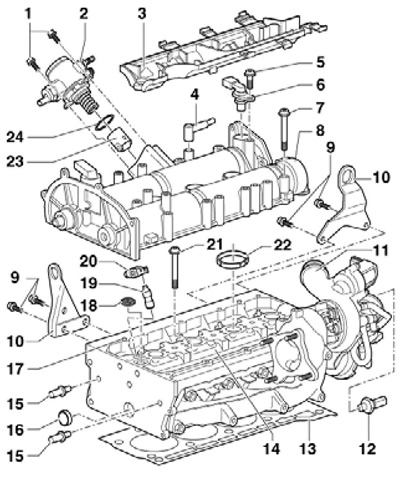

20.1a Details of installation and assembly of the cylinder head

1 Bolt, 8 Nm

2 injection pump, with valve "N276" fuel pressure adjustment

3 Wiring guide, fastened with a force of 8 Nm

4 To air cleaner

5 Bolt, 10 Nm

6 CMP sensor "G40" with sealing ring

7 Bolt, to be replaced, 10 Nm, then retighten 90°, tighten bolts from inside to outside

8 Camshaft housing

9 Bolt, 20 Nm

10 Lifting eye

11 Turbocharger

12 D/V "F1" low pressure engine oil, 25 Nm

13 Metal cylinder head gasket, to be replaced

14 Cylinder head

15 Stud bolt, 20 Nm

16 Screw plug, when installed on the sides, grease D154 102A1 is applied, installed to a depth of 1 mm

17 Centering sleeve

18 Oil filter, to be replaced

19 Valve clearance hydraulic compensator

20 Rocker, fixed on the compensator 19

21 Cylinder head bolt, to be replaced,

30 Nm, then tighten twice by 90°

22 4-piece seal, to be replaced, inserted into the cylinder head

23 Roller pusher of injection pump drive

24 O-ring, to be replaced, lubricate with engine oil before installation

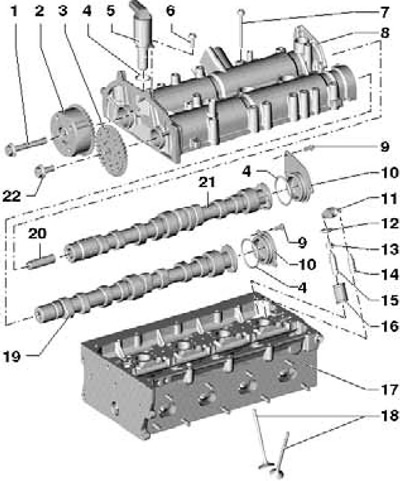

20.1b Installation details of cylinder head components

1 Bolt with left-hand thread, to be replaced, 40 Nm, then retighten by 90°

2 Shaft angle adjuster 21, not subject to disassembly

3 Camshaft sprocket

4 O-ring, lubricate with engine oil before installation

5 Solenoid valve No. 1 "N205" Timing timing adjustment

6 Bolt, 10 Nm

7 Bolt, to be replaced, 10 Nm, then retighten 90°, tighten bolts from inside to outside

8 Camshaft housing

9 Bolt, 10 Nm

10 Camshaft cover

11 Rocker, fixed on the compensator 14

12 Keys for split valve lock

13 Valve seal, to be replaced

14 Valve clearance hydraulic compensator

15 Valve guide

16 Valve spring

17 Cylinder head

18 Caps, processing is not allowed, only grinding

19 Exhaust camshaft

20 Guide sleeve

21 Intake camshaft, with cam to drive the injection pump

22 Bolt, to be replaced, 50 Nm, then retighten 90°

2. Arrange the removed parts of the valve drive in such a way that you can then install them in their original places. Lubricate all bearing surfaces with clean engine oil before installation.

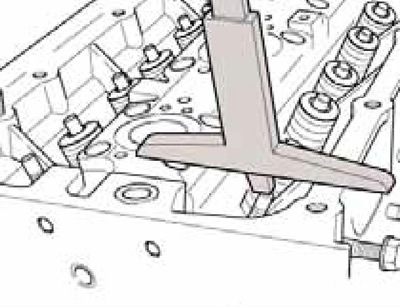

3. When machining the mating surface of the cylinder head, the valve seats should be machined so that the valves are installed deeper by the size of the cylinder head machining. At the same time, it is not allowed that the distance from the end of the valve stem to the upper mating surface of the cylinder head is less than 7.6 mm (see resist. illustration). Otherwise, the valve clearances will not be adequately compensated and the cylinder head will need to be replaced. The maximum allowable valve seat machining can be calculated as the difference between the measured value and the minimum allowable value (7.6mm).

20.3 Minimum size controlled when machining a valve seat

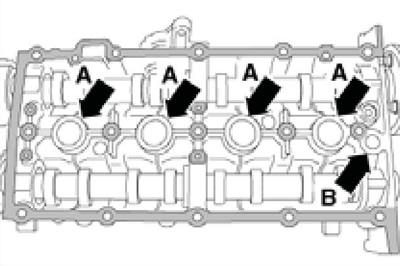

4. The camshaft housing is installed on the sealant D 188 003 A1. In this case, the sealant should only be applied to the surfaces indicated on the resist. dark illustrations. Do not apply sealant to the surfaces indicated by the arrows (A and B), because in places (A) sealing is carried out by ring gaskets, and in the area (IN) oil pickup seals are installed.

20.4 Sealing points

5. After removing the cylinder head, replace its gasket and coolant.