Removing

Note.

- The engine is removed together with the gearbox downwards.

- All cable clamps (bandages), which were loosened or cut during the removal of the engine, must be reattached in the same place when reinstalling the engine.

- The key must be left in the ignition to prevent the steering wheel from locking.

- The drained coolant must be diverted into a clean container for subsequent use or disposal.

Attention.

- For any assembly work, especially in the engine compartment due to the narrow assembly area, the following instructions must be observed:

- Any kind of pipeline (e.g. for fuel, hydraulic system, coolant, brake fluid, vacuum lines) and electrical wires should be laid in such a way as to restore their original condition.

- Ensure that there is sufficient space between the piping and moving or hot components to avoid damaging the piping.

- Reduce the pressure in the high pressure part of the supply system.

1. Before disconnecting the battery, any adapter for the anti-theft wheel bolts must be removed from the trunk.

2. Remove the battery (for details, see the corresponding section in the chapter Engine electrical equipment).

3. Remove the air filter assembly (for details, see the relevant section in chapter Intake and exhaust system).

4. Remove the battery holder (for details, see the relevant section in chapter Engine electrical equipment).

5. Remove the fenders of the right and left front wheel arches (for details, see the relevant section in chapter Body).

6. Remove the lower protective casing of the engine compartment.

7. Drain the coolant into a prepared container.

8. Disconnect the right drive shaft (for details, see the relevant section in chapter Drive shafts).

9. Unscrew the mounting bolts and disconnect the left drive shaft from the gearbox flange (for details, see the relevant section in chapter Drive shafts).

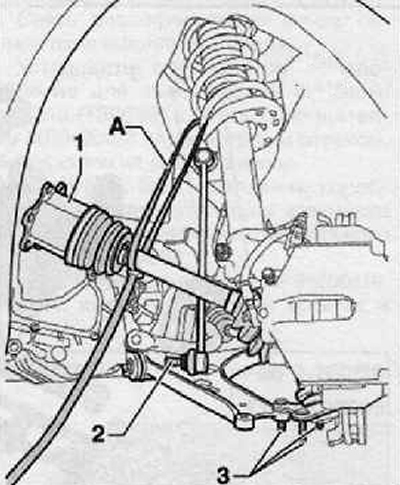

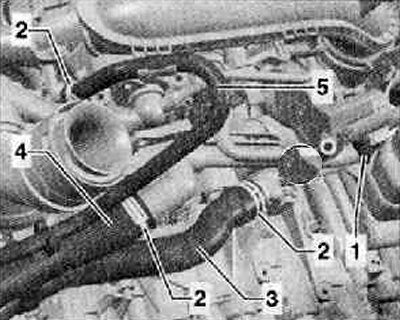

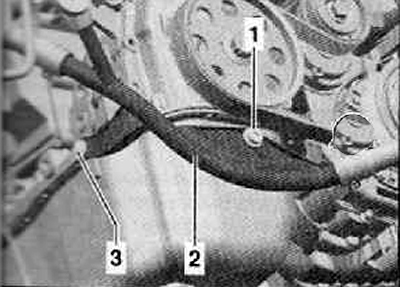

10. Unscrew the nut securing the left strut of the anti-roll bar (2), as shown in the figure below. Pull the stabilizer link away from the anti-roll bar.

11. Unscrew the nuts securing the lower arm of the front suspension to the ball joint (3), as shown in the figure below.

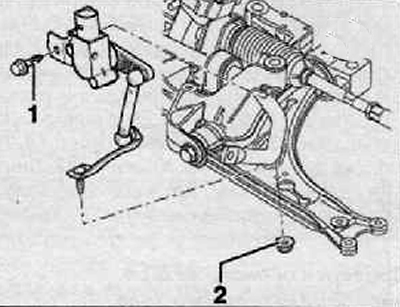

12. If a vehicle level sensor is installed, it is necessary to unscrew the fastening nut (2) and disconnect the sensor strut from the left front suspension arm.

13. Turn the steering wheel all the way to the left.

14. Move the steering knuckle outward, fix the drive shaft (1) with tape (A) in the wheel arch as shown in the picture above.

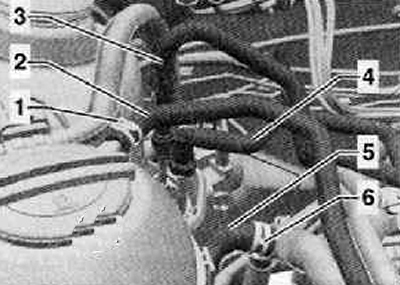

15. Disconnect coolant hoses (2) And (5), as shown in the figure below.

16. Disconnect the fuel line (the retaining ring must be pressed in upwards) (3) And (4); as shown in the picture below. Escaping fuel should be removed with a rag.

17. Loosen the coolant hose clamp (3), shown in the figure below.

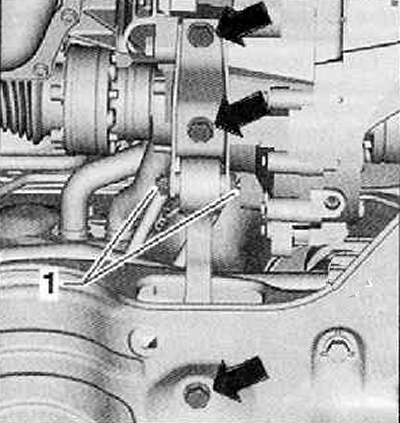

18. Release clamp (1), disconnect the coolant hose (2) from the engine, as shown in the figure below.

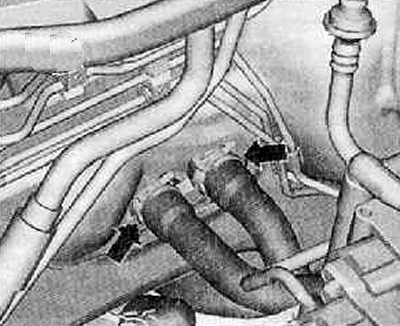

19. Disconnect the heater hoses shown in the figure below (arrows).

20. Disconnect intake hose (1) from the intake manifold as shown in the figure below.

21. Loosen the clamps (2), disconnect the coolant hoses (3...5), as shown in the figure below.

For vehicles with automatic transmission

22. To take fastening of a cable of a choice of an automatic mode of operation from a transmission.

For vehicles with manual transmission

23. To remove a drive of a gear change from a transmission.

24. Remove the hydraulic clutch release from the gearbox (for details, see the relevant section in the chapter Manual transmission).

Attention. After removing the slave cylinder of the clutch release actuator or disconnecting the hydraulic system wires, do not press the clutch pedal again.

Continuation for all cars

25. Disconnect all electrical wires from the gearbox, alternator and starter, catch them to the side.

26. Disconnect all other necessary wires from the engine, put them aside

27. Remove intake hoses and bleed hoses from the engine

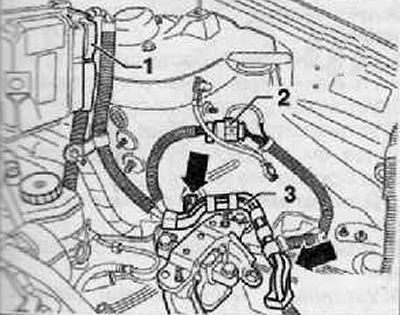

28. Disconnect the engine wiring harness connector from (1) from the engine pressure block, as shown in the figure below.

29. Disconnect the wiring harness connector (2), shown in the figure below.

30. Release the wire holder from the fixed position (3) (arrows) as shown in the picture below.

31. The engine wiring harness should be removed and secured to the engine.

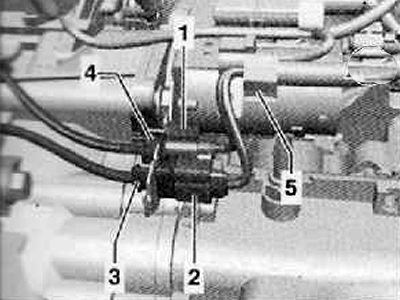

32. Disconnect wiring harness connectors (1) And (2), shown in the figure below, release the conduit clamp (5).

33. Remove the exhaust gas catalyst from the front of the exhaust pipe (for details, see the relevant section in the chapter Intake and exhaust system).

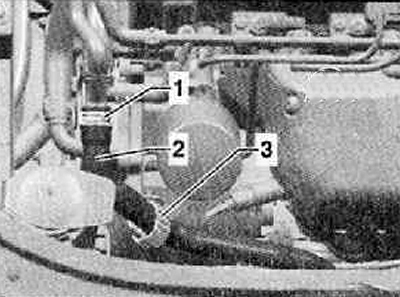

34. Unscrew the fastening screws (1) And (3), remove the bottom coolant pipe (2), as shown in the figure below.

35. Unscrew the fastening bolts (arrows) and remove the oscillating support shown in the figure below.

For vehicles with air conditioning

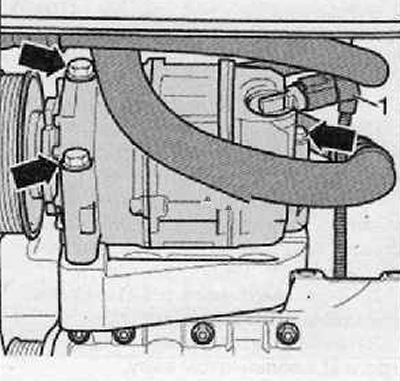

36. Remove the poly-V-belt drive attachments (for details, see the relevant section in this chapter).

37. Disconnect the wiring harness connector (1) electromagnetic clutch on the air conditioning compressor

Attention. Risk of injury from refrigerant.

Attention.

- Risk of damage to pipes and hoses for the refrigerant of the air conditioning system.

- Pipelines and hoses of the air conditioning system must not be twisted or bent at an acute angle.

38. Unscrew the fastening screws (arrows) air conditioner compressor.

39. Attach the A/C compressor to the complete body front wall module.

Continuation for all cars

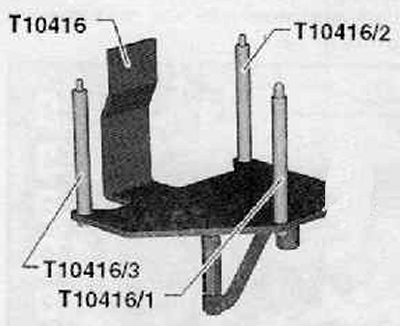

40. To be able to lower the engine with gearbox, use the special engine support bracket -T10416- with adapters -/1-, -/2- and -/3-.

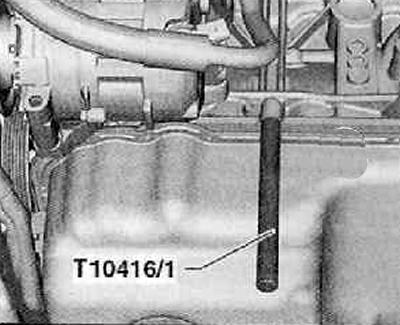

41. Screw adapter T10416/1 into the cylinder block until it stops, as shown in the figure below.

42. Fit engine support bracket -TI0416- with adapters -/2- and -/3- to cylinder block.

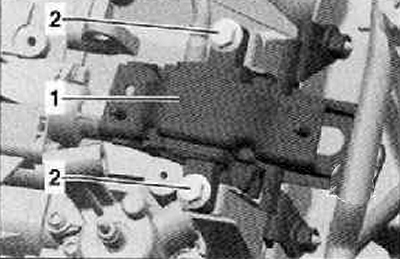

43. Attach bracket for engine support -T10416- with screw (1) to the cylinder block; screw must be tightened by hand.

44. Tighten all screws on engine support bracket -T10416- to 20 Nm.

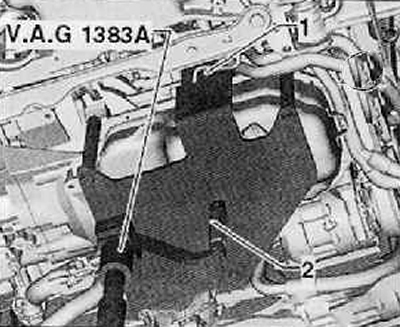

45. Position engine and gearbox remover and installer -VAG 1383 A- on engine support bracket -T10416- and raise engine with gearbox slightly.

Note.

- Check that all hose and wire connections between the engine, gearbox and body are disconnected and. if necessary, separate them.

- Use the ladder -U4S 5085- to remove the fixing bolts.

46. Unscrew the fastening nut (3) and disconnect the ground wire from the engine support (4), shown in the figure below.

47. Unscrew the fastening bolts (2) engine mounts (1), as shown in the figure below.

48. Unscrew the fastening bolts (2) gearbox mounts (1), as shown in the figure below.

Note.

- When lowering the engine with gearbox, the assistance of a second mechanic is required.

- The engine with gearbox must be lowered carefully to prevent damage.

49. Move the engine/gearbox assembly as far forward as possible, then lower it slowly down.

50. Disconnect the gearbox from the engine.

Installation

1. Installation is made in reverse order to removal.

Attention.

- For any assembly work, especially in the engine compartment due to the narrow assembly area, the following instructions must be observed:

- • Any kind of pipelines (e.g. for fuel, hydraulic system, coolant, brake fluid, vacuum lines) and electrical wires should be laid in such a way as to restore their original condition.

- • Ensure that there is sufficient space between the piping and moving or hot components to avoid damaging the piping.

Note.

- All wire connections must be fixed in the same place during assembly.

- Secure all hose connections with tube clamps.

- During assembly work, self-locking nuts and screws must be replaced.

- Replace screws that are further tightened with an angle of rotation, as well as O-rings and seals.

- Observe all safety precautions and instructions for assembly work on the power supply system, fuel injection and ignition, charge air system with turbocharger and further - also observe the principles of cleanliness.

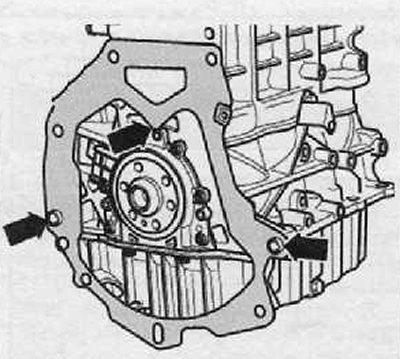

2. Check the presence of guide pins in the cylinder block for centering the engine and gearbox and, if necessary, install them.

3. Make sure that the intermediate plate is suspended from the flange seal and that it is mounted on the dowel sleeves (arrows).

For vehicles with manual transmission

4. Clean the splines of the input shaft and, on the already used clutch disc, clean the splines of the hub, remove rust and apply a very thin layer of grease -G 000 100- to the splines. Slide the disc along the drive shaft back and forth until. until the hub slides easily on the shaft. Always remove excess grease.

5. After installing the clutch, check that the clutch disc is centered correctly.

6. Check the clutch release bearing for wear. A worn clutch release bearing should be replaced.

For vehicles with automatic transmission

7. Replace needle bearing (arrow) in the crankshaft.

8. Install the selector lever cable tie to the gearbox.

Continuation for all cars

9. Connect the gearbox to the engine.

10. When installing the engine/gearbox assembly, make sure that there is sufficient space towards the axle suspension mount, A/C compressor and fan for additional cooling.

11. To attach the engine/gearbox assembly to the engine mount and gearbox bearing, hand-tighten the new mounting bolts.

12. Adjust the unit support, finally tighten the fastening bolts.

13. Install the oscillator.

14. Install drive shafts (more. see the relevant section in chapter Drive shafts).

For vehicles with air conditioning

15. Install the air conditioning compressor.

16. Install the V-ribbed implement drive belt.

Continuation for all cars

17. Install the clutch release slave cylinder (for details, see the relevant section in chapter Manual Transmission).

18. Install the gearshift drive and, if necessary, adjust it.

19. Install the engine wiring harness, connect it to the engine control unit.

20. Install the exhaust gas catalyst with the front of the exhaust pipe (for details, see the relevant section in chapter Intake and exhaust system).

21. Install the battery (for details, see the relevant section in chapter Engine electrical equipment).

22. Check oil level.

23. After filling the cooling system, remove air from it.

24. Count all fault memories and reset all faults loaded about them in connection with the removal and installation of the engine. After resetting the contents of the fault memory of the engine control unit, it is necessary to generate the readiness code again.

25. Carry out a test run.

26. Subsequently, a test of the vehicle system should be carried out and any malfunctions that may have appeared should be eliminated.