Attention: The jack is intended only for short-term lifting of the car when changing a wheel; before performing any work under the car, it is necessary to install it on special reliable props. Do not use the jack to lift heavier vehicles or other loads. When changing a wheel, people must not be in the car, and the engine must be turned off. Before using the jack, make sure that it is not damaged or deformed, and that its threaded parts are lubricated and free of foreign matter.

Stop the vehicle in a safe place on a flat, level surface, if possible with a hard surface. If necessary, turn on the hazard warning lights and set the warning triangle. Set the front wheels to straight ahead and apply the parking brake. On models with DSG, set the selector lever to position "R", and on models with manual transmission, place the shift lever in 1st gear or reverse gear. Switch off the ignition and ask the passengers to get out of the vehicle. If the luggage compartment is loaded, remove the load. If you have a trailer, uncouple it and make sure it does not pose a threat or obstruction.

Remove the spare wheel, jack, wheel wrench, appropriate hub cap remover and wheel bolt adapter (in the presence of), as described in the subsection above.

Note: The end of the adapter for security bolts, as well as the end of the threaded part of each corresponding bolt, is stamped with a code number by which you can buy a new adapter or bolt. The code should be transcribed and stored in a safe place outside the vehicle.

On both sides, support the wheel diagonally from the wheel to be replaced with wheel chocks or other suitable objects. Note: When performing the procedure on a slope, chocks should be placed on the downhill side under both wheels of a good axle. Make sure the wheel chocks will not slide on the ground. Depending on the type of rims / hubcaps installed and their mounting options, use the wire puller included in the on-board tool kit to perform the following steps.

a) Remove the steel wheel cap. To do this, hook the wire puller on the reinforced edge of the cap, insert the wheel wrench into the eye of the puller, rest it against the sidewall of the tire and separate the cap from the rim. Before installing a cap on a wheel with a security bolt, make sure that it is screwed into the hole near the tire inflation valve. When installing the hood, first fix it in the area of the valve (make sure that the slot in the cap coincides with the valve), and then push the cap away from the valve on both sides until the cap is securely locked into the disc. Do not strike the cap, so as not to damage its fixing and centering elements.

b) Remove the wheel bolt caps. To do this, slide the plastic puller onto the wheel bolt cap until it locks into place, and then pull the puller together with the cap in the direction of the arrow (see illustration 5a).

5a Removing the wheel bolt cap

c) Remove the hub cap. To do this, hook on its edge (see illustration 5b) wire puller and pull out the cap. To install the cap, press it into the disk until it locks into place.

5b Removing the wheel hub cap

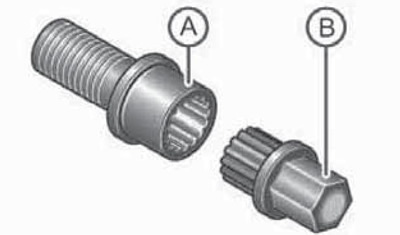

Loosen the wheel bolts on the failed wheel with a wheel wrench. If a security bolt is used, it should be removed first. To unscrew the bolt (And in illustration 6) pre-install an adapter between it and the balloon wrench (IN).

6 Security bolt and its adapter

Comment. Wheel rims and wheel bolts are structurally matched, so when installing other rims, use the appropriate wheel bolts: the correct length and the correct thrust surface shape. Reliability of fastening of wheels and work of brake system depends on it.

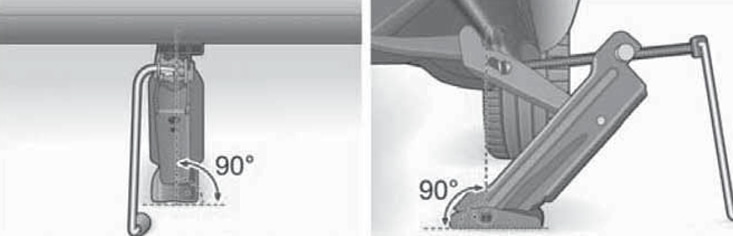

Place the head of the jack under the jacking point closest to the damaged wheel (see illustration 7a) - jacking points are indicated by triangular marks on the plastic sill plates. The jacking points are located directly below the recess in the threshold. When using a standard jack, make sure that the grip of the jack covers the vertical edge of the threshold at the level of the mark, and also make sure that the jack is located strictly vertically, and its heel rests on the ground with its entire surface (see illustration 7b). For loose ground, place a suitable pad under the heel of the jack (in winter it is useful to have a section of a wide board in the car). When using a rolling jack, install a special jig between its leg and the body, covering the edge of the threshold.

7a Support points for lifting the vehicle

7b Installing the jack

Attention: Regardless of the slope, the jack must always be in a strictly vertical position! Using the jack handle, raise the vehicle just enough so that the damaged wheel is off the ground.

Note: When the vehicle is jacked up too much, the stability of the vehicle is reduced and the vehicle can easily slide off the jack.

Completely unscrew the wheel bolts and lay them on a clean surface to prevent contamination of their threads. Remove the topmost bolt last so the wheel doesn't fall off. Remove the damaged wheel.

Note: Do not lay the removed wheel with an alloy wheel on asphalt with the outer side down, so as not to damage the paintwork of the wheel.

Remove dirt and grease from the mating surfaces of the hub and wheel, and (if necessary) wheel bolts and holes in the wheel hubs. Install a working wheel and screw its upper bolt by hand. Do not lubricate the bolts and threaded holes in the hubs.

When installing a wheel with a directional tire tread, make sure that the arrows on the tire point in the direction of rotation of the wheel when the vehicle is moving forward. If the arrows point in the opposite direction, move on such a wheel at low speed and for a minimum distance; the tire should be rearranged as soon as possible.

Screw on the wheel bolts and pre-tighten them in a criss-cross pattern ("star"). If a security bolt is used, tighten it last.

Note: Bolts must be clean and free of grease before tightening! Factory-fitted rims and bolts are structurally matched, so when installing new rims, the appropriate bolts must be used: the correct length and the correct thrust surface.

Lower the car to the ground. Check the inflation pressure of the installed wheel and adjust if necessary.

Finally, tighten the wheel bolts evenly, starting from the top, in several passes in a criss-cross pattern ("star") with a force of 120 Nm. The locking bolt should be tightened last. Depending on the equipment, fit the hub/wheel cap or wheel bolt caps.

Clean and stow the removed wheel in the luggage compartment, and the tool in its place; fix them securely. Before laying down the jack, it should be fully folded and the handle pressed against the jack.

Note: A regular wheel will not fit in the compact spare wheel well and must therefore be secured in the luggage compartment by suitable means.

Repair the removed wheel as soon as possible. If you have a tire pressure monitoring system, after changing a wheel, initialize the indicator (see chapter "Governing bodies and methods of operation").

After installing a compact spare tire or another wheel with a different tire than the rest of the tires on the vehicle (by size or, for example, by seasonal purpose), the following should be taken into account:

- do not exceed the speed of 80 km/h;

- spare wheel inflation pressure R18 must be 4.2 bar;

- limit yourself to trips to the minimum possible distances;

- the maximum mileage on the compact spare wheel mounted on the drive axle must not exceed 200 km;

- do not install several compact spare wheels at the same time;

- do not fit other summer or winter tires or snow chains to the compact spare wheel;

- be prepared for possible changes in vehicle performance, drive carefully, avoid sudden acceleration and braking, and fast cornering.