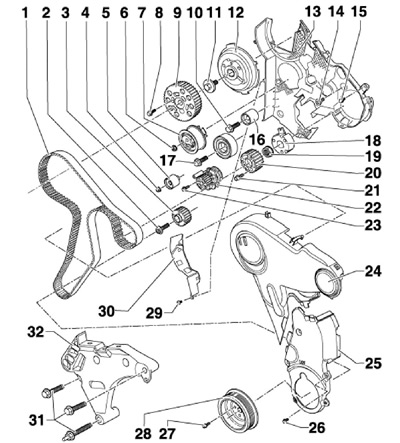

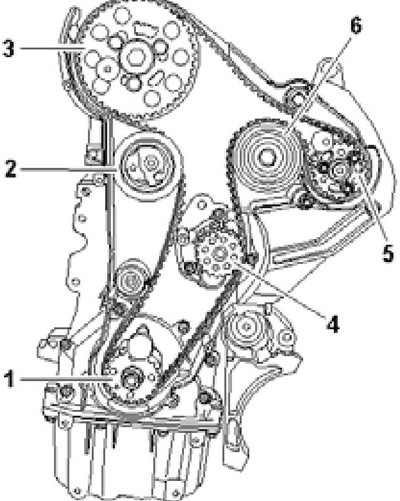

36.1 Timing belt installation details

1 timing belt

2 Gear bolt

3, to be replaced, 120 Nm, then tighten 90°

3 Crankshaft gear

4 Nut, 20 Nm

5, 16 Intermediate roller

6 Nut, 20 Nm, then retighten to 45°

7 Tension roller

8 Nut, 20 Nm, then tighten 45°

9 Camshaft gear

10 Bolt, 20 Nm

11 Bolt, 100 Nm

12 Wheel hub 9

13 Rear timing belt cover

14 Bolt, to be replaced, 20 Nm, then retighten by 45°

15 Bolt, to be replaced, 12 Nm

17 Bolt, to be replaced, 50 Nm, then retighten 90°

18 Hub TH OBD

19 Nut, 95 Nm

20 Injection pump gear

21 Bolt, to be replaced, 20 Nm, then retighten 90°

22 Water pump

23 Bolt, 15 Nm

24 Upper timing belt cover

25 Lower timing belt cover

26 Bolt, 9 Nm, installed on the fixing sealant D000 600A2

27 Bolt, to be replaced, 10 Nm, then retighten 90°

28 Crankshaft pulley

29 Bolt, 5 Nm

30 Protective plate

31 Bolt, to be replaced, 40 Nm, then retighten 180°

32 Engine bracket

Removing

2. Set the transmission to neutral to be able to rotate the crankshaft and remove the key from the ignition.

3. Remove the engine top cover (see paragraph 1 of Section 34).

4. Remove the accessory drive belt (see Section 35).

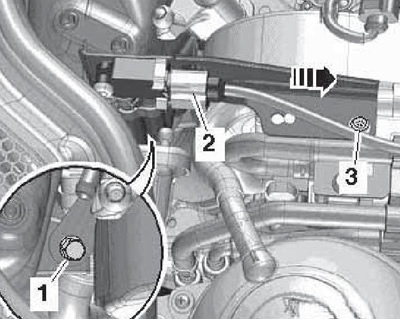

5. Disconnect the supply (2 in illustration 34.18) and return (1) fuel lines by squeezing the clamps.

6. Disconnect the connector (2 to resist. illustrations) sensor "G505" pressure difference, remove the bolt (3) and remove the bracket together with the sensor from the additional fuel pump bracket in the direction of the arrow. Set the bracket with the sensor back.

36.6 Differential pressure sensor and its bracket

Remark: Sensor "G505" very sensitive so don't let it touch other parts.

7. Remove the bolt (1 in illustration 34.20) and squeeze the neck (2) with the filling tube to the side.

Note: For clarity, the fuel filter is not shown in the illustration.

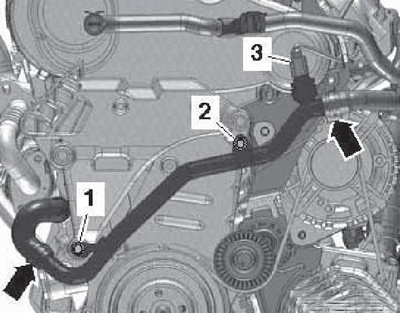

8. Release the fuel hose (2 in illustration 34.21) out of the bracket, remove the fuel line bracket upwards in the direction of the arrow and set it aside. Disconnect connector (1) additional fuel pump "V393" and remove the bolts (3). Disconnect the connector of the expansion tank and remove its bolts.

9. Loosen the bolt two turns (1 in illustration 34.22), remove the bolt (2) and give the nut (3). Separate the coolant line bracket from the fuel filter. Lay the expansion tank and fuel filter on the engine without disconnecting the hoses from them.

10. Disconnect the connector (3 on resist. illustrations) sensor "G83" coolant temperature at the radiator outlet. Give the nut (1), remove the bolt (2) and press aside the right coolant pipe with hoses connected to it.

36.10 Right coolant pipe

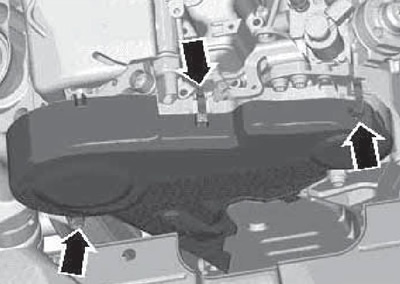

11. Press the latches (see resist. illustration) and remove the upper timing belt cover. Remove crankshaft pulley (see Section 35), without blocking the accessory drive belt tensioner.

36.11 Clips of the upper casing of the timing belt

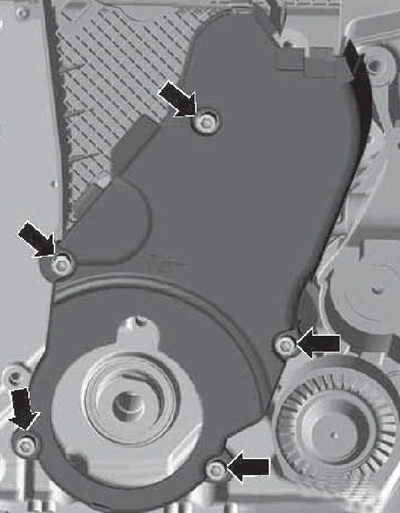

12. Remove the bolts and remove the lower timing belt cover (see resist. illustration).

36.12 Fasteners for the lower casing of the timing belt

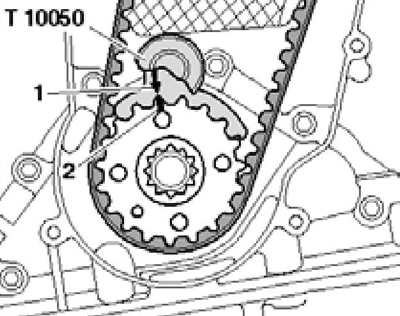

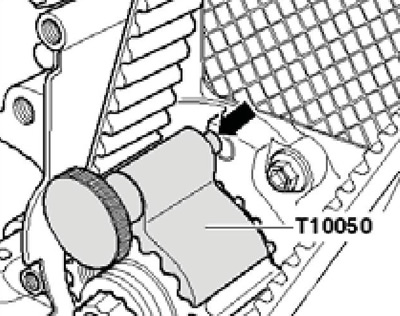

13. Turn the crankshaft clockwise to the TDC position of the piston No. 1 and fix the crankshaft gear wheel with tool T10050 (see resist. illustration). When inserting the pin of the T10050 tool into the hole in the front sealing flange, the marks on the toothed segment of the tool (1) and on the crankshaft gear (2) must match.

36.13 Fixing the crankshaft at TDC

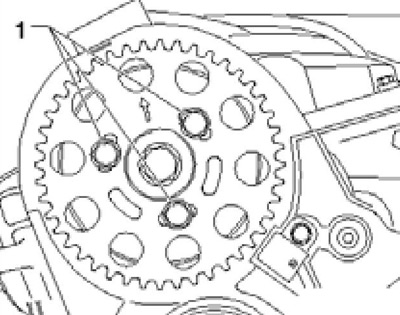

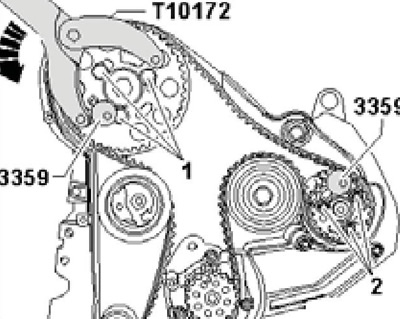

14. If the removable belt is to be reused, mark the direction of its movement on it. Lock the camshaft sprocket hub with tool N°3359 and loosen the bolts (arrows on resist. illustrations) fastening of the gear wheel by approximately 90°.

36.14 Camshaft gear bolts

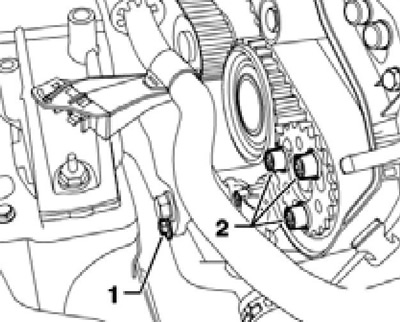

15. Remove the bolt (1 per resist. illustrations) coolant pipes and loosen the bolts (2) fixing the gear wheel of the injection pump by about 90°.

36.15 Fixing the coolant pipe (1) and gear wheel injection pump (2)

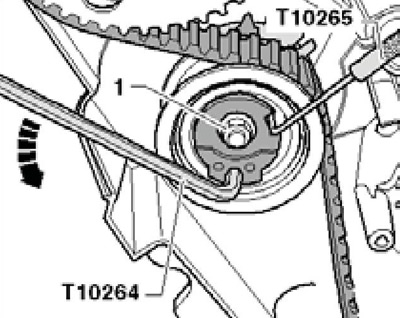

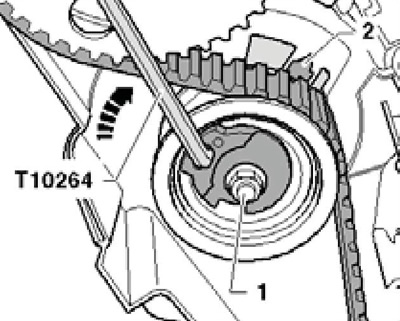

16. Loosen the nut (1 per resist. illustrations) fastening the tension roller and turn its eccentric counterclockwise (arrow) hexagon T10264 just enough to insert locking tool T10265. Block the tension roller with tool T10265.

36.16 Fixing tensioner

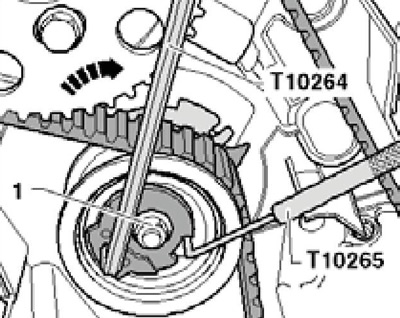

17. Turn the tension roller eccentric clockwise (arrow on resist illustrations) to the stop and tighten the nut (1) by hand. Remove the timing belt first from the large intermediate roller, and then from the remaining rollers and gears.

36.17 Removing the timing belt

Installation

Note: The timing belt tension should be adjusted on a cold engine, as The position of the tensioner indicator depends on the temperature of the engine.

Note: If the idler needs to be replaced, the motor bracket must be removed.

18. Make sure that the tension roller is locked with tool T10265 and fixed with a nut screwed all the way (see illustration 36.17).

19. Make sure the crankshaft is locked with tool T10050 (see illustration 36.13), and the camshaft hub is locked with tool No. 3359 (see illustration 36.14). Alternately replace the bolts of the gears of the camshaft and injection pump. At the same time, screw in new bolts only by hand, so that the indicated gears can be turned, but without distortion.

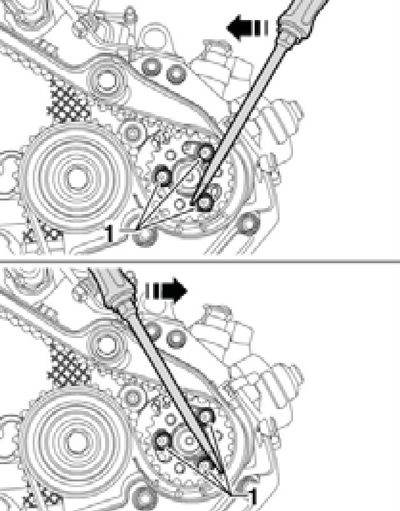

20. If necessary, turn the injection pump hub with a screwdriver behind the bolt heads (1 per resist. illustrations) enough to be fixed.

36.20 Turning the injection pump hub

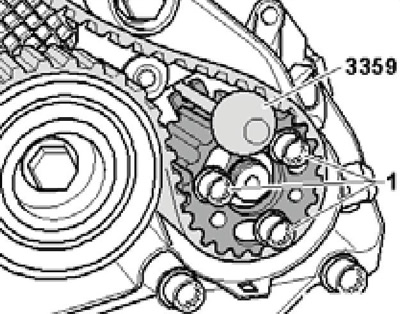

21. Lock the injection pump hub by sliding lock pin N°3359 into the adjusting hole on the outside of the injection pump gear (see resist. illustration).

36.21 Fixing the injection pump hub

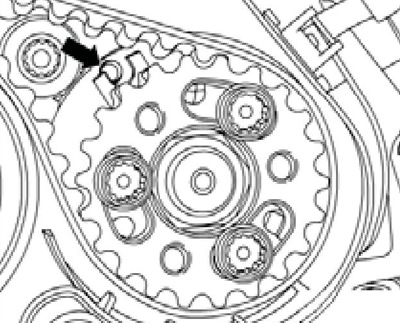

22. Turn the camshaft gears (3 on resist. illustrations) and injection pump (5) in their oblong holes clockwise until it stops. Put the timing belt on the crankshaft gear (1), pass through the tension roller (2), camshaft gears (3), water pump (4) and injection pump (5). Finally, pass the timing belt through the intermediate roller (6).

36.22 Timing belt routing diagram

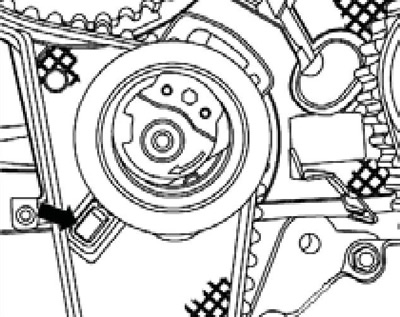

23. Loosen the idler nut and pull out tool T10265 (see illustration 36.17). Make sure the tensioner is properly seated in the rear timing belt guard (see resist. illustration).

36.23 The position of the tension roller in the rear timing belt casing

24. Install counterholder T10172 with adapters T10172 / 4 on the camshaft gear, push it in the direction of the arrow (see resist. illustration) and hold the camshaft sprocket in the preload position. In this position, tighten the bolts (1) camshaft gear, and then bolts (2) gear wheel high pressure fuel pump with a force of 20 Nm.

36.24 Tightening the camshaft gear bolts (1) and injection pump (2)

Note: The bolts should be finally tightened after checking the correct installation of the timing phases (see below).

25. Gently turn the tension roller eccentric clockwise with a T10264 hexagon so that the tension indicator (2 to resist. illustrations) located in the center of the gap in the base plate. Make sure the nut (1) does not rotate. While holding the idler pulley in this position, tighten its fixing nut to 20 Nm, and then tighten it to an angle of 45°.

36.25 Tensioning the timing belt

26. Remove the lock pins N23359 of the camshaft and injection pump, as well as the retainer T10050 of the crankshaft. Rotate the crankshaft 2 turns clockwise, set it to just before TDC, and install the crankshaft retainer T10050. Turn the crankshaft clockwise until the pin (arrow on resist illustrations) retainer T10050 entered the hole in the sealing flange.

36.26 T10050 tool pin

27. When performing the following control procedure, only the camshaft and crankshaft should be fixed. It is quite difficult to find the mounting position of the injection pump hub again, however, a slight deviation (arrow on resist illustrations) does not affect engine performance.

36.27 Injection pump adjustment deviation

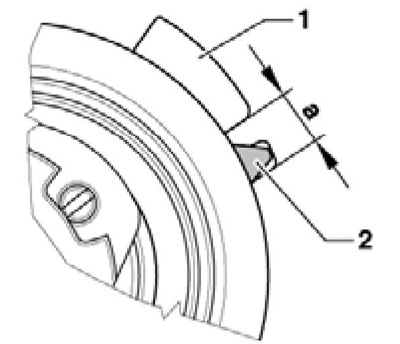

28. Check that the camshaft hub can be locked with lock pin #3359 and the indicator (2 to resist. illustrations) tension roller is located in the area (A) base plate (1).

36.28 Indicator position before timing check

29. If the camshaft hub cannot be fixed, follow the steps described in paragraphs 30-32. Otherwise, go to paragraph 33.

30. Pull out the crankshaft retainer T10050 until the pin comes out of the hole. Rotate the crankshaft counterclockwise slightly past TDC, and then slowly rotate it clockwise until the camshaft hub can be secured with lock pin #3359. Once fixed, loosen the camshaft sprocket mounting bolts on the locked hub.

31. Check the position of the T10050 retainer pin in relation to the hole in the sealing flange (see illustration 36.26). If the pin is to the left of the hole, slowly turn the crankshaft clockwise until the pin enters the hole, and tighten the camshaft sprocket mounting bolts to 20 Nm.

32. If the T10050 pin is to the right of the hole, turn the crankshaft counterclockwise slightly (so that the pin is to the left of the hole), and then clockwise until the pin enters the hole. Tighten the camshaft sprocket bolts to 20 Nm.

33. Remove the lock pin No. 3359 and the crankshaft retainer T10050 and check the timing again (see paragraphs 26-29).

34. If the camshaft hub can be fixed, tighten the camshaft cogwheel bolts at an angle of 45°, holding it from turning with T10172 and T10172 / 4 adapters. Then tighten the bolts of the gear wheel of the injection pump by an angle of 90', holding it from turning with tool T10172 and adapters T10172/8.

35. Further installation is carried out in the reverse order.