Removing

Note: The DSG is removed downwards, separate from the engine.

1. Set the selector lever to position "R".

2. Remove the engine top cover and air cleaner (see chapter 4).

3. Remove the battery with its holder (see chapter 5).

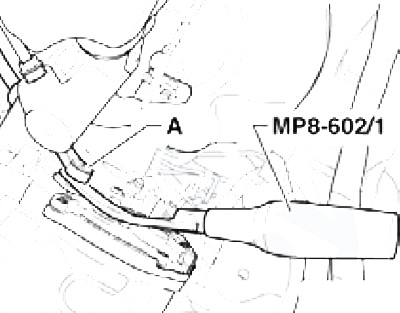

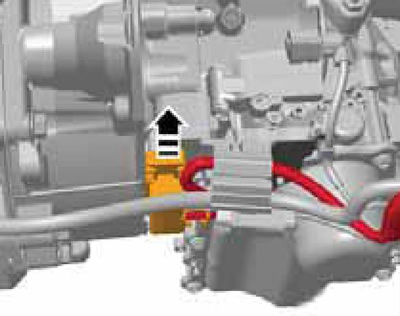

4. Using the MP8-602/1 tool, separate the selector cable from the DSG (And on the opposite illustrations).

4.4 Separating the selector cable from the selector mechanism on the DSG

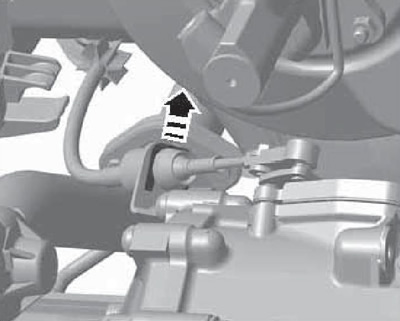

5. Remove the lock washer from the selector cable in the direction of the arrow (see resist. illustration), - the cable must remain in the installation position.

4.5 Releasing the selector cable from its holder

Note: The lock washer must not be reused. Do not bend the selector cable and do not squeeze it out of the support in the rear direction - the cable is removed from the holder when the selector mechanism is removed.

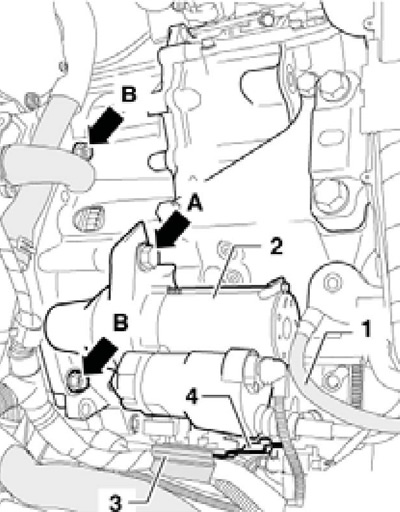

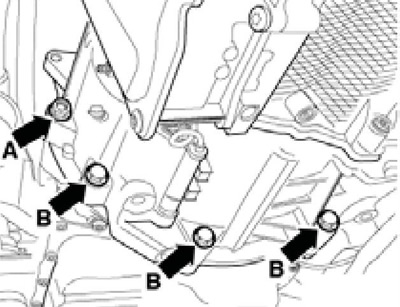

6. Remove ground wire (1 per resist. illustrations) from the DSG console bolt, disconnect from the starter (2) wiring (wire and connector, see chapter 5) and remove the bolt (A) starter. Unscrew the second starter mounting bolt, which is not visible in the illustration, and remove the starter. Remove the bolts (IN) DSG mounts. separate the wire connection from the holder (3) along with wiring (4) and put them aside. Remove holder from DSG (4).

4.6 Details on the top of the DSG

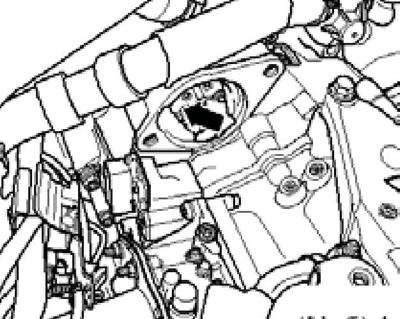

7. On some engines, one of the bolts is located in the opening for installing the starter - unscrew this bolt (see resist. illustration).

4.7 DSG mounting bolt in starter mounting hole

8. Remove the electrostatic charge from yourself, remove the cap of the block connector "Mechatronic" in the direction of the arrow (see resist. illustration) and disconnect the connector.

4.8 Block connector "Mechatronic"

9. Remove the filling pieces from the upper edges of both wings. If present, remove the connections located in the area of the engine lifting lug. Screw bracket T10346 into the rear of the three holes in the battery holder using an M6 bolt or one of the battery holder bolts (see illustration 5.11 Chapter 6). Install supports MP9-200 (№10-222A) behind the hood pillar so that their heel is positioned as illustrated (see callout): behind the bolt (1) and on the side of the bolt (2). Hook the support spindles to bracket T10346 and to the front left engine lifting eye. Slightly unload the support of the power unit. without lifting it from the supports.

10. On models with splined differential shafts (until 11.2008) have an assistant depress the brake pedal and loosen the left front wheel hub bolt and loosen the front wheel bolts. Raise the vehicle.

Caution: After removing the hub bolt, do not lower the vehicle so that it rests on the wheels.

11. Remove the front wheels, soundproofing under the engine compartment and the locker of the front left wheel arch (see chapter 11).

12. Remove charge air hose from intercooler (bottom left), as well as the charge air tube.

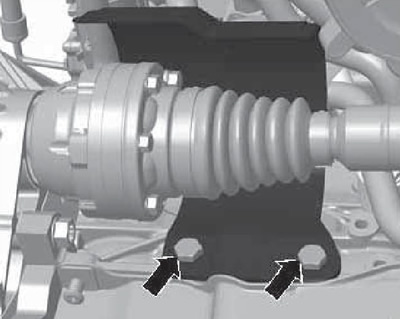

13. Turn out two bolts (see resist. illustration) and remove the protective casing of the right drive shaft from the engine.

4.13 Fastening of the casing of the right drive shaft

14. Turn out bolts (A-C in Illustration 5.20 of Chapter 6) and remove the swing arm.

15. Separate the exhaust system on a double clamp and remove its bracket from the subframe. Tie up the exhaust pipe.

16. Disconnect the engine oil temperature and level sensor connector on the underside of the engine oil pan (see chapter 2). Release the wiring of this sensor from the holder.

17. Disconnect its rack from the anti-roll bar, fix the subframe and remove it together with the console without steering gear, left arm and stabilizer bar (see chapter 10).

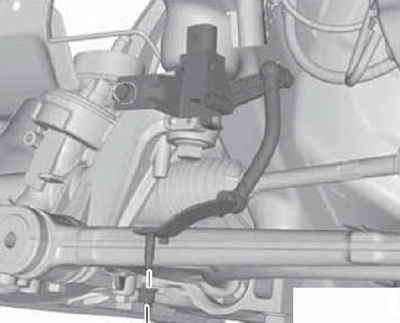

18. If available, remove the left sensor "G78" front suspension height (see resist. illustration).

4.18 Front suspension height sensor

19. On models with splined differential shafts (until 11.2008) give three nuts (see resist. illustration) and separate the ball joint from the right suspension arm (see chapter 10). Disconnect both drive shafts from the differential splined shafts and remove the left drive shaft (see chapter 8). Tie up the right drive shaft as far as possible (see illustration 4.20), without damaging its protective coating.

4.19 Ball joint nuts

20. On modules with flanged differential shafts (since 11.2008) disconnect the drive shafts from them (see chapter 8) and tie them up as far as you can (see resist. illustration), without damaging the protective coating.

4.20 Fixing the drive shaft to the suspension strut

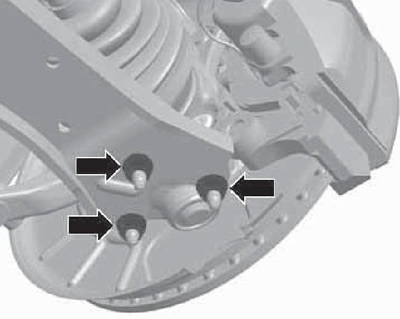

21. Turn out the bottom bolts of fastening of DSG to the engine (see resist. illustration).

4.21 DSG bottom bolts

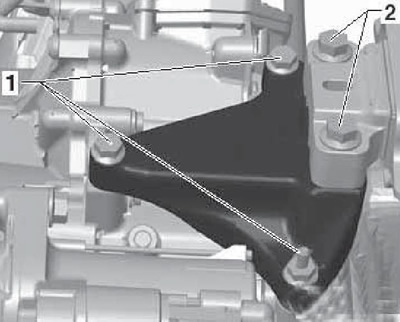

22. Loosen the bolts (1 per resist. illustrations) console DSG about one turn and remove the bolts (2).

4.22 Fixing the DSG support

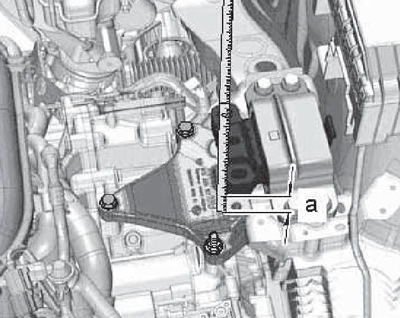

23. Lower the power unit on the MP9-200 spindles (№10-222A) so that the distance (and on the opposite illustrations) was 60-70 mm. Then unscrew the bolts (1 in illustration 4.22) console fasteners and remove it.

4.23 DSG lowering dimension

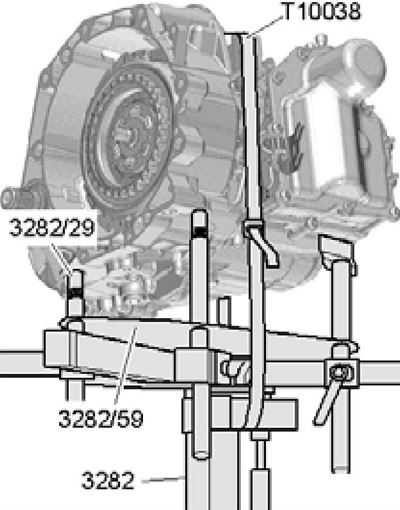

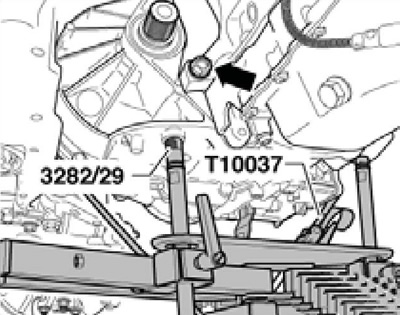

24. Install transmission support #3282 with adjustment plate #3282/59 (see resist. illustration) on the transmission jack and place it under the DSG. Align the support parallel to the DSG and screw the bolt No. 3282/29 into the DSG. Fasten the DSG to the support with T10038 strap.

4.24 DSG removal tools

25. Turn out the remained bolt of fastening DSG (arrow B on resist. illustrations), push the DSG away from the engine on the dowel sleeves and lower it slightly, disengaging the selector cable from its support on the DSG. Pull the DSG down out of the engine compartment, being careful not to damage the wiring and hoses.

4.25 Last DSG mounting bolt

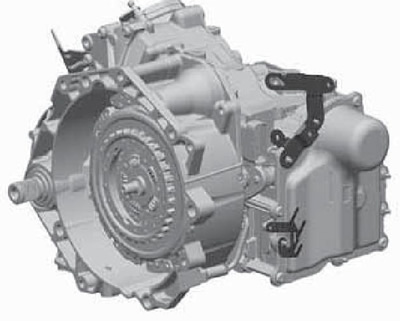

26. If you are going to install a new DSG, rearrange the brackets on it (see resist. illustration), taken from the front of the removed DSG.

4.26 DSG brackets

27. Replace the needle bearing in the crankshaft (see chapter 2).

Installation

28. Installation is carried out in the reverse order. Pay attention to the following features.

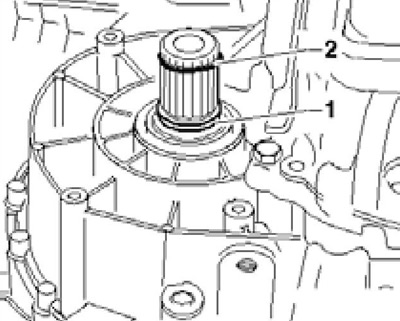

29. If an old DSG is installed, replace the o-rings (1 per resist. illustrations) and retaining rings (2) on the splined shafts of the differential.

4.29 O-ring and circlip on the splined shaft

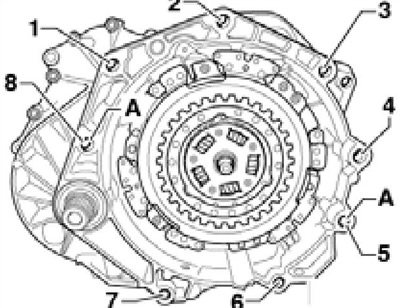

30. Check for two centering sleeves (And on the opposite illustrations) between engine and transmission. Check the correct position of the intermediate plate. The size of the bolts is also indicated on the resist. illustrations. Tighten the M12 bolts with a force of 80 Nm, and the M10 bolts with a force of 40 Nm.

4.30 Transmission to engine bolts

1, 2, 4, 5 M12x65, DSG side

3 M12x50, DSG side

6.7 M10x25, engine side

8 M12x65, engine side

A Centering sleeves

31. It should be possible to move the engine and transmission by hand to align their flanges perfectly. If the engine/transmission does not move by hand, something is wrong. Adjust the position of the transmission support so that the DSG and the engine are aligned with each other, slightly rotate the crankshaft if necessary.

32. The tightening forces of the transmission support fasteners are indicated in Section "Removal and installation of the engine" Chapters 2.

33. Use a new selector cable lock washer (see illustration 4.5). Make sure the cable is routed correctly.

34. Finally, adjust the selector cable and use the diagnostic tool to apply the basic settings for the DSG.