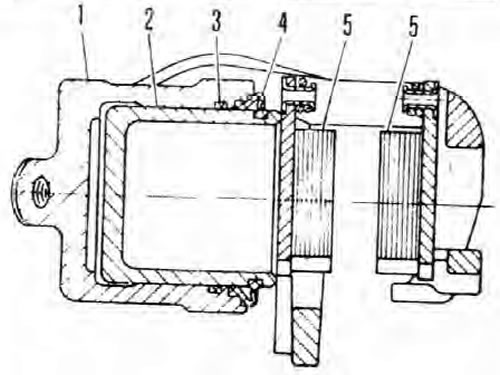

Pic. 9.11. Sectional front brake caliper

1. Caliper; 2. Piston; 3. Piston seal; 4. Dust-proof cuff of the piston; 5. Brake pads.

Note: Please refer to the note given at the beginning of the Chapter 9 and the warning given at the beginning Chapter 13 (regarding asbestos dust).

1. Prepare to remove the caliper as described in paragraphs 1-3 of the previous Chapter.

2. Loosen the caliper drive pin bolts, using a thin double end wrench, if necessary, to lock the pin heads themselves. Remove the caliper by unscrewing it from the hose connector. If a sealing washer is used at this joint, discard it - such washers must be replaced after each removal. Plug the hose connector (or wrap it tightly with polyethylene).

3. Remove and check the condition of the brake pads (see Chapter 13).

4. Remove the drive pins. If necessary, screw their mounting bolts into them and pull the bolt head using a self-locking wrench or similar tool. Remove the rubber dust cover from each of the drive pins and inspect it for cracks or other damage; covers can be replaced separately. If you want to.

5. Unfasten the caliper bracket from the steering knuckle.

6. Place a small piece of wood into the caliper and remove the piston by blowing low pressure compressed air (e.g. with a wheel inflation pump) into the caliper inlet.

Warning: Be careful, the piston may pop out of the caliper with some acceleration.

7. Remove the dust collar and use a blunt knitting needle tool to pry the seal out of the caliper bore.

8. Thoroughly clean all components using only methyl or isopropyl alcohol, or clean brake fluid. Never use mineral solvents such as gasoline or kerosene for this purpose - they will damage the rubber components of the brake hydraulic system. Dry the components using compressed air or a clean, dense (lint-free) textile. Blow out the channels with compressed air.

9. Inspect all components and replace any that are worn or damaged Pay special attention to the inner walls of the caliper bore and piston - the caliper should be replaced if they are scratched, worn or corroded. Also check the condition of the guide pins and their holes in the mounting bracket; both guide pins must not be damaged and (when cleared) quite tight but smoothly to slide in the mounting bracket. If there is any doubt about the condition of any of the components, replace accordingly.

10. If the caliper is suitable for further use, purchase the components necessary to assemble it. Be sure to replace all rubber seals, dust seals and covers, and any sealing washers found during reassembly - these should not be reused.

11. Before assembly, make sure that all components are absolutely clean and dry.

12. Soak the piston and its new seal with clean brake fluid (within an hour before assembly). Lubricate the bore of the caliper cylinder with clean fluid and install a new seal in its inner groove without using any tools.

13. Install a new dust seal on the inner end of the piston, then place its outer edge into the outer groove of the caliper cylinder. Push the piston into the caliper using a twisting motion and being careful not to warp the piston. When the base of the piston sinks into the caliper, install the inner edge of the dust seal into the piston groove.

14. Uncork the hose opening and screw the caliper onto its connector, firmly clamping it by hand. If a sealing washer was found during reassembly, be sure to replace it.

15. Install the caliper mounting bracket on the steering knuckle and tighten its two mounting bolts with a torque specified specifications.

16. Install a new rubber dust cover on each of the drive pins and apply a little grease to the pins before installation; Any quality high temperature brake grease or anti-lock compound can be used (e.g. Holts Copaslip).

17. Install the brake pads (see Chapter 13).

18. Install the caliper into the mounting bracket over the brake pads, then screw in the guide pin bolts. Skoda recommends that these bolts be replaced each time they are removed, as they are coated with a blocking compound that loses its effectiveness. For this reason, Skoda branded brake pad sets are equipped with new bolts. If new bolts are not available, carefully clean the threads of the bolt with a wire brush and apply one or two drops of a special blocking compound to it before installation. Tighten the bolt with a torque specified specifications.

19. Make sure the caliper slides smoothly into the mounting bracket.

20. Make sure the hose is routed correctly, not kinked, and clipped, and tighten the coupling securely.

21. Bleed the system (see chapter 9), then depress the brake pedal several times until the pads are pressed firmly against the brake disc and normal pedal travel is restored.

22. Wash off the spilled liquid from the adjacent components and check the system joints for leaks, asking the assistant to depress the brake pedal to the stop. Install the wheel.

23. Repeat this procedure on the opposite brake caliper, then lower the vehicle to the ground and tighten the wheel bolts to the specified torque specifications.

24. Check the brake fluid level (see section 1). Inspect the joints of the system for smudges.