Removing

1. Turn off the ignition. Disconnect the negative terminal from the battery.

2. Remove the lower protective casing of the engine compartment.

3. Drain the coolant into a previously prepared container.

4. Remove the top timing chain cover (more, see relevant section in this chapter).

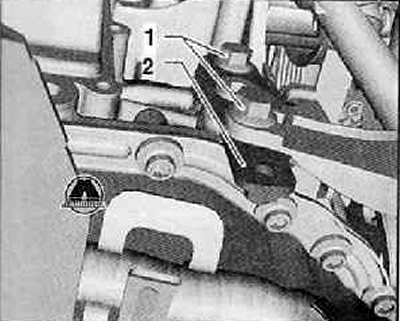

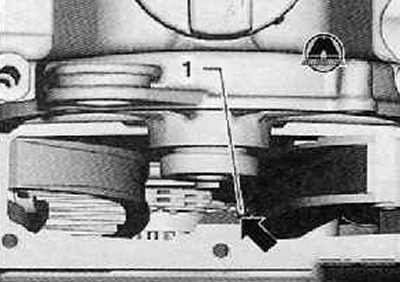

5. Remove fixing screws (1) remove the coolant pipe holder (2), as shown in the figure below.

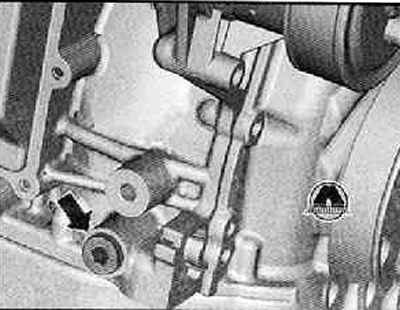

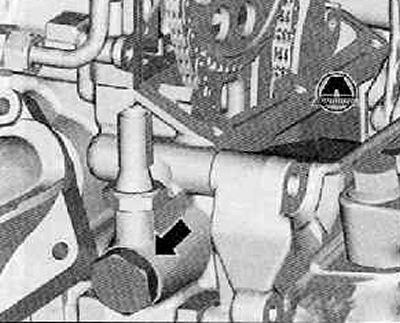

6. Unscrew the screw plug (arrow) from the cylinder block as shown in the figure below.

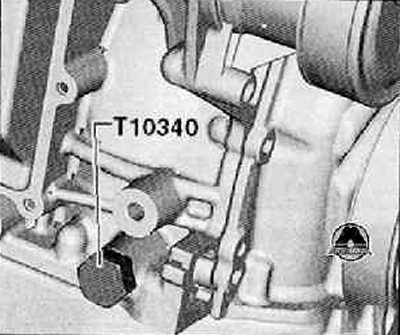

7. Screw the locking screw -T10340- into the cylinder block as far as it will go, as shown in the figure below.

Attention. If the locking screw -T10340- cannot be screwed in as far as it will go, the crankshaft is not in the correct position. In this case, you must do the following:

- Unscrew the locking screw.

- Rotate crankshaft 90° (¼ turn) in the direction of rotation of the motor shaft.

- Screw locking screw -T10340- into cylinder block as far as it will go.

- Locking screw -110340- must be tightened with a tightening torque of 30 Nm.

8. Turn the crankshaft to the stop in the direction of rotation of the engine shaft.

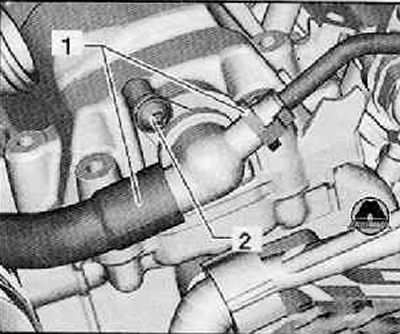

9. Disconnect both coolant hoses (1) from the check valve as shown in the figure below.

10. Unscrew the fastening screw (2), remove the check valve from the cylinder head cover.

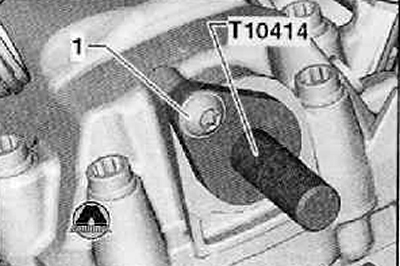

11. Install fixing bolt -T10414- as far as it will go in the cylinder head cover as shown in the figure below.

12. Tighten by hand, shown in the figure below, the fastening screw (1).

13. Remove the oil pan.

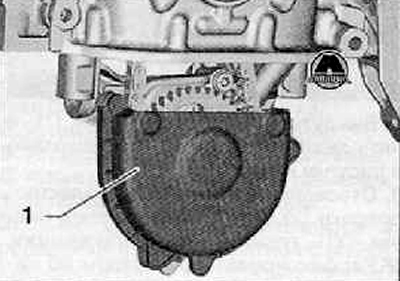

14. Remove the oil pump drive chain cover (1), as shown in the figure below.

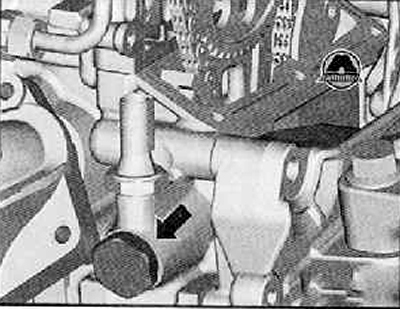

15. Unscrew the tensioner (arrow) camshaft drive chain as shown in the figure below.

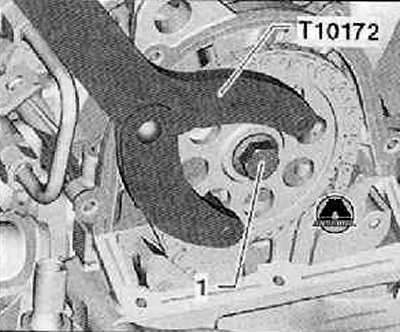

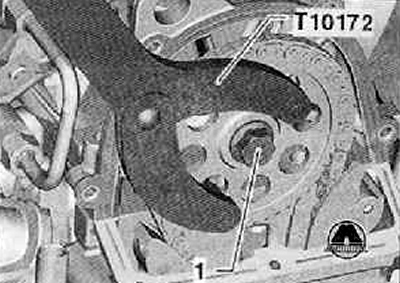

16. Hold the camshaft sprocket with counterholder -T10172- and loosen the securing bolt (1) camshaft drive gear as shown in the figure below.

17. Remove the camshaft drive gear together with the mounting bolt.

18. Put the camshaft drive chain (1) at high tide (arrow) timing chain cover as shown in the figure below.

Note. The lug on the inside of the timing chain cover prevents the camshaft timing chain from falling off.

19. Disconnect the hose leading to the air filter from the cylinder head cover.

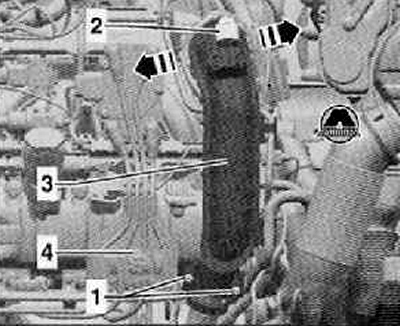

20. Unscrew the fastening screws (1), and remove the mounting clamp as shown in the figure below.

21. Disconnect the wiring harness connector (2) on the charge pressure sender -G31- shown in the figure below.

22. Release the locks in the direction of the arrow, disconnect the pressure pipe (3) first from the throttle valve module -J338- and then from the turbocharger as shown in the figure below.

23. Remove the cover, unscrew the fixing screw (4), shown in the figure below.

24. Using a special puller -T10112A-, disconnect the high-voltage wires from the spark plugs. Set high voltage wires aside.

25. Remove the high pressure pump.

26. Disconnect the wiring harness connectors from the fuel injectors.

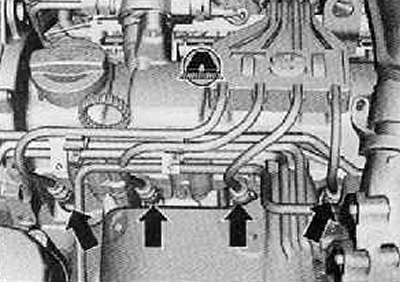

27. Unscrew the screws shown in the figure below (arrows), remove the fuel rail.

28. Remove turbocharger assembly (for details, see the relevant section in chapter Intake and exhaust system).

29. Unplug wiring harness connector at Hall sender -G40-.

30. Remove the oil level indicator.

31. Loosen the cylinder head cover bolts crosswise from the outside towards the inside and unscrew them.

32. Carefully remove the cylinder head cover.

Note. Prevent dirt and sealant residues from entering the cylinder head.

Installation

Attention.

- Before proceeding with the installation of the cylinder head, the studs (M6x70) must be screwed into the cylinder head.

- The cylinder head cover is guided by pins, thus preventing the rocker arms from slipping off the hydraulic tappets.

Note. It is impossible for any of the pistons to be at TDC.

Attention. Protective gloves and goggles should be used when working with seal remover and degreaser.

1. Eliminate residual sealant (sealant) from the sealing surfaces on the cylinder head cover and on the cylinder head with a chemical decompressor.

2. Degrease the sealing surfaces.

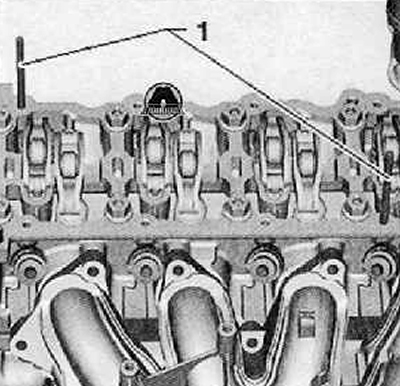

3. Before proceeding with the installation of the cylinder head cover, it is necessary to screw in two studs (M6 x 70) (1) into the cylinder head.

Attention. The cylinder head cover is sealed with 2 different sealing agents.

Note. The sealant must not be applied too thick, otherwise excess sealant may enter the lubrication holes and damage the engine.

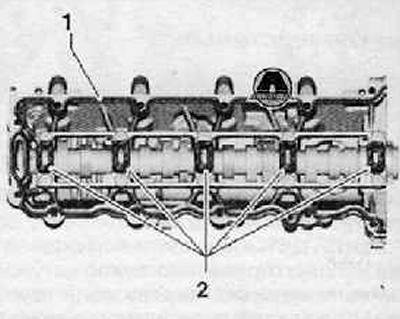

4. Apply sealant (sealant) -D 189 500 A1- on the rolled surface (1), as shown in the figure below. The diameter of the sealing agent bead should be 2...3 mm and in the places where the screw holes are located, it should be applied on the inside.

5. Apply a thin layer of sealant -D 154 103 A1- evenly on the surfaces indicated by hatching in the figure below (2).

6. Check that the rocker arms are in contact with the hydraulic compensators.

7. Push the cylinder head cover carefully through the studs and dowel pins onto the cylinder head.

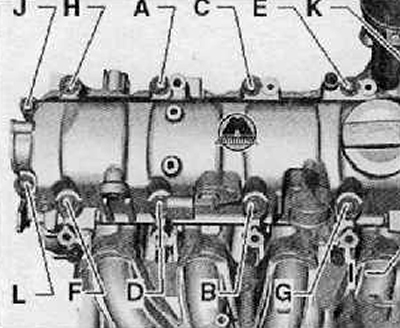

8. Tighten the new cylinder head cover fixing screws in this sequence from -A- to -J-. Tightening torque 8 Nm + turn an additional 90° (¼ turn).

Attention.

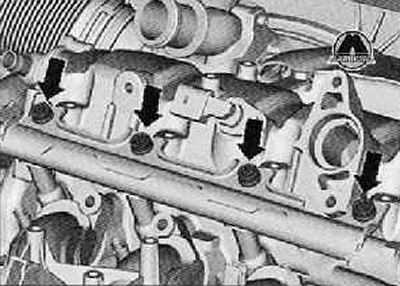

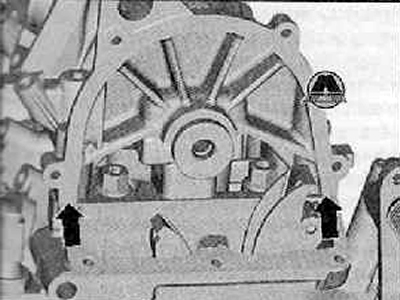

- It is imperative to remove the sealing agent for the cylinder head cover in the area shown in the figure below (arrows).

- To prevent leaks, the two sealants for the cylinder head cover and the timing chain housing must not be mixed.

9. Remove excess sealant in the area shown in the figure below (arrows).

10. Turn the crankshaft to the stop in the direction of rotation of the engine shaft.

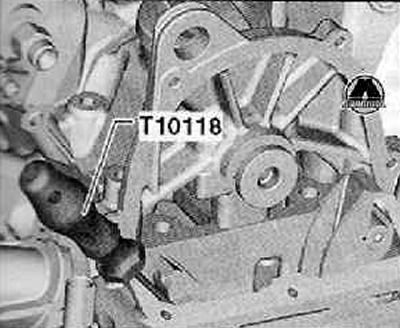

11. Lift up the camshaft timing chain using assembly tool -T10118- as shown in the figure below.

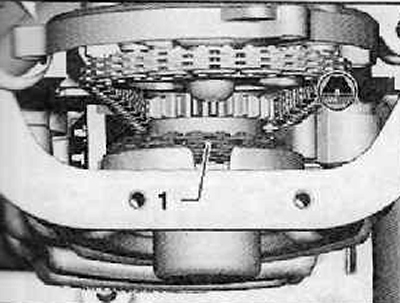

12. Check the correct position of the camshaft drive chain from below (1) on the crankshaft gear as shown in the figure below.

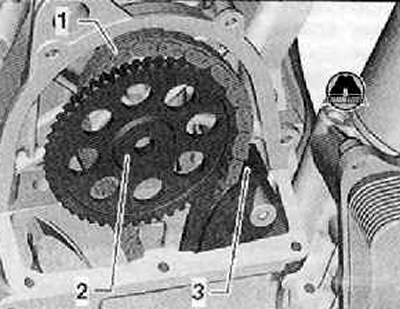

13. Put on the camshaft drive chain (1) on the chain sprocket (2), as shown in the figure below.

14. On the section of the guide rail (3) The camshaft drive chain must fit and be slightly tensioned as shown in the figure below.

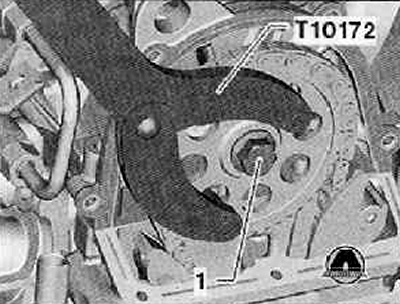

15. Hold the camshaft sprocket with counterholder -T10172- and tighten the securing bolt (1) camshaft drive gear with a tightening torque of 50 Nm as shown in the figure below. The fastening bolt must be rotated 90° (¼ turn) only after checking the distribution of the valve timing at the end of the workflow.

16. Tighten the chain tensioner with a tightening torque of 60 Nm.

17. Remove retaining bolt -T10414- from camshaft.

18. Remove locking screw -T10340- from cylinder block.

19. Turn the crankshaft two turns in the direction of rotation of the engine shaft.

20. Screw locking screw -T10340- into cylinder block as far as it will go.

21. Turn the crankshaft to the stop in the direction of rotation of the engine shaft.

22. The valve timing has been adjusted if the locking bolt -T10414- can be inserted into the camshaft.

If the distribution in time is not normal

23. Repeat valve timing (more, see relevant section in this chapter).

24. Hold the camshaft sprocket with counterholder -T10172- and turn the securing bolt (1) at 90° (¼ turn), as shown in the figure below.

25. Remove locking bolt -T10414- and locking screw -T10340-.

26. Install the upper timing chain cover (more, see relevant section in this chapter).

27. Install turbocharger assembly with exhaust manifold (for details, see the relevant section in the chapter Intake and exhaust system).

28. Install the oil pan.

29. Install the crankshaft pulley.

30. Install the high pressure pump.

31. Install fuel lines.

32. Further installation is carried out in the reverse order of removal.