Attention: The presence of metal chips or a large number of small metal particles found during engine repairs may indicate damage to the crankshaft bearings and connecting rods. To prevent further damage from developing, thoroughly clean the oil passages and replace the oil nozzles (in the presence of), oil cooler and oil filter.

Note: If the parts to be removed are to be reused, position them so that they are in the same location and orientation during installation.

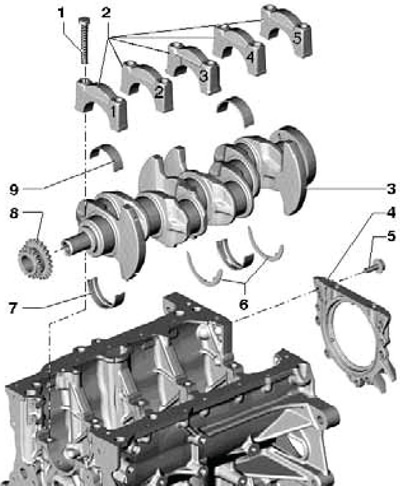

1. Details of the installation and assembly of the crankshaft and the connecting rod and piston group are indicated on the resist. illustrations.

22.1a Crankshaft installation details

1 Bolt, to be replaced, 50 Nm, then retighten 90°

2 Main bearing caps; No. 3 - with selections for washers 6

3 crankshaft

4 Sealing flange, with CKP sensor rotor and crankshaft rear oil seal, to be replaced

5 Bolt, replaceable, 10 Nm

6 Support washers for #3 main bearing cap

7 Main bearing shell, in cylinder block

8 Crankshaft sprocket

9 Main bearing shell, in its cover

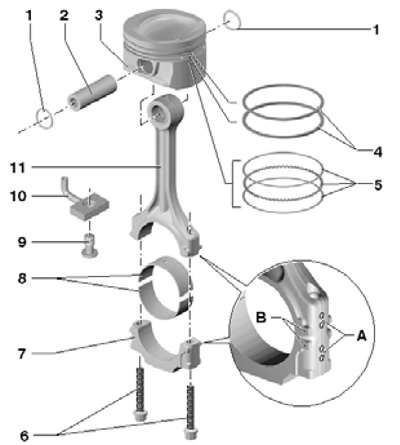

22.1b Installation details of the connecting rod and piston group

1 Retaining ring

2 Piston pin, for easier removal, heat the piston to 60°C

3 Piston with combustion chamber, the arrow on the bottom must face the timing drive

4 Compression rings, installed at intervals of 120°between locks, mark "TOR" must face the piston crown

5 Parts of the oil scraper ring

6 Cover bolts 7, to be replaced, tighten with lubricated threads and bearing surface, 30 Nm, then tighten by 90°

7 Connecting rod bearing cap, mounts only in one position and only on the paired connecting rod (see point 11)

8 Connecting rod bearing shells

9 Pressure relief valve, 2 bar, 27 Nm

10 Oil nozzle for piston cooling

11 Connecting rod, replace only complete with cap 7, marked "A " accessories for cylinder and label "IN " timing side

2. Breaking off the cover from the new connecting rod is done in the same way as on the 3.6 liter engine (see Section 14).

3. Connecting rods and connecting rod bearing caps are chipped, so they should only be replaced together. The marks on the connecting rods and connecting rod bearing caps must be on the same side.

4. The numbering of the crankshaft main bearing caps starts from the timing side. Cover #3 has slots for support washers.