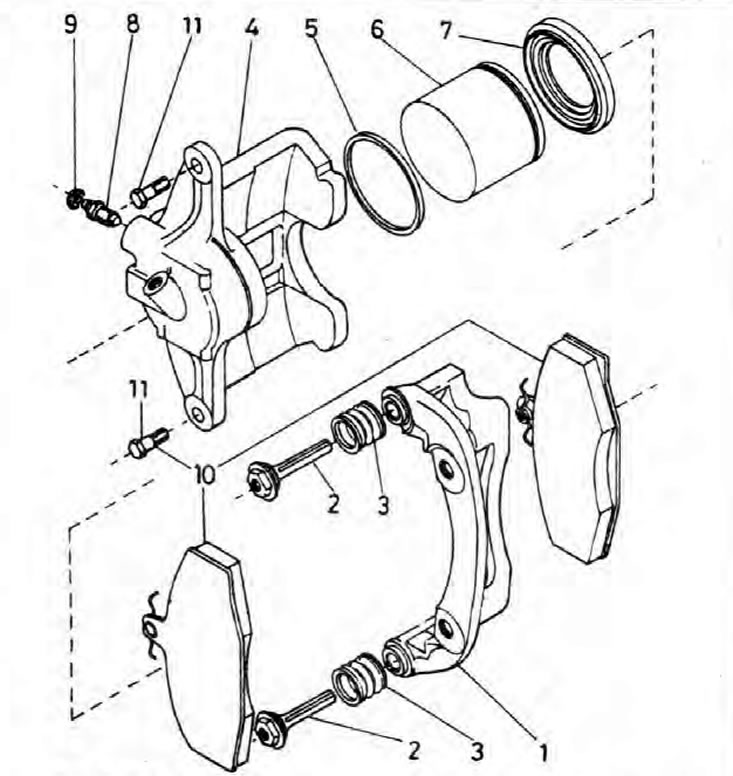

Pic. 9.10. Front brake caliper components

1. Mounting bracket; 2. Guide pin; 3. Rubber dustproof cuff; 4. Caliper; 5. Piston seal; 6. Piston; 7. Dust-proof cuff of the piston; 8. bleed valve; 9. Dust cap; 10. Brake shoe; 11. Guide pin bolt.

Warning: Brake pad sets on coaxial wheels should be changed at the same time - never change pads on one wheel only as this will result in unequal braking. Please note that the dust generated during pad wear may contain asbestos, which is harmful to health. Never blow off dust with compressed air or inhale it DO NOT use gasoline-based solvents to clean brake components. Use only special cleaner or methyl alcohol.

1. Jack up the front of the vehicle and place it securely on axle stands, then remove the wheel.

2. If the check described in Section 1, has shown that the condition of the brake pads is unsatisfactory, remove them and check more carefully as follows.

3. Slide the caliper outward to retract the piston all the way into the cylinder, then make sure the caliper slides into the mounting bracket without jerking. If this is not the case, the drive pins should be cleaned, checked for signs of wear, and lubricated prior to assembly.

4. Loosen the lower caliper drive pin bolt, using a thin double end wrench, if necessary, to lock the head of the caliper drive pin itself (see photo). Turn the caliper up to access the brake pads. Do not press the brake pedal until the caliper is in the working position.

5. Noting the exact location of the compression spring on each brake pad, remove the pads (see photo). Label them like this. so that later each can be installed in its original place. Don't try to swap pads to compensate for uneven wear - this will result in uneven braking.

6. First measure the thickness of the brake lining remaining on each of the brake pads (see photo). Please note that on original Skoda brake pads, the central groove of the pad serves as an indicator of its wear limit: if the brake pad of the pad is worn so that the groove is erased at any point, both pads must be replaced.

7. If any of the pads are worn at any point up to that specified in Specifications minimum thickness. all four front brake pads must be replaced (see warning above). In addition, the pads should be replaced if at least one of them is contaminated with oil or grease; because it is impossible to clean them from the lining.

8. If any of the brake pads show signs of uneven wear or are contaminated with oil or grease, locate and correct the cause before reassembling.

9. If the brake pads are still serviceable, carefully clean them with a clean, soft wire brush or similar tool, paying particular attention to the sides and back of the metal backing. Clean the groove in the brake pad and remove any large debris from the friction material. Carefully clean the brake shoe pressure springs and the inside surfaces of the caliper and mounting bracket.

10. If there is any doubt about the sliding of the caliper in the mounting bracket, disassemble it and then clean and lubricate the guide pins as described in Chapter 15 (see photo). Check the condition of the brake disc (see chapter 16).

11. When assembling, apply some high temperature brake grease or anti-lock compound (For example. Holts Copaslip) on the side sections and the back of the metal base of each pad and those surfaces of the caliper and mounting bracket that come into contact with the pads. Do not allow grease to get on the brake pads.

12. Install brake pads with friction linings facing the disc.

13. If new pads are installed. push the caliper piston all the way into the cylinder to make enough room for them. Use either a clamp or similar tool, or suitable wooden blocks for this (as leverage). Provided that the reservoir of the master cylinder is not overfilled with brake fluid, it should not overflow, however, just in case, watch the fluid level while you sink the piston. If the liquid level rises above the line «max», pump out the excess or drain it through a plastic tube mounted on the bleeder (see paragraph 1 of Chapter 11).

14. Move the caliper down onto the brake pads and install the lower guide pin bolt. Skoda recommends replacing these bolts after each removal as they are coated with a blocking compound which loses its effectiveness. For this reason, Skoda branded brake pad sets are equipped with new bolts. If new bolts are not available, carefully clean the threads of the bolt with a wire brush and apply one or two drops of a special blocking compound to the bolt before installation. Tighten the bolt with a torque specified specifications.

15. Make sure that the caliper slides smoothly in the mounting bracket, then press the brake pedal several times so that the pads are firmly pressed against the brake disc and normal pedal travel is restored. Install the wheel.

16. Repeat this procedure on the opposite brake caliper, then lower the vehicle to the ground and tighten the wheel bolts to the specified torque specifications (see Section 1 Specifications).

17. Check the brake fluid level (see section 1).

18. Keep in mind that new pads need to be worn in, so the car will have to travel several hundred kilometers before maximum braking performance is achieved. As far as possible, avoid hard braking during this period and be prepared for longer braking distances.