Note:

- Necessary special tools, control measuring devices, and auxiliary means

- Adapter for dial indicator -T10170- or -T10170 A-.

- Camshaft position lock -T10171 A-.

- Clamping tool -T10172-.

- Locking screw -T10340-.

- Counterholder -T30004 (3415) -

- Locking pin -T40011-.

- Dial indicator, standard.

1. Remove the top decorative engine cover.

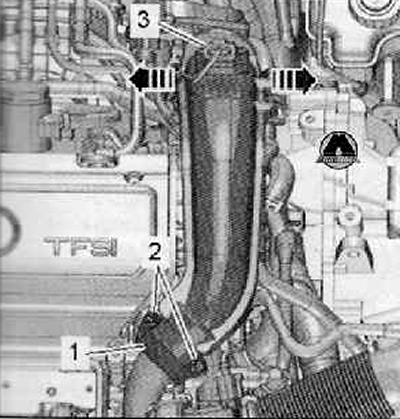

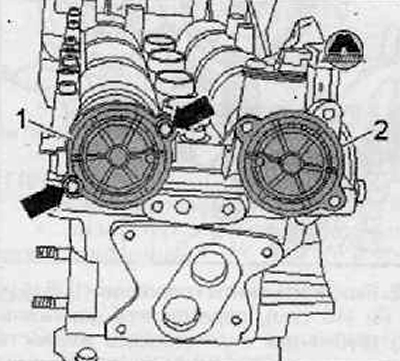

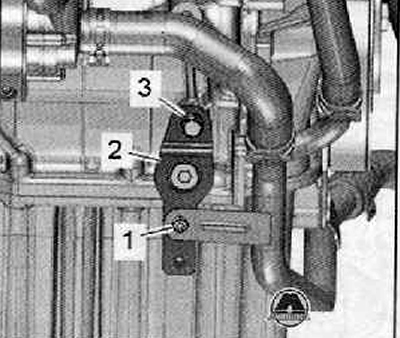

2. Unscrew the fastening screws (2), remove clamp (1), as shown in the figure below.

3. Disconnect the wiring harness connector (3) from charge pressure sender -G31- with intake air temperature sender 2 -G299- as shown in the figure below.

4. Disconnect the hoses on the pressure line and open the cable guide.

5. Move clamps outward (arrows) and pull the pressure pipe upwards as shown in the figure below.

6. Then remove the pressure pipe from the turbocharger.

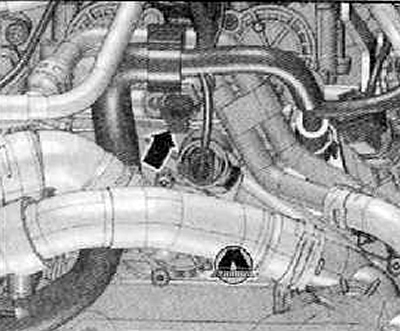

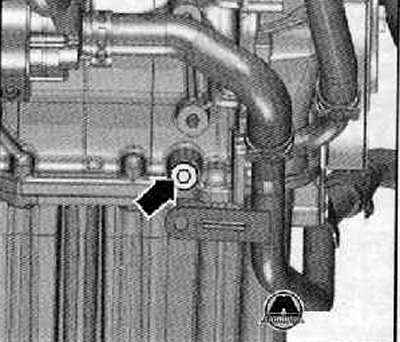

7. Disconnect the wiring harness connector (arrow) from the oil pressure drop switch -F1- as shown in the figure below.

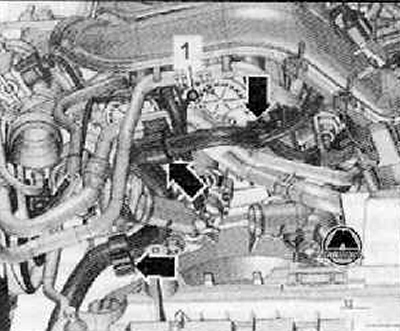

8. Unscrew the fastening screw (1) ground wires (frame), shown in the figure below.

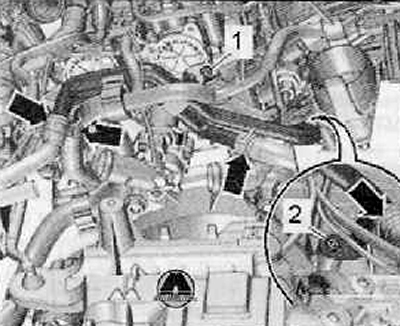

9. Unscrew the fastening screws (1) And (2), move the coolant pipes to the left to the left side of the engine compartment, as shown in the figure below.

10. Unscrew the fastening screws (arrows), remove cover (1) And (2), shown in the figure below.

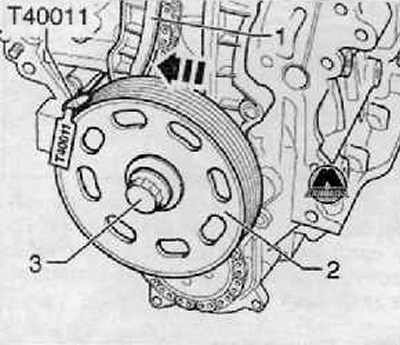

11. Remove the timing chain cover.

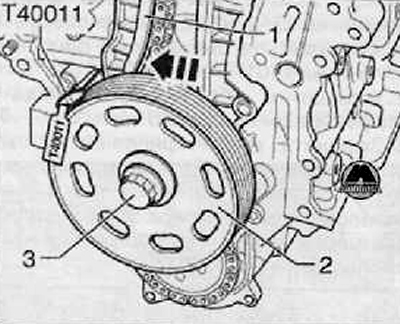

12. To be able to rotate the crankshaft, install the bearing sleeve, crankshaft pulley (2) and fixing screw (3), to be tightened to the required tightening torque (apply controller -T30004 -).

13. Remove the ignition coil of the 1st cylinder.

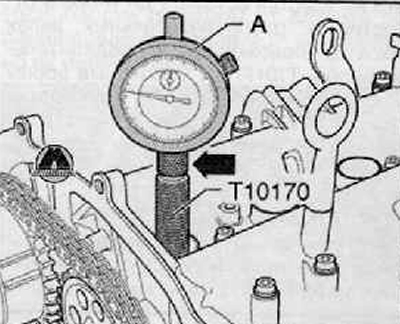

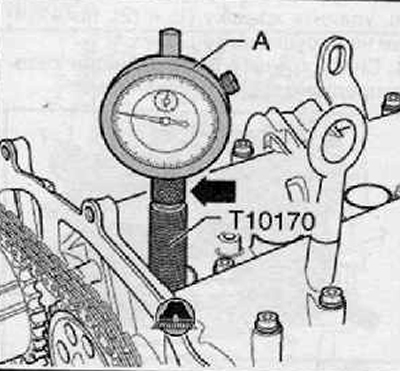

14. Screw dial indicator adapter -T10170- into the spark plug thread as far as it will go.

15. Wearing a dial indicator (A) with extension -T10170/1- up to the stop, tighten with clamping nut (arrow), as shown in the figure below.

16. Turn the crankshaft in the direction of the engine shaft until the piston of the 1st cylinder is at TDC.

17. Mark the position of the small dial indicator knob.

18. Rotate the crankshaft 45°against the direction of the engine shaft.

19. Move the tension bar (1) in the direction of the arrow as shown in the figure below, secure the piston with the locking mandrel -T40011-.

20. With a suitable felt-tip pen, the direction of movement of the camshaft drive chain should be marked (3).

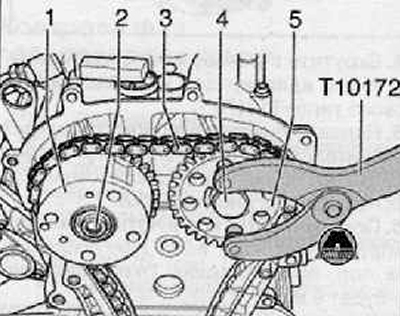

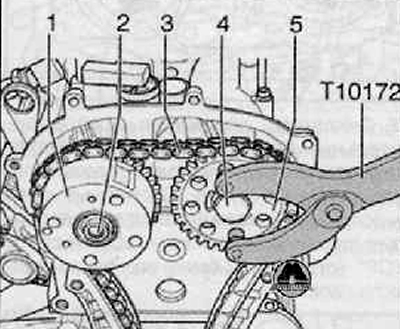

Note. The fixing screw of the mechanical camshaft adjuster -2- has a left-hand thread.

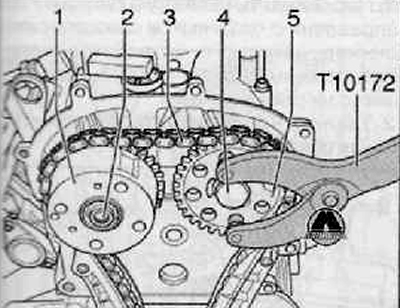

21. Remove the screws (2) And (4), remove the camshaft phase shifter (1) with camshaft drive chain (3), as shown in the figure below. Use clamping tool -T10172- for support.

22. Reinstall the camshaft phase shifter (1).

23. Replace mounting screws (2) And (4). tighten the screw (2) with tightening torque of 40 N.m and screw (4) - with the application of a moment of 50 Nm; Do not use clamping tool -T10172- for this.

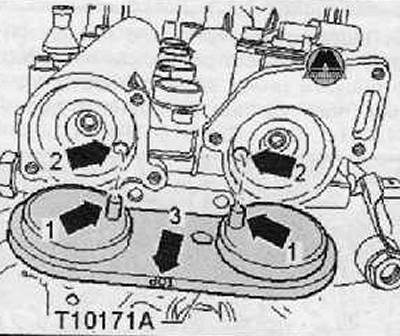

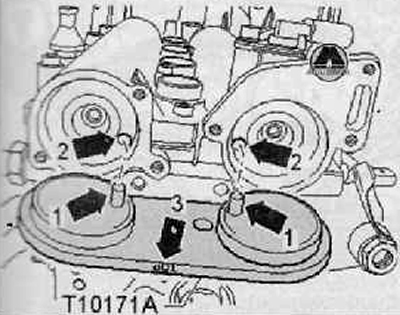

24. Turn the camshafts that actuate the intake and exhaust valves until the camshaft positioner -T10171 A- can be inserted into the holes in the camshafts as far as they will go. Stop mandrels (arrows 1) should go into the holes (arrows 2). It is necessary that the inscription "TOR" (arrow 3) could be read from above.

Note. The camshafts must not move during rotation in the axial direction.

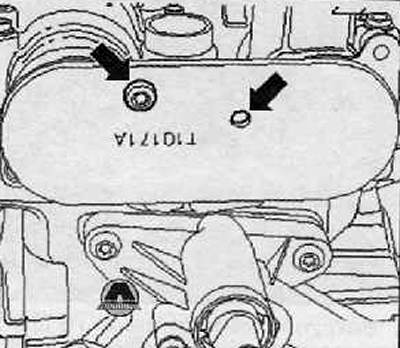

25. To lock the camshaft position lock -T10171 A-, screw the M6 screw by hand into the corresponding hole (arrows), without delay.

Note. Note that the camshaft positioner -T10171 A- has different attachment points.

26. Loosen the screws of the chain sprockets on the camshafts. To do this, use clamping tool -T10172-.

Attention. The camshaft locking tool -T10171 A- must not be used as a support tool.

27. Remove the camshaft chain sprocket.

28. Put on the camshaft chain sprockets the camshaft drive chain (respecting the direction of chain movement) and reinstall the removed chain sprocket.

29. Screw in the camshaft screws to such an extent that the chain sprockets on the camshafts can still be turned.

30. Tension camshaft timing chain by pulling out locking pin -T40011-.

31. Turn the crankshaft in the direction of the engine shaft until the piston of the 1st cylinder is at TDC. Permissible deviation from TDC of the piston of the 1st cylinder:±0.01 mm.

Note. If the crankshaft turns more than 0.01 mm past TDC, turn the crankshaft back by about 45°. Then turn it in the direction of rotation of the engine shaft to the TDC position of the 1st cylinder.

32. Unscrew the fastening screws (1) (8 Nm) And (3) (40 Nm), move holder (2) coolant pipes to the right, as shown in the figure below.

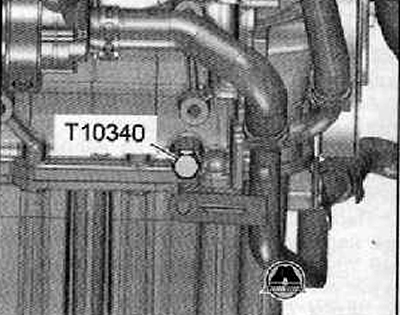

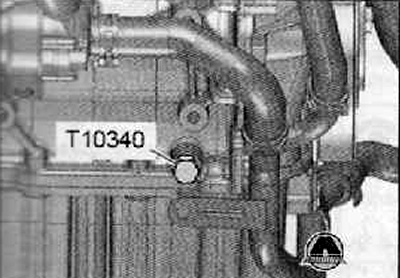

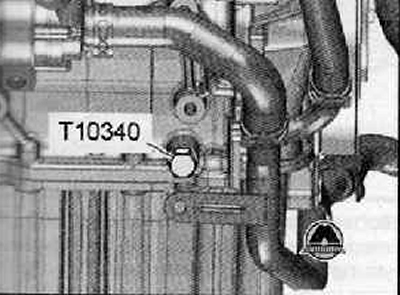

33. Remove the screw plug (arrow) TDC holes on the cylinder block.

34. Screw locking screw -T10340- into cylinder block as far as it will go, tighten to 30 Nm.

Note. The locking screw -T10340- only locks the crankshaft in the direction of rotation of the engine shaft.

35. Using the clamping device -T10172-, hold the sprockets of the chain drive of the camshafts (1) And (5) in this position and tighten the screw (2) (left hand thread) with torque application of 40 Nm and screw (4) — with the application of a torque of 50 Nm.

Note. While tightening the camshaft screws, the crankshaft must not be turned and the camshaft drive chain -3- must remain tensioned on both sides.

36. Remove the stop device -T10171 A- shown in the figure below.

37. Remove locking screw -T10340- from cylinder block.

38. Turn the crankshaft 2 turns in the direction of rotation of the engine shaft to the TDC position of the 1st cylinder. Permissible deviation from TDC of the piston of the 1st cylinder:±0.01 mm.

39. Insert the camshaft positioner -T10171 A- into the camshaft holes as far as it will go.

If the camshaft positioner -T10171 A- cannot be inserted

40. Repeat adjustment.

If the camshaft positioner -T10171 A- can be inserted

41. Screw locking screw -T10340- into cylinder block as far as it will go.

42. Tighten locking screw -T10340- to 30 Nm.

43. Remove camshaft position lock -T10171 A-, hold camshaft chain sprockets with clamping tool -T10172- and turn screws (2) (left hand thread) And (4) hard wrench additional 90' (¼ turn).

Note.

- At the fixing screw of the camshaft phase shifter (2) left thread.

- The chain sprockets on the camshafts must not be rotated on the camshaft during tightening.

44. In the future, installation is carried out in the reverse order of actions than removal. In doing so, the following instructions must be observed.

Note. The locking screw -T10340- remains in the cylinder block until the pulley is installed on the crankshaft.

45. Install the timing gear cover.

46. Install the pulley on the crankshaft.

47. Install poly V-belt.

48. Replace the sealing rings of the camshaft covers and lubricate them with oil before proceeding with installation.