Removing

Attention.

- For any assembly work, especially in the engine compartment due to the narrow assembly area, the following instructions must be observed:

- Any kind of pipeline (e.g. for fuel, hydraulic system, coolant, brake fluid, vacuum lines) and electrical wires should be laid in such a way as to restore their original condition.

- Ensure that there is sufficient space between the piping and moving or hot components to avoid damaging the piping.

1. With the ignition off, disconnect the negative terminal from the battery.

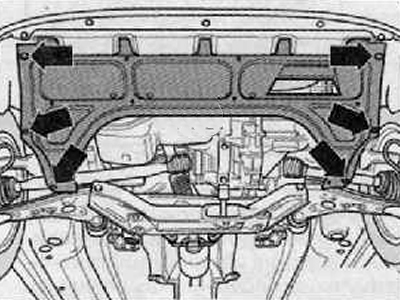

2. Remove the lower protective casing of the engine compartment (arrows), as shown in the figure below.

3. Unscrew the mounting bolts and disconnect the right and left drive shafts from the gearbox (for details, see the relevant section in chapter Drive shafts).

4. Raise the drive shafts and tie them down using a suitable piece of wire.

5. Remove the front of the exhaust pipe (for details, see the relevant section in chapter Intake and exhaust system).

6. Drain the coolant into a prepared container.

7. Remove the battery and battery holder (for details, see the relevant section in chapter Engine electrical equipment).

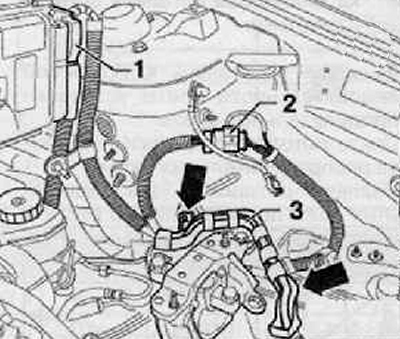

8. Disconnect the wiring harness connector (1) from the engine control unit, as shown in the figure below.

9. Disconnect the wiring harness connector (2), shown in the figure below.

10. Release the wire holder from the fixed position (3) (arrows), as shown in the figure below.

11. Disconnect all wires from the engine, transmission, starter and radiator that would interfere with removal.

12. Remove the intake hose from the vacuum brake booster.

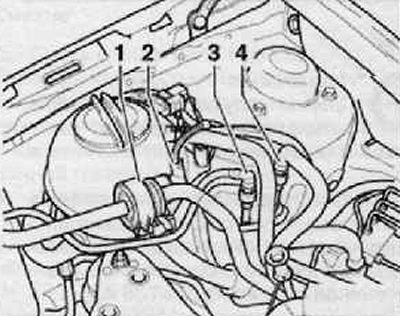

13. Having pressed the buttons of the latches, disconnect the fuel supply (4) and drain (3) power system connections as shown in the figure below.

14. Disconnect the wiring harness connector (2), then disconnect and remove the solenoid valve of the activated carbon tank, fuel vapor recovery system (1), as shown in the figure below.

15. To remove a hose for removal of air from system of cooling from a forward tube for a cooling liquid.

16. To remove a water hose of system of cooling from a branch pipe under a broad tank of system of cooling.

17. Remove the counter support of the flexible shafts (Bowden cables).

18. Remove the hydraulic clutch release cylinder (for details, see the relevant section in chapter Manual Transmission).

19. Disconnect the coolant hoses at the top and bottom - on the connecting pipes from the radiator.

20. Unscrew the fastening bolts (arrows) and remove the oscillating support of the power unit.

For vehicles with air conditioning

Attention. Do not open the refrigerant circuit of the air conditioning system.

21. Remove the V-ribbed implement drive belt (for details, see the relevant section in this chapter).

22. Disconnect the wiring harness connector from the A/C compressor.

23. Remove the A/C compressor with attached piping.

24. Suspend the air conditioning compressor from the vehicle in such a way that no collision occurs during the removal of the unit from the vehicle.

Note. Do not bend the pipes of the air conditioning system connected to the compressor.

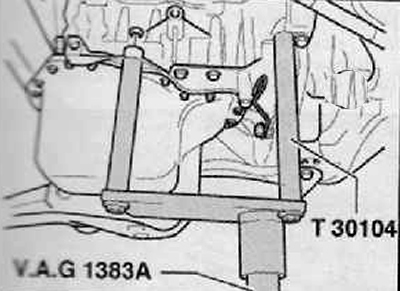

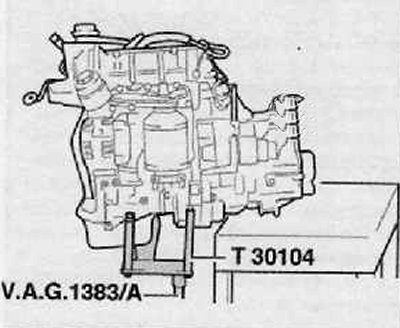

25. Install bracket for engine support -T30104- in tool for removing and installing power unit, eg -VAG 1383/A-.

26. Attach engine support bracket -T30104- with lock nuts and M8 screws applying a tightening torque of 30 Nm to the cylinder block.

Note.

- Check that all hose and proxy connections are disconnected:; between the engine, gearbox and body and, if necessary, disconnect them.

- Use the ladder -VAS 5085- to remove the fixing bolts.

27. Slightly raise the engine with gearbox using a device for removing and installing the power unit, e.g. -VA G 1383/A-.

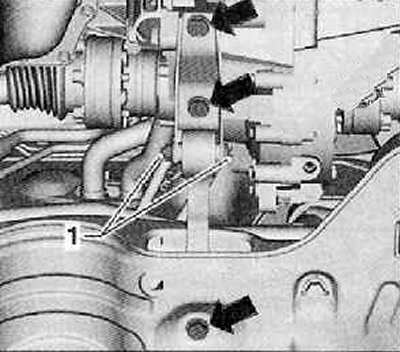

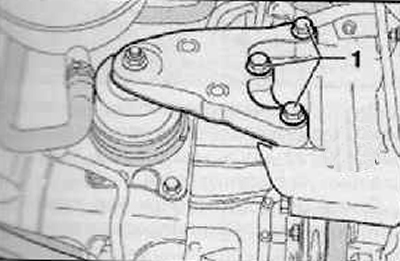

28. Unscrew the fastening screws (1), shown in the figure below.

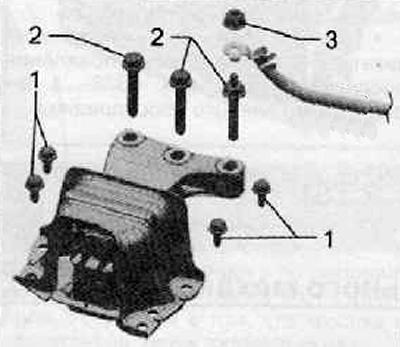

For vehicles with other support type

29. Loosen the fastening nut (3) and disconnect the wire from the bracket «masses», shown in the figure below.

30. Unscrew the bolts securing the bracket to the support of the power unit (2), as shown in the figure below.

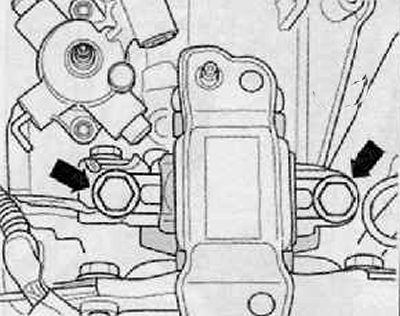

31. Unscrew the fastening screws (arrows) from the gearbox bearing.

32. Lower the engine with the gearbox down.

Note. When lowering the engine with the gearbox, you need to do it carefully. It is necessary that there is always enough space in the surrounding space.

Mounting the engine on the assembly stand

33. Place the engine and gearbox with the tool for removal and installation to the table for putting things away.

34. Lower the engine with gearbox so that the gearbox rests on the table top.

35. Unscrew the bolts connecting the engine and gearbox.

36. Disconnect the gearbox from the engine.

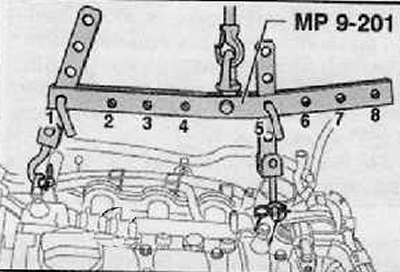

37. Hooking a hanging device (MP9-201 (2024 A)) in the manner indicated below, lift with a workshop crane from the support of the power unit.

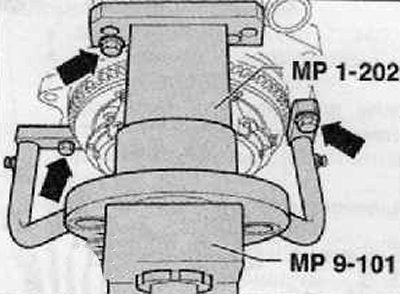

38. For assembly work, it is necessary to fix the engine with a device for removing and installing the engine and gearbox (MP1 202) (with 3 bolts (arrows)) on the assembly stand -MP9-101- as shown in the figure below.

Installation

1. Installation is made in reverse order to removal. Observe the following instructions:

- Check the presence in the cylinder block of 2 centering bushes for centering the gearbox, if necessary, insert them.

- If necessary, check the correct centering of the clutch disc.

- Check the clutch release bearing for wear and, if necessary, replace the bearing.

- Lubricate spline connection on drive shaft with grease -G 000 100-.

- When assembling the engine-gearbox assembly, make sure that there is enough free space left in relation to the rest of the parts.

- Align the engine with the gearbox in such a way that there are no internal stresses.

- Install the hydraulic clutch release cylinder (for details, see the relevant section in chapter Manual Transmission).

- Connect shift actuator and adjust bowden cables for shifting.

For vehicles with air conditioning

- Install air conditioning compressor (for details, see the relevant section in chapter Heating, ventilation and air conditioning system).

- Install the V-ribbed implement drive belt (more, see relevant section in this chapter).

Continuation for all cars

- Connect the right and left drive shafts to the gearbox.

- Install the front section of the exhaust pipe, align the exhaust system without internal stresses.

- Connect coolant hoses.

Note. Drained coolant can only be used if the engine block, cylinder head, radiator or heat exchanger has not been replaced.

- Pour coolant.

- Before starting the engine, check the oil level.

- Adapt engine control unit to throttle valve control unit -J338- using special tool.

Note.

- Before proceeding with installation, lubricate all bearings and working surfaces with oil.

- If, during engine repair, metal chips or abraded particles of material appear in an increased amount, this may indicate damage to the main bearings of the crankshaft or connecting rod bearings. To eliminate the occurrence of subsequent damage, the following work must be performed after repair.

- Clean the lubrication channels thoroughly.

- Replace oil injection nozzles.

- Replace oil cooler.

- Replace oil filter.