Valve seat machining

Note: When machining the mating surface of the cylinder head, it is additionally required to install deeper (on the processing size of the cylinder head) valves, otherwise they could hit the pistons. At the same time, make sure that you do not go beyond the permissible minimum.

2. Processing of valves and their seats, except for lapping of valves, is not allowed.

3. When repairing an engine with leaky valves, it is not enough to just remake or replace the valve seats and valves. In particular, on engines with high mileage, it is necessary to check the valve play in the guide bushings.

4. If the play of the new intake/exhaust valve in the corresponding guide bushing exceeds 0.8 mm, the cylinder head must be replaced as guide bushings cannot be replaced individually.

5. Valve seats should only be machined to the extent necessary to obtain a proper surface finish. The maximum allowable machining dimensions must first be calculated and not exceeded, otherwise hydraulic valve clearance compensation will not be guaranteed and the cylinder head may need to be replaced.

6. To calculate the maximum allowable valve seat machining, insert the valve and press firmly against the seat.

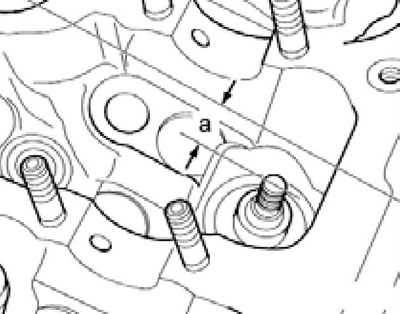

12.6 Determining the distance between the valve and the upper plane of the cylinder head

Note: If valves need to be replaced during repairs, use a new valve.

Measure the distance between the end of the valve stem and the upper plane of the cylinder head (see resist. illustration) and subtract from the result the minimum size (31.8 mm for short and 10.2 mm for long valves), - the maximum processing size for this valve will be obtained. Dimensions for processing valve seats are specified in the Specifications.

Replacing valve stem seals without removing the cylinder head

7. Remove camshafts and rocker arms with hydraulic lifters (see Section 11).

8. Remove spark plugs (see Section 14 Chapter 1) and set the piston of the corresponding cylinder to the bottom dead center position.

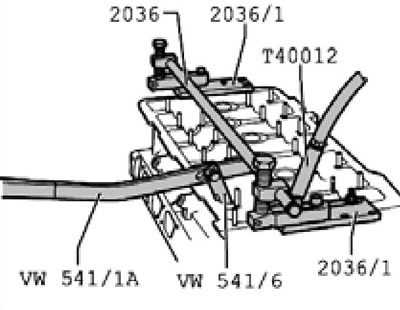

9. Install tool No. 2036 with auxiliary plates No. 2036/1 on the cylinder head (see resist. illustration), screw the T40012/1 adapter with a pressure hose into the spark plug hole and supply air through it at a pressure of at least 6 bar. Using the lever VW 541/1A and the pressure plate MP1 -211 /6, remove the valve spring, and then pull out the oil seal using the N°3364 puller.

12.9 Removing the oil seal

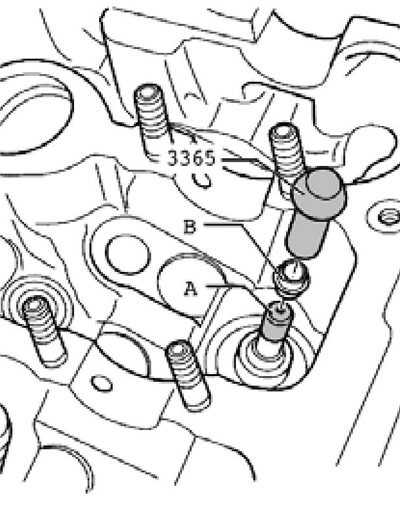

10. Put on the plastic sleeve supplied with the slinger cap (And on the opposite illustrations) on the valve stem so as not to damage the cap when installing it. Lubricate the sealing lip of the oil seal (IN), insert it into tool N23365 and carefully slide it into the guide bushing through the valve. Remove bushing (A), install the valve springs and secure them with split lock crackers.

12.10 Fitting the oil seal

11. Install rocker arms with hydraulic lifters and camshafts (see Section 9).