Description of the climate system

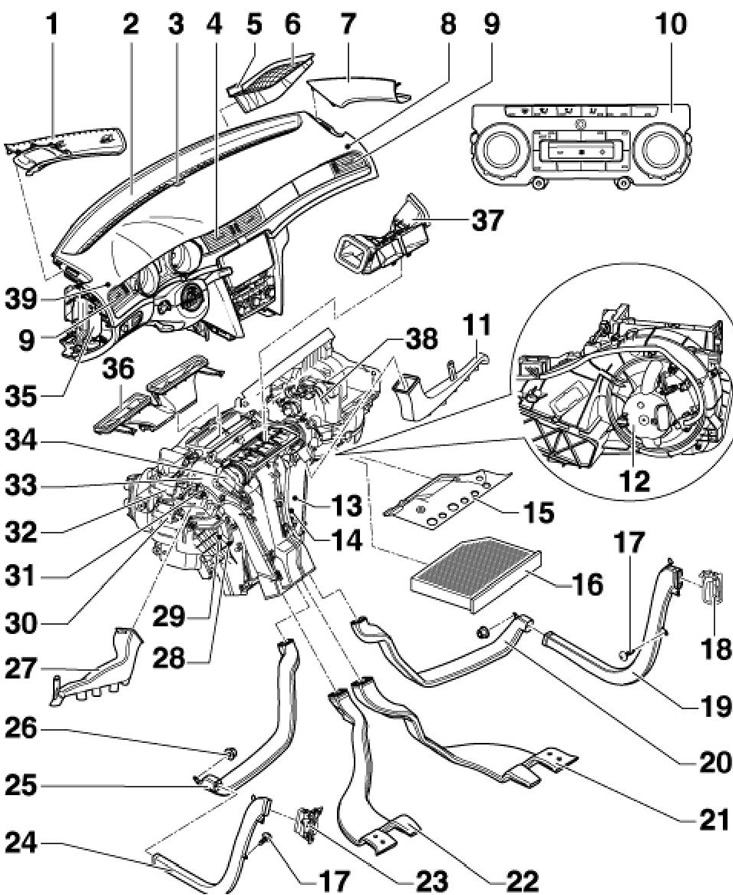

A description of the climate system control is given in Chapter "Controls and methods of operation". The main components of the climate system located in the passenger compartment are shown in illustrations 8.1a-b.

8.1a Parts of the climate system in the passenger compartment (models with refrigeration unit, manually operated)

1 Trim left pillar A, with air duct

2 Instrument panel

3 Central deflectors

4 Right-pillar trim A, with air duct

5 Side deflectors

6 Climate control panel

7, 15 Screws, 1.5 Nm

8 Actuator V113 circulation damper

9 Air duct to right footwell

10 Assembly of resistors N24 fan 11, with thermal fuse

11 Fan V2

12 Shield housing climate system

13 Evaporator outlet temperature sensor G263

14 Cabin filter

16 Rear right deflector (in B-pillar trim)

17 Air duct to deflector 16

18 Intermediate air duct to deflector 16

19 Air duct to rear right footwell

20 Air duct to rear left footwell

21 Rear left deflector (in B-pillar trim)

22 Air duct to deflector 21

23 Intermediate air duct to deflector 21

24 Nut, 1.7 Nm

25 Air duct to the left footwell

26 Auxiliary heating element Z35 (on some diesel models)

27 Heater radiator, replace coolant after replacement

28 Temperature damper actuator V68

29 Foot air temperature sensor G192 not used as of week 46, 2010

30 Actuator V145, front distribution flap, removed in the same way as actuator V426

31 Climate system housing

32 Air duct to glass deflector (at the door), is part of the cover

33 Branch pipe to the windshield vents, to remove it is necessary to remove the instrument panel

34 Sensor G191 for intake air temperature from vents 3 and 5 not used as of week 46, 2010

35 Branch pipe to deflectors 3 and 5, to remove it is necessary to remove the instrument panel

8.1b Parts of the air conditioning system in the passenger compartment (models with refrigeration unit, with automatic control)

1 Trim left pillar A, with air duct

2 Instrument panel

3 Assembling the solar radiation sensor G107 and solar radiation sensor No. 2 G134

4 Central deflectors

5 Air quality sensor G238

6 Air intake grille

7 Right-pillar trim A, with air duct

8 Sensor G151 for the temperature of the air supplied through the right vent

9 Side deflectors

10 Climate control panel, with control unit J255

11 Air duct to right footwell

12 Fan V2 with control unit L26

13 Evaporator outlet temperature sensor G263

14 Actuator V159 right temperature flap

15 Shield housing climate system

16 Cabin filter

17 Screws, 1.5 Nm

18 Rear right deflector (in B-pillar trim)

19 Air duct to deflector 18

20 Intermediate air duct to deflector 18

21 Air duct to rear right footwell

22 Air duct to rear left footwell

23 Rear left deflector (in B-pillar trim)

24 Air duct to deflector 23

25 Intermediate air duct to deflector 23

26 Nut, 1.7 Nm

27 Air duct to the left footwell

28 Auxiliary heating element Z35 (on some diesel models)

29 Heater radiator, replace coolant after replacement

30 Actuator V158 left temperature flap

31 Sensor G261 for the temperature of the air supplied to the left footwell

32 Actuator V107 defroster damper

33 Climate system housing

34 Actuator V426 front temperature flap

35 Air duct to glass deflector (at the door), is part of the cover

36 Branch pipe to the windshield vents, to remove it is necessary to remove the instrument panel

37 Branch pipe to deflectors 4 and 9, to remove it is necessary to remove the instrument panel

38 Actuator V425 distribution and circulation flaps

39 Sensor G150 for the temperature of the air supplied through the left vent

One of the main elements of the climate system is its housing, in which the main components are located: cabin filter, fan, radiator, evaporator (with air cooling function) and air distribution dampers. On diesel models, an auxiliary electric heating element can also be installed in the climate system housing.

To clean the air taken from the outside of the vehicle from small particles (dust, soot, pollen, etc.) the cabin filter is intended, which should be replaced periodically (see chapter 1).

The fan is designed for interior ventilation, i.e. to increase the intensity of air supply to the car interior; The fan speed can be adjusted. On models without automatic climate control, the fan speed is changed by changing the combination of resistances in the resistor assembly, and on models with automatic speed, an electronically controlled fan is used.

To heat the interior, the coolant heated in the engine is passed through the radiator of the climate system, giving off heat to the air passing through it. The coolant flow diagram is shown in the illustrations in Section 1.

To cool the passenger compartment, a refrigeration unit is used in which R134a refrigerant circulates. The air supplied to the cabin, passing through the evaporator, is cooled and dried, so it is recommended to turn on the refrigeration unit to reduce the humidity in the cabin (e.g. to speed up the removal of condensate from windows).

The dampers are used for: switching between supply ventilation / air circulation modes, temperature control, as well as for distributing air flows in the passenger compartment (to the legs, to the level of the chest, to the glasses and to the intermediate zones). Additional adjustment of the air flow in the cabin is carried out by means of adjustable air vents on the instrument panel and at the rear of the B-pillars.

The control unit is used to control the climate system (see chapter "Controls and methods of operation"). The shutters are driven by activators.

On models with automatic control, the set temperature is maintained based on data from the interior air temperature sensor located in the center of the climate system control unit. For proper operation of the climate system, do not cover this sensor.

On some models, an additional heater is installed that heats up the coolant regardless of the engine by burning fuel.

Description of the refrigeration unit

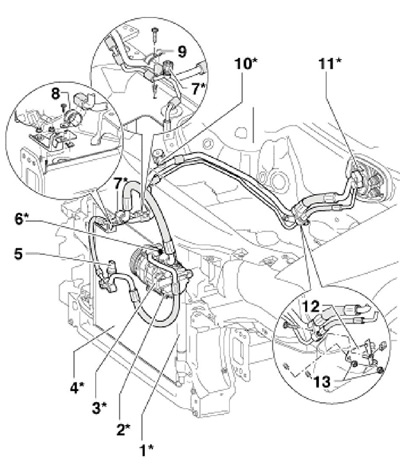

The location of the components of the refrigeration unit located in the engine compartment is shown in illustration 8.2. The operation diagram of the refrigeration unit is shown in illustration 8.3. The asterisks in these illustrations indicate parts that, along with the refrigerant lines, must be serviced by a specialist workshop.

8.2 Location of parts of the refrigeration unit in the engine compartment

1* Receiver dryer

2* Valve "N280" compressor flow control

3* Compressor

4* Capacitor

5 Sensor "G65" high pressure refrigerant

6* Refrigerant high pressure relief valve, 10 Nm, O-ring to be replaced

7* Service valve (unloading, filling and measuring) in the high pressure circuit

8 Clamp

9 holder

10* Service valve (unloading and measuring) in the low pressure circuit

11* Expansion valve

12 Refrigerant line holder

13 Nuts, 20 Nm

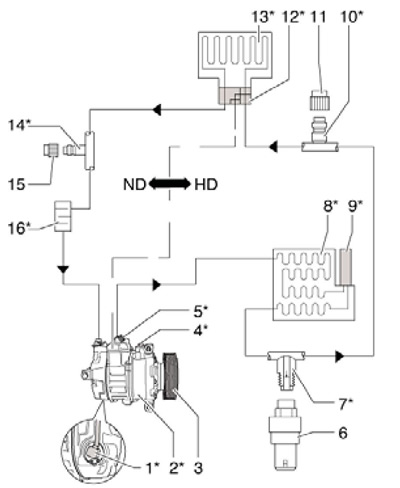

8.3 Diagram of operation of the refrigeration plant

HD High pressure circuit

ND Low pressure circuit

1* Valve "N280" compressor flow control

2* Compressor

3 Compressor pulley, with lock protection

4* Oil drain plug

5* Pressure relief valve

6 Sensor G65 high refrigerant pressure

7* Valve connection

8* Capacitor

9* Receiver dryer

10* Service valve (unloading, filling and measuring) in the high pressure circuit

11, 15 Lid

12* Expansion valve

13* Evaporator

14* Service valve (unloading and measuring) in the low pressure circuit

16* Refrigerant surge damper

Compressor (with variable flow), continuously driven by the accessory drive belt from the engine crankshaft, draws the refrigerant gas from the evaporator and compresses it. In this case, the temperature of the refrigerant rises to a value from 70 to 110°C. Under high pressure, the refrigerant is sent to the condenser, where the heat from the refrigerant is taken in by air forced through the fins of the condenser. Due to this loss of heat, the refrigerant becomes liquid and flows from the condenser to a dryer receiver located on it, which serves as a storage medium and filters out the moisture contained in the refrigerant. The thermostatic expansion valve regulates the amount of refrigerant supplied to the evaporator depending on the pressure and temperature in the evaporator. The expansion valve regulates the flow depending on the heat output so that the refrigerant does not completely change into a gaseous state before it reaches the evaporator outlet. Passing through the evaporator, the air supplied to the passenger compartment gives off heat to the cold refrigerant, and is also dried. Moisture from the air is removed under the car. The refrigerant after passing through the evaporator passes into a gaseous state. After the evaporator, the low pressure refrigerant is sucked back into the compressor.

To lubricate the components of the refrigeration unit, compressor oil is used, which circulates in the system along with the refrigerant. Black and colored O-rings are used for sealing.

A compressor without a magnetic clutch is used, i.e. when the engine is running, it is continuously driven by a belt from the crankshaft. Thus the compressor works even when the cooling function is switched off (with minimal power consumption).

Compressor flow rate controlled by valve "N280" by PWM signal from the climate control unit, depending on the required power of the refrigeration unit. Valve "N280" built into the compressor on the suction side and changes the position of the articulated disc.

When the pressure of the refrigerant is increased, detected by the sensor "G65" high pressure, the climate control unit increases the fan speed "V7" on the radiator and reduces the compressor flow if the (32 bar, e.g. with insufficient engine cooling) or too low (2 bar, e.g. in the event of a refrigerant leak) refrigerant pressure.

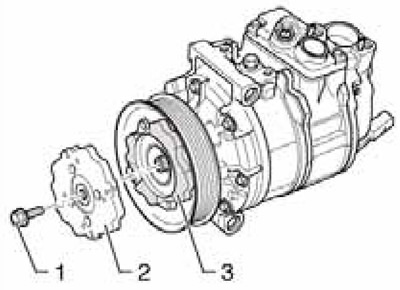

If the compressor is blocked (the shaft is jammed and stops turning), overload protection is activated. Depending on the temperature of the compressor, the clutch will either deform (2 in illustration 8.4), or wear out the rubber element (3). In any case, the pulley will be able to rotate. A stuck compressor needs to be replaced.

8.4 Compressor drive parts

To protect the refrigerant circuit from excessive pressure (e.g. due to charging excess refrigerant) a high pressure refrigerant relief valve installed on the compressor is used. The valve opens at a pressure of 40±4 bar and closes at a minimum of 31 bar. The opening of the valve to relieve pressure of the refrigerant can be determined by the extruded small plate (6 in illustration 8.2). In addition, after the valve is opened, a refrigerant oil stain forms around it.

Note: When the valve is opened, there is a risk of frostbite in the immediate vicinity of the valve.

Do not start the engine unless all refrigerant lines are connected. in this case, the compressor running without lubrication will overheat and fail. If possible, start the engine only with the refrigeration system charged. If it is necessary to start the engine with an empty refrigerant circuit, the following conditions must be met: all refrigerant lines must be connected, the compressor must be filled with at least a quarter of the total volume of refrigerant oil, the engine speed must not exceed 2000 rpm, and the operating time must be be as short as possible (no more than 10 minutes).

After installing a new compressor or after filling with refrigerant oil, before starting the engine, do the following:

- turn the compressor pulley by hand 10 turns, this will prevent damage to the compressor;

- open the vents, set the air supply to chest level, set the minimum temperature and at least the 3rd fan speed (for Climate) or maximum fan speed (for Climatronic);

- start the engine and let it idle for at least five minutes;

- turn off the engine.

Refrigeration Maintenance Safety Precautions

Do not open the refrigerant circuit, as the refrigerant may cause frostbite if it comes into contact with the skin.

Work on the refrigeration system must be carried out in a suitably equipped specialist workshop. Servicing of the system refrigeration unit should only be performed by trained service personnel who are trained in safe work practices using the proper equipment, depressurization procedures, and automotive refrigerant collection and storage techniques.

- Avoid skin contact with refrigerant.

- Wear protective goggles when working near the refrigeration unit.

- If refrigerant comes into contact with skin or eyes, do not rub the affected area. Immediately flush the affected area with running cold water for at least 15 minutes and seek qualified medical attention. Self-medication is not allowed.

- The refrigerant is stored in pressurized cylinders. Store the cylinder at a temperature not exceeding +50°C. Take care not to drop the cylinder from a height or otherwise cause damage to the cylinder.

- Work should be carried out in a well-ventilated area. The refrigerant evaporates quickly, leading to a decrease in oxygen supply and difficulty breathing.

- The gaseous refrigerant is heavier than air and collects relatively quickly at the bottom, such as under a car.

- When the refrigerant burns, poisonous gas is produced. Keep refrigerant away from open flames. Do not smoke while working on the refrigeration system.

- When welding near the refrigeration unit, do not expose it to high temperatures or open flames. Overheating can lead to an increase in pressure in the refrigerant circuit and fire.

- If the refrigerant circuit is not opened within 10 minutes after refrigerant pressure has been released, pressure may reappear due to the evaporation of the remaining refrigerant.

- Cleaning the condenser or evaporator with steam is not permitted. Use only cold water or compressed air.