Warning: Brake pad sets on coaxial wheels should be changed at the same time - never change pads on just one wheel. because this will result in uneven braking. Please note that the dust generated during pad wear may contain asbestos, which is harmful to health. Never blow off dust with compressed air and try not to inhale it. DO NOT use gasoline-based solvents to clean brake components. Use only special cleaner or methyl alcohol.

Inspection

1. Remove and inspect the brake drum (see chapter 20).

2. Gently (see warning above) remove from the brake drum. its support shield and pads all traces of dust formed as a result of pad wear. Make sure the brake pads are not contaminated with oil or grease, which can be the result of careless maintenance. To protect the brake pad lining from such contamination, you can use adhesive tape or something similar. provided that its adhesive layer does not itself contaminate the material. Do not forget to remove the tape from the shoes afterward before installing the drum.

3. Measure the thickness of the brake pads in several places (see photo). If at least one of the pads in any place is worn to the specified in Specifications minimum thickness, all four pads must be replaced (see warning above). The pads should also be replaced if any of them are contaminated with oil or grease. There is no effective way to degrease brake pads.

4. If one of the brake pads is worn unevenly or contaminated with oil or grease, locate and correct the cause before reassembly.

5. Gently prying up each of the rubber protective caps, check the working brake cylinders for leaks and signs of corrosion and ensure that the plungers and pistons move freely (see chapter 22).

6. Apply a small amount of brake lubricant (see paragraph 17) on the pivot points and running surfaces of the self-adjusting lash adjuster/handbrake mechanism, then verify that the compensator/mechanism is working properly.

7. Install the brake drum (see chapter 20).

8. Repeat the procedure on the opposite brake.

Replacement

Note: The leading brake pad of each rear brake assembly is the pad that is closer to the rear of the car in relation to the working brake cylinder - these pads are different from each other and must be installed strictly on the brake assembly for which they are intended. The second pad of each assembly is driven, these pads of the left and right rear brakes are the same.

9. Remove and inspect the brake drum (see chapter 20).

10. Gently (see warning above) remove all traces of dust from the brake drum, its support plate and pads as a result of worn brake linings. Press the toothed segment of the self-adjusting lash adjuster to move the pads away from the drum.

11. Unhook the handbrake cable (compressing his spring) from the operating lever on the driven brake shoe.

12. Using pointed pliers or a similar tool, unhook the lower shoe return spring.

13. Remove the shoe support posts by pressing on their free ends to release.

14. Unhook as necessary components of the self-adjusting gap compensator / hand brake mechanism and remove the brake pads. Do not depress the brake pedal until the brake assemblies are assembled. Put a tight rubber band or something similar on the working brake cylinder to fix the plungers and pistons in it (see photo).

|  |

15. Place the assembly on a clean work surface and unhook the top shoe return spring. Separate the brake pads and disassemble the self-adjusting lash adjuster/handbrake mechanism by removing the appropriate spring and locking calipers. Clean all components, inspect them for signs of wear and damage, and replace any that are no longer fit for use.

16. Bend back the rubber protective covers, check the working brake cylinder for damage and tightness and make sure that the plungers and pistons move freely in it (see chapter 22).

17. Clean the drum brake support shield and apply some high temperature brake grease or anti-lock compound (e.g. Holts Copaslip) on all working surfaces and hinged parts, as well as on areas and components in contact with the pads, especially on the plungers of the working brake cylinder and the lower guide of the brake pads. Do not let grease vane onto the brake pads. To protect the brake lining from such contamination, adhesive tape or something similar can be used, provided that its adhesive layer does not itself contaminate the material. Do not forget to remove the tape from the shoes afterward before installing the drum.

18. When installing, assemble pads and self-adjusting lash adjuster/handbrake mechanism on a clean work surface (see photo). Note that the upper shoe return spring must be attached with the shorter hook end to the drive shoe.

|  |

|

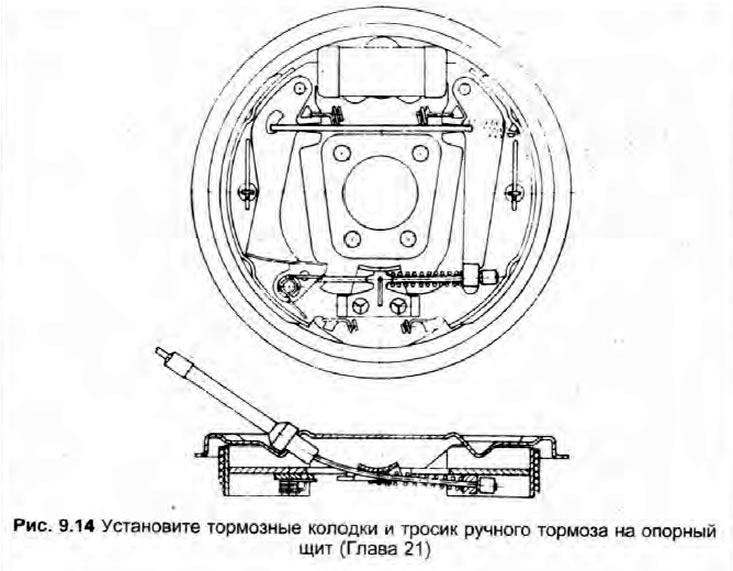

19. Install the assembly on the drum brake support shield, being careful not to allow grease to get on the brake linings. Make sure the shoes are seated properly in the slave cylinder plungers as well as the bottom rail, then install the shoe support posts and spring calipers (see photo). Tap the shoes to center them on the drum brake support plate.

|  |

20. Compress the return spring and connect the handbrake cable to its working lever, making sure that the cable passes through the guide located in the brake support shield.

21. Attach the lower shoe return spring. Make sure all components are properly installed and securely fastened (see photo).

22. Remove adhesive tape (if used) with the brake shoes and rubber band with the working brake cylinder, then install the brake drum (see chapter 20).

23. Repeat the procedure on the opposite brake.

24. Keep in mind that new pads need to be worn in, so before maximum braking performance is achieved, the car must travel several hundred kilometers. As far as possible, avoid hard braking during this period and be prepared for longer braking distances.