Attention: Dust resulting from worn brake linings and accumulating on brake components may contain asbestos which is hazardous to health. Do not blow this dust out with compressed air or inhale it! Do not use gasoline-based solvents to remove dust.

Note: In addition to checks at regular intervals, the condition of the brake mechanisms should be checked each time the wheels are removed or if signs of a malfunction appear in the brake system. Checking the brake fluid level is described in Section 4.

Signs of problems in the brake system

1. Any of the following symptoms may indicate a potential defect in the brake system:

- when depressing the brake pedal while the car is moving "leads away" to the side.

- The brakes make a screeching or screeching noise when braking.

- brake pedal has excessive travel.

- brake pedal pulsing (this is normal only when the ABS system is working).

- brake fluid leaks (usually visible on the inside of a tire or wheel).

2. If at least one of these signs is found, inspect the brake system immediately.

Brake lines and hoses

Note: The brake system mainly uses metal brake pipes, with the exception of flexible reinforced hoses near the wheels. Regular inspection of all these lines is very important.

3. Park your vehicle on level ground.

4. Jack up the car and place it on jack stands, then remove the wheels. Checking the vacuum hoses is described in Section 5.

5. Check all brake lines and hoses for cracks and chafing in their outer coating, as well as leaks, swelling and deformation. Check the brake hoses at the front and rear of the vehicle for signs of softening, cracking, deformation, or wear due to rubbing against other parts. Check all fittings for signs of leaks and make sure all brake line fasteners are secure.

6. Bend the brake hose back and forth with your hands to check for damage. Hoses should not be twisted.

7. Turn a steering wheel to the right and to the left against the stop. Make sure that the front brake hoses do not touch the vehicle's structural elements.

8. If brake lines are damaged or fluid leaks from them, these faults should be repaired immediately. For a more detailed description of the brake system repair procedure, refer to Chapter 9.

Checking brake pad and disc wear

9. Experience shows that due to the presence of dirt on the edge of the road, the wear of the brake pads of the right wheel is greater than that of the left. Therefore, it makes sense to check the right wheels.

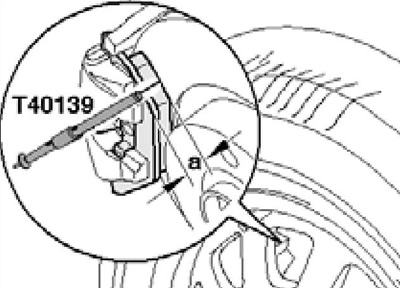

10. To measure the thickness of disc brake pads without removing the wheel, turn the wheel so that the brake mechanism is visible through the gap between the spokes of the disc (see resist. illustration), while using a mirror to measure the thickness of the inner pad. If the design of the rim does not allow you to measure the thickness of the pad without removing the wheel, remove the wheel.

8.10 Disc brake pad thickness with backing

11. Compare the measurement result with the requirements Specifications for Chapter 9 and if necessary, replace all pads of both brake mechanisms of the wheels of this axle (see chapter 9).

12. With the wheel removed, check the brake wheel cylinders for brake fluid leaks. At detection of leaks urgently repair wheel cylinders.

13. Visually check the brake discs on the inside and outside for grooves, rust and cracks. Replace defective components.

14. Measure the thickness of the brake discs in several places using a micrometer or a special caliper. You can also measure the thickness of the brake disc with a conventional caliper by placing a pad of known size on each side of the disc (e.g. two coins), and then calculating the difference between the measured value and the thickness of the pads.

15. Compare the minimum of the obtained results with the requirements Specifications for Chapter 9. If the wear limit is reached, replace both brake discs. The brake disc should also be replaced if there are large cracks or deep grooves on the running surface.

Checking and adjusting the parking brake

16. The easiest way to check the operation of the parking brake is to park the car on a steep slope (25%) with parking brake applied and transmission in neutral (must be in the vehicle during the check).

17. Adjustment of the parking brake is required only after replacing its cable, replacing the caliper or brake disc. A description of the adjustment is given in Chapter 9.

Checking the vacuum brake booster

18. With the engine off, depress the brake pedal several times - with each press, its stroke should decrease.

19. With the brake pedal depressed, start the engine - the pedal should go down.

20. Keeping the brake pedal depressed, stop the engine. If the pedal stroke does not change when holding the pedal for 30 seconds, the vacuum booster is in order.

21. If one of the above checks is unsatisfactory, repair or replace the vacuum booster (see chapter 9).