Note: If components with fixed rubber bushings have been replaced, or the bolts/nuts of these components have been loosened, the suspension must be brought to an unloaded position before tightening the fasteners.

1. Rubber bushings can only be rotated a limited amount. Therefore, before tightening the fasteners, the suspension parts with rubber bushings must be brought into position corresponding to the normal position of the unloaded vehicle when driving. Otherwise, the bushings are subjected to torsion and their service life is reduced. The unloaded position with the vehicle raised is achieved by lifting the corresponding suspension with a transmission jack.

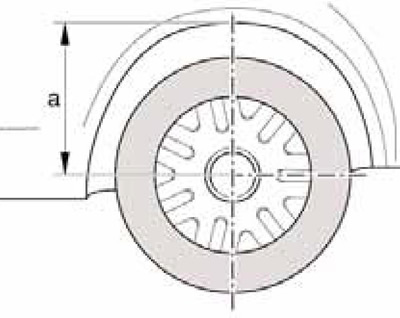

2. Before starting work with the vehicle unloaded, measure and record the distance (and on the opposite illustrations) from the center of the wheel to the top edge of the wheel arch.

2.2 Distance from the center of the wheel to the upper edge of the wheel arch

Note: An unloaded vehicle means a vehicle with full fluids and on-board tools and a spare wheel in place, without a driver, passengers or cargo.

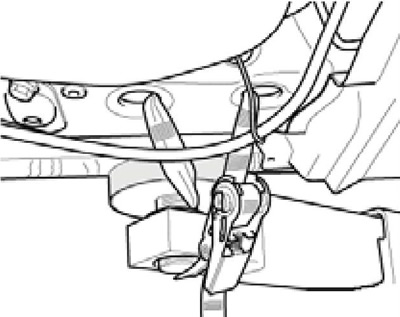

3. Before lifting the suspension parts, secure the car on the legs of the lift with straps so that the car does not slip (see resist. illustration).

2.3 Mounting the rear suspension on the lift arm

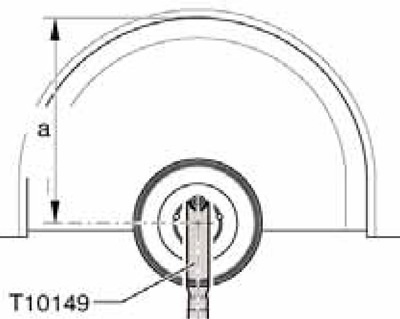

4. Remove the wheel, rotate the wheel hub so that one of the wheel bolt holes is up, and use the wheel bolt to connect the transmission jack support T10149 to the hub (see resist. illustration).

2.4 Unloaded position with raised vehicle

5. Raise the hub holder (front suspension knuckle or rear suspension arm) on the transmission jack so that the distance (and in illustration 2.4) corresponded to the distance (and in illustration 2.2).

Remark: Distance (A), corresponding to different suspension options, is also indicated in the Specifications.

In this way, the unloaded position of the suspension is achieved. Tighten the necessary fasteners, lower the hub holder, remove the T10149 support and remove the jack.