure below.

Note. Teflon sealing ring (arrow) do not lubricate with oil to install the fuel injector.

9. Install fuel injectors.

10. Further installation is carried out in the reverse order of removal.