Note: To remove the bracket, remove the drive belt, alternator (see chapter 5), compressor (see chapter 3) and remove the bracket bolts.

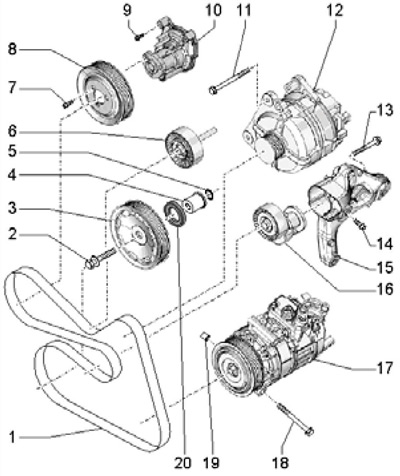

1. Details of the installation of the drive of auxiliary units are indicated on Ref. illustrations.

16.1 Accessory drive parts

1 Drive belt

2 Pulley bolt 3, to be replaced, 150 Nm, then retighten by 180°, the threads must be lubricated when tightening, but the bearing surface is not

3 Crankshaft pulley, bearing surfaces must not be lubricated

4 Bush, bearing surfaces must not be lubricated

5 O-ring, to be replaced

6 Intermediate roller, 40 Nm

7 Pulley bolt 8, 20 Nm

8 Water pump pulley

9 Bolt, 9 Nm

10 Water pump

11 Bolt, 25 Nm

12 Generator

13 Bolt, to be replaced, 40 Nm, then tighten 90'

14 Bolt, 25 Nm

15 Auxiliary bracket (tensioner and compressor)

16 Belt tensioner 1

17 Climate compressor

18 Bolt, 25 Nm

19 Centering sleeve

20 Front crankshaft oil seal

2. Remove the soundproofing under the engine compartment and the locker of the right front wheel arch (see chapter 11).

3. If the removable belt is to be reused, mark the direction of travel on the belt.

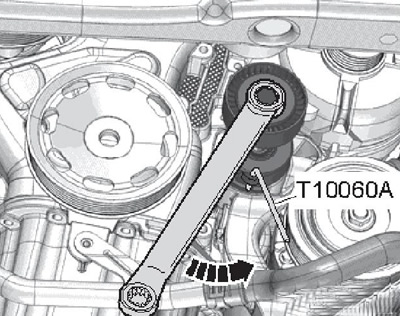

4. To loosen the belt, pull the tensioner in the direction of the arrow (see resist. illustration) with a 16 mm ring wrench, and then fix the tensioner with a 4 mm hex bar wrench or T10060A pin.

16.4 Locking the drive belt tensioner

5. Remove the accessory drive belt from the pulleys and rollers.

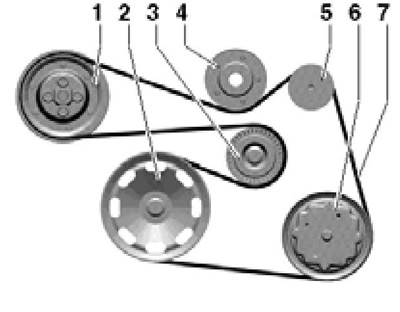

6. Installation is carried out in the reverse order. If a used belt is installed, the marks on it must face the direction of travel when the engine is running. Start laying the belt from the crankshaft pulley, and finish on the tensioner roller. Make sure the belt is properly seated on the pulleys. The belt routing diagram is indicated on the resist. illustrations.

16.6 Driving belt layout

1 Water pump pulley

2 crankshaft pulley

3 Tensioner pulley

4 Intermediate roller

5 Alternator pulley

6 Compressor pulley

7 Drive belt