Note.

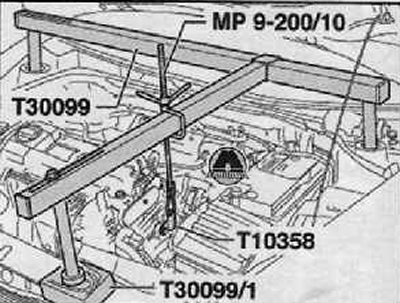

- Necessary special devices, control and measuring devices, as well as auxiliary means:

- Fixing suspension device -T30099-.

- Washer -T30099/1-.

- Holder -T10358-.

- A means to eliminate the sealing agent Gasket Stripper (storage code GST item no. R 34402), manufacturer Retech s.r.o.

Removing

Attention. Carry out pressure relief operations in the high pressure part of the supply system.

1. Drain the coolant from the engine cooling system and from the charge air cooling system.

2. Remove the following parts:

- Temperature controller housing with cylinder head.

- Inlet pipeline.

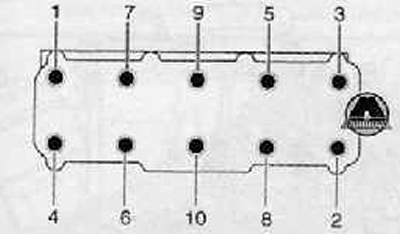

- Turbo blower.

3. Fit the suspension bracket -T30099-.

4. Remove fixing screw for gearbox, screw on retainer -T10358 - as shown.

5. After fixing the motor with the lead screws in the assembly position, prestress it slightly.

Note. Removal of the timing chain housing is carried out with the retainer -T10358- that was installed until now.

6. Remove the timing chain cover.

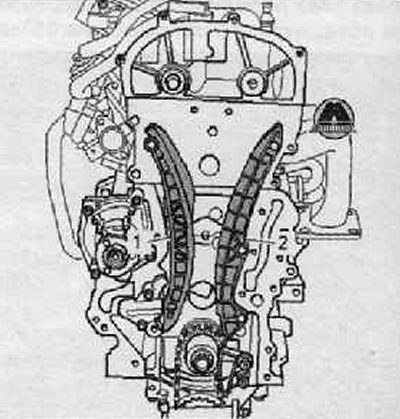

7. Remove the camshaft drive chain from the camshaft chain sprockets.

8. Remove tension rail (1) and guide rail (2) from the bearing journals. as shown in the picture below.

9. Remove the camshaft housing (for details, see the relevant section in this chapter).

10. Remove the rocker arms together with the supporting elements, put them on a clean base.

11. Do not dismantle rocker arms and hydraulic compensators.

12. Loosen the cylinder head bolts in the sequence shown in the figure below.

13. Carefully remove the cylinder head.

Installation

Note. It is impossible for any of the pistons to be at TDC.

Note.

- A new cylinder head gasket should only be removed from the packaging just before installation.

- The new gasket must be handled with great care. Damage leads to leakage.

- The cylinder head bolt holes must be free of oil and coolant.

1. Seal the cylinders with clean rags to prevent any dirt from building up in the space between the cylinder walls and the pistons.

Attention. Wear protective gloves and goggles when working with the seal remover!

2. Make sure that no foreign bodies get into the cylinders or the lubrication and coolant channels when cleaning the cylinder head and block.

3. Carefully remove the remnants of the old gasket from the cylinder head and from the cylinder block with a chemical seal remover.

4. Having adjusted the piston of the 1st cylinder to TDC, turn the crankshaft slightly back.

5. Install a new cylinder head gasket. Inscription (part number) should be visible.

6. To put on a head of the block of cylinders, at the same time it is necessary to be guided by aligning pins in the block of cylinders.

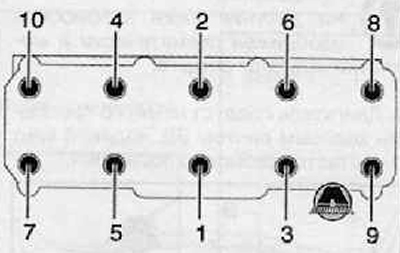

7. Having installed new bolts of fastening of a head of the block of cylinders, to tighten them by hand.

8. Bolts of fastening of a head of the block of cylinders should be tightened in the presented sequence as follows:

- All bolts must be tightened with a torque of 30 Nm.

- Then turn all the bolts additionally with a hard wrench by 90° (¼ turn).

- Then turn all screws 90°again (¼ turn).

9. Install the hydraulic tappets in the cylinder head and put the appropriate rocker arms on the ends of the valve stems and, accordingly, on the hydraulic tappets.

10. Install the camshaft housing.

11. In the future, installation is carried out in the reverse order of actions than removal.

12. After filling the cooling system, remove air from it.