2. Connect the diagnostic tool to the diagnostic connector (see chapter 5) and use it to make sure that the temperature of the DSG fluid is no more than 35°C. Allow liquid to cool if necessary. Paragraphs 3-8 describe filter replacement and paragraphs 9-14 describe oil change.

3. Remove the engine top cover (see chapter 2).

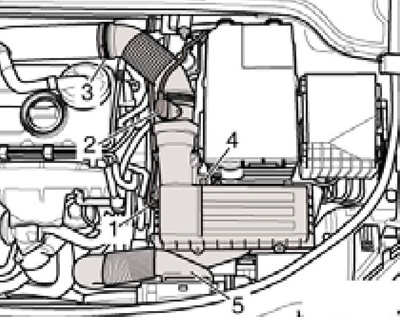

4. Disconnect the connector (2 to resist. illustrations) MAF sensor, disconnect the vent hose (1) and air duct (5). Loosen the spring clip (3) and remove the hose from the tube. Remove the screws (4) and remove the air cleaner.

21.4 Providing access to the DSG filter

5. Raise the car and remove the sound insulation panels under the engine. Place a container under the transmission to collect the DSG fluid and lower the vehicle.

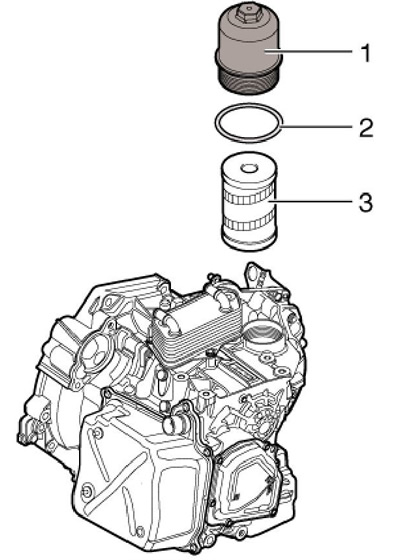

6. Unscrew the cover (1 per resist. illustrations), slightly tilt the filter (3), so that oil flows out of it, and remove it. Install a new o-ring (2), lubricated with DSG fluid.

21.6 DSG filter installation details

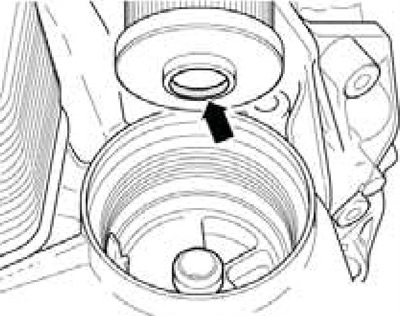

7. Moisten the O-ring in the receiving sleeve (see resist. illustration), install the filter and tighten its cover to 20 Nm.

21.7 DSG filter seal

8. Replace the removed parts.

9. Jack up the vehicle and place it on jack stands so that the vehicle is level.

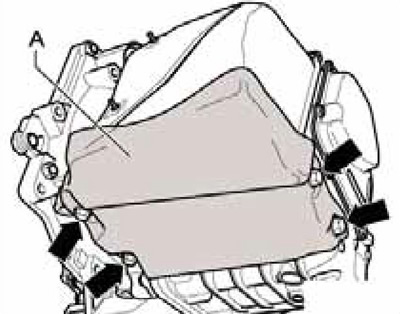

10. If present, remove the protective plate (1 per resist. illustrations) from below the DSG by unscrewing the bolts (arrows). Put on safety goggles and gloves.

21.10 DSG cover

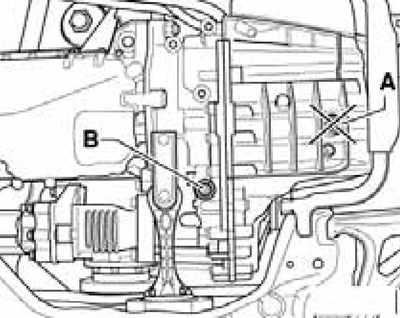

11. Turn out a stopper of a control filling opening (B on resist. illustrations) next to the rocker. Behind it is a plastic overflow tube with an 8 mm hexagon. The length of this tube determines the DSG fluid level. Unscrew the overflow tube - approximately 5 liters of DSG fluid will flow out. Screw in the overflow pipe with a force of 3 Nm.

21.11 Traffic jam (IN) control filling hole

12. Screw the adapter into the DSG control hole (And on the opposite illustrations) filling attachment VAS6262 or VAS6262A. Connect a container of DSG fluid to the filler and fill the DSG with 5.5 liters of fluid.

21.12 Adapter (A) filling device

Note: Drained fluid must not be refilled. Shake the liquid container before filling. If it is necessary to change the container, close its valve while the container is disconnected from the filling device.

13. Read the temperature using a diagnostic tool. Start the engine, depress the brake pedal and move the selector lever through all positions, waiting in each of them for about 3 seconds. Finally, return the lever to the position "R". Keep the engine running, monitor the temperature of the DSG fluid. When the temperature reaches 35 to 45°C, disconnect the adapter and allow excess liquid to drain.

14. With the correct DSG fluid level at the above temperature, a small amount of fluid flows out of the overflow tube every 30 seconds. This is due to the pulsation of the fluid level that cools the clutch. It is not necessary to compensate for the volume of dripping liquid. Tighten the control bolt with a new seal to 45 Nm and turn off the engine.