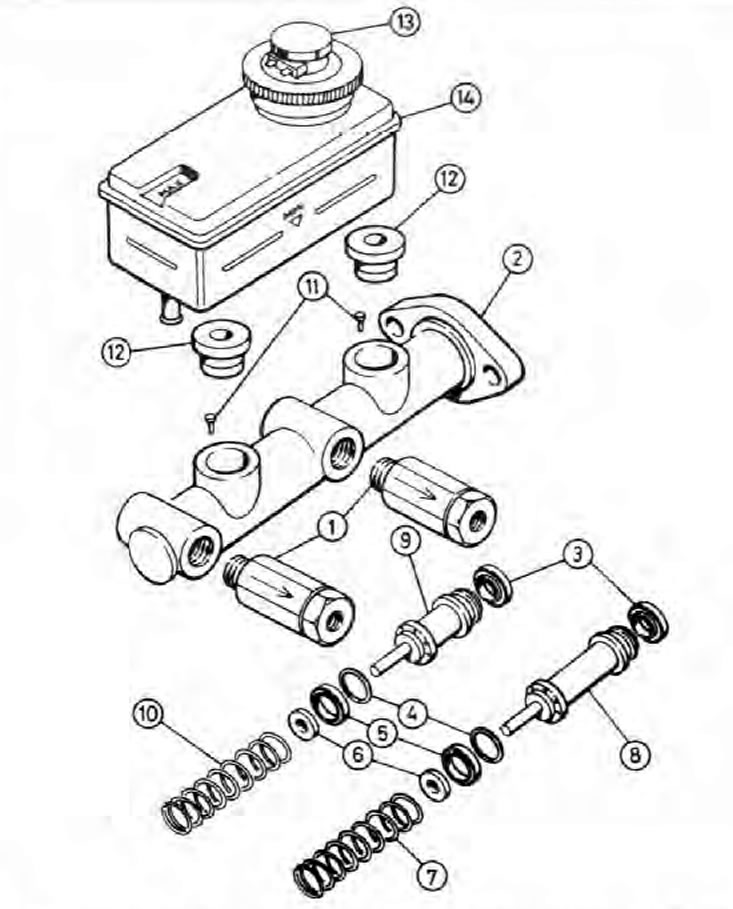

Pic. 9.5. Master cylinder components (early modification)

1. Brake pressure control valves (Hatchback models only. Wagon and Van); 2. Master cylinder; 3. Piston seal; 4. Washer; 5. Piston collar; 6. Spring support; 7. Primary piston spring (wire diameter 1.6 mm); 8. Primary piston; 9. Secondary piston; 10. Secondary piston spring (wire diameter 1.8 mm); 11. Locking pin; 12. Seal; 13. Filler cap and liquid level sensor; 14. Nutrient tank.

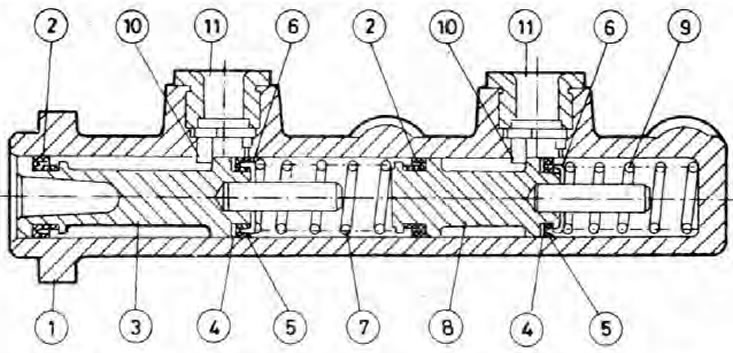

Pic. 9.6. master cylinder (early modification) cutaway

1. Master cylinder; 2. Piston seal; 3. Primary piston; 4. Washer; 5. Piston collar; 6. Spring support; 7. Primary piston spring (wire diameter 1.6 mm); 8. Secondary piston; 9. Secondary piston spring (wire diameter 1.8 mm); 10. Locking pin; 11. Seal.

Note: Please refer to the note given at the beginning of the Chapter 9.

Removing

1. Remove the cover of the master cylinder supply reservoir, disconnect the electrical wiring connector from the brake fluid level sensor and pump out the fluid from the reservoir. Alternatively, open any convenient bleeder valve and gently depress the brake pedal a few times (see chapter 9).

Note: Do not suck out the liquid by mouth as it is poisonous: use a syringe or an old rubber bulb.

2. Unscrew the connecting nuts and separate the metal brake pipes (see chapter 10). Try to keep fluid loss to a minimum and clean up any spilled fluid as soon as possible.

3. Unscrew the two nuts securing the master cylinder to the vacuum booster block and remove the cylinder (see photo).

Bulkhead

Note: Before proceeding with a cylinder overhaul, check the availability of the required repair kit of parts and other necessary components and their prices, compare them with the price of a new or already remanufactured master cylinder in the workshop, and only then make a decision on the advisability of overhauling. In addition, read the description of the procedure to the end and prepare all the required tools and fixtures.

All models

4. Remove the master cylinder from the engine compartment and clean it thoroughly. Unscrew the pressure control valves in the brake system, where there are (see chapter 12).

5. Press the reservoir away from the master cylinder and remove its two seals from the bores in the cylinder body.

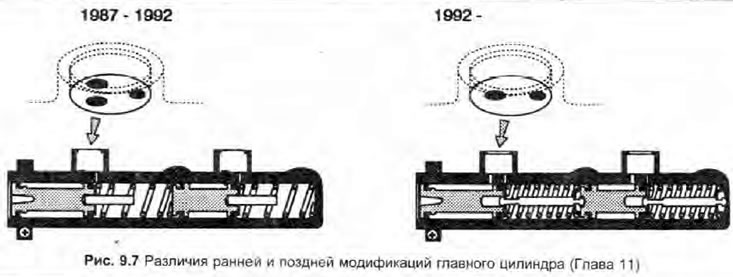

6. Bulkhead procedure for a modified version of the master cylinder. presented on models manufactured since 1992 is slightly different from this point onwards. Identify the cylinder to be removed using fig. 9.7 and proceed as described in the relevant subchapter.

Models produced from 1987 to 1992

7. Push the primary piston into the cylinder as far as possible and remove the piston locking pins from the reservoir inlets by turning the assembly upside down and tapping it on a clean surface.

8. Noting the removal order and orientation of each component, remove the piston assemblies with their springs and seals. To remove the assemblies from the cylinder, tap it against a clean wooden surface. If necessary, clamp the master cylinder in a soft-toothed vise and blow low pressure compressed air through the secondary circuit port to facilitate removal of the secondary piston assembly.

Warning: Be careful, the piston may jump out of the cylinder with some acceleration.

9. Thoroughly clean all components using only methyl or isopropyl alcohol, or clean brake fluid. Never use mineral solvents such as gasoline or kerosene for this purpose - they will damage the rubber components of the brake hydraulic system. Dry the components using compressed air or a clean, dense (lint-free) textile.

10. Inspect all components and replace any that are worn or damaged. Pay special attention to the inner walls of the cylinder and the pistons - the complete cylinder assembly should be replaced if they are scratched. worn or corroded. If there is any doubt about the condition of the assembly or any of its components, perform the appropriate replacement (see note given in Chapter 1). Make sure cylinder inlets and bypasses are not clogged.

11. If the assembly is usable, purchase the components needed to assemble it. Be sure to replace all seals and rubber support cups - they should never be reused.

12. At assembly impregnate pistons and new basic cups and consolidations by a pure brake liquid. Apply clean fluid to the walls of the cylinder bore.

13. Install new components in the grooves of the respective pistons without using any tools.

14. Insert the pistons into the cylinder using a rotary motion so that the sealing lips do not get stuck. Make sure all components are installed in the correct order and properly oriented.

15. Push the secondary piston assembly completely into the caliper barrel using a clean metal rod, then install the locking pin.

16. Install the primary piston assembly and its locking pin.

17. Insert new seals into the cylinder bores, then install the reservoir and, where necessary, brake pressure control valves.

18. Install the master cylinder in the engine compartment.

Models since 1992

19. Lightly tap the cylinder on a clean wooden surface to release the piston assemblies, along with their springs and seals, from the cylinder. Note the removal order and orientation of each component. Piston assemblies are held on these models only by the vacuum booster assembly; if they cannot be removed, use low pressure compressed air (see point 8 above).

20. Disassemble, clean, inspect and prepare components for reassembly as described in steps 9-13 above.

21. Install the springs on the appropriate pushers and attach them, fixing their supports in the working position. Insert the spring and piston assemblies into the cylinder, making sure that all components are installed in the correct order and correctly oriented. Use a twisting motion to do this so that the sealing lips do not get stuck.

22. Insert new seals into the bores of the cylinder, then install the reservoir and, where necessary, the brake pressure control valves.

23. Install the master cylinder in the engine compartment.

Installation

24. Install in the reverse order of removal, paying attention to the following:

- a) Install the master cylinder on the vacuum booster block, aligning the primary piston rod located in the booster with the piston itself in the master cylinder.

- b) Tighten the master cylinder mounting nuts to the specified torque specifications.

- c) Fill the master cylinder reservoir with new fluid and bleed the system (see chapter 9). Check system joints for tightness.

- d) If a new master cylinder has been installed (or the liquid was completely drained from the old), bleed the cylinder, separating the metal tubes from it one by one (front first) and gently depressing the brake pedal until the brake fluid flowing out of the cylinder is free of air bubbles. Place a rag under the flowing stream to collect the liquid.

- e) In particularly difficult cases, disconnect the pipes, plug the openings with your fingers, then open each one in turn when the brake pedal is depressed, and plug again when the pedal is released, thus forcing fluid from the reservoir into the cylinder. Once the master cylinder is free of air. Install and tighten all couplers securely, then proceed with normal bleeding procedure.