General description

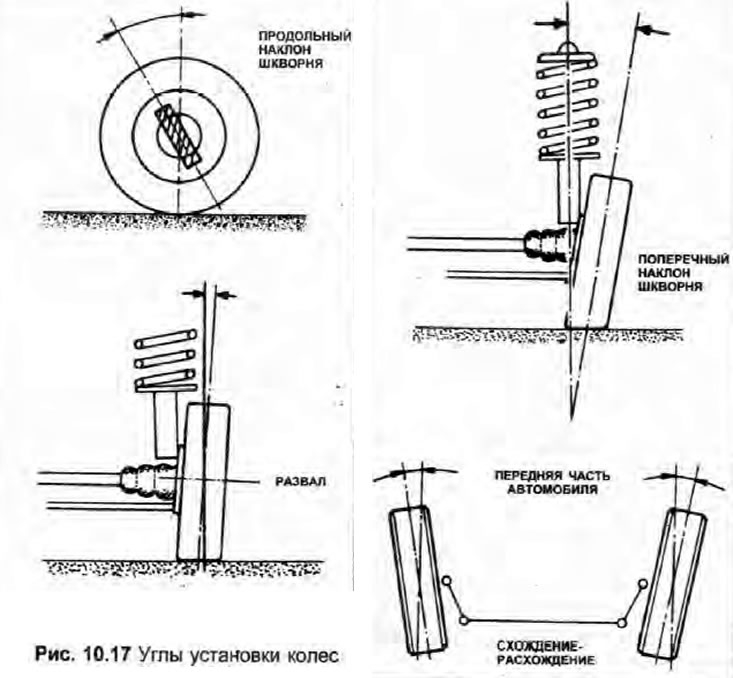

1. The geometry of the steering gear and suspension of the car is determined by five main parameters, all angles are expressed in degrees, the axis of the kingpin is defined as an imaginary line drawn through the centers of the upper mount of the front suspension strut and the ball joint of the lower arm to the ground.

2. Camber - the angle at which the wheels are turned relative to an imaginary vertical drawn between the front or rear wheels. Positive camber - angle (expressed in degrees), by which the upper part of the wheels is deflected from the vertical.

3. Camber is not adjustable and is for information only; but it can be checked with a special pattern. If the camber value is significantly different from that specified by the manufacturer, contact a professional for an accurate check, the malfunction can only be caused by wear or damage to the suspension or body components.

4. Kingpin pitch - the angle between the axis of the kingpin and a vertical line drawn through the center of the wheel, as viewed from the side of the vehicle. Positive kingpin caster - when the kingpin axle is tilted so that the wheel touches the ground in front of the vertical; negative pitch of the kingpin - when the wheel touches the ground beyond the vertical.

5. Kingpin pitch is not adjustable and is given for information only; but it can be checked with a special pattern. If the value differs from that specified by the manufacturer, contact a professional for an accurate check, the malfunction can only be caused by wear or damage to the suspension or body components.

6. The transverse inclination of the kingpin - the angle formed by the vertical and an imaginary line drawn through the upper and lower mounts of the front suspension strut.

7. Kingpin lateral tilt is not adjustable and is given for information only.

8. Convergence - the amount by which the distance between the inner edges of the front wheel rims differs from the distance between the inner edges of the rear wheel rims. If the distance between the front edges is less, then they talk about the convergence of the wheels, and if more - about their divergence.

9. To adjust the toe of the front wheels, the tie rods are screwed into or unscrewed from the ball joints, thereby changing the overall length of the link assemblies.

10. Rear wheel alignment is not adjustable and is given for information only; this value can be checked as described below, and if the result is significantly different from that specified by the manufacturer, contact a professional for an accurate check, the malfunction can only be caused by wear or damage to the suspension or body components.

11. Reverse toe-in is the difference between the steering angles of the inner and outer front wheels when they have been turned through a certain angle.

12. Reverse toe-in is set during vehicle manufacture and cannot be adjusted except by unevenly changing the length of the tie rods. Therefore, it is essential to check the equality of the length of the steering rods after adjusting the convergence.

Verification - general description

13. Since the measurement requires precise instruments, it is recommended to entrust the check to a Skoda dealer or a specialist who has the necessary equipment.

14. For an accurate measurement, the car must be with a normal net weight (not loaded). Before starting work, check that the tire sizes and types match, then check the tire pressure and tread wear, the condition of the hub bearings, the steering wheel play and the condition of the front suspension components (Section 1). Eliminate the found faults.

15. Park your car on level ground (not slanted). Make sure the front wheels are in the straight ahead position, then rock the front and rear of the car to get the suspension components properly in place. Release the handbrake and roll the vehicle back about 1 meter, then forward again to relieve stress on the steering and suspension components.

Reverse toe-in in corners - check and adjustment

16. Toe-in can be checked using only a couple of special templates.

17. Prepare the car as described in points 14 and 15 above. Roll the car back and make sure the front wheels are in the straight ahead position, then roll the car forward on the special templates so that the front wheels are in the center of the plates.

18. Turn the steering wheel first in one direction until the outer wheel turns to the direction indicated in Specifications corner; record the angle of rotation of the inner wheel. Then turn the steering wheel back through the straight ahead position and repeat the test on the other side.

19. If it turns out that the inner wheel is not turned to the specified Specifications angle, make sure both tie rods are the same length. If the length is different. correct it, but this will affect the convergence (see below) and steering wheel position.

20. If the angles are not correct, but the tie rods are the same length and the steering components are in good condition, the front suspension components or body are damaged. For a thorough check, contact a Skoda dealer or specialist as soon as possible.

Convergence - check and adjustment

21. The procedure below applies to the front wheels only. As noted in point 10 above, although the rear toe can be checked, it cannot be adjusted and any change will be caused by wear or damage to the suspension or bodywork.

22 Toe-in can only be checked with a special gauge, by measuring the distance between the inner edges of the wheels front and rear. Obtain a toe gauge, or make one from a piece of steel tubing, bending it to bypass the clutch housing and suspension, and attaching a set screw and locknut to the end.

23. Prepare the car as described in points 14 and 15 above.

24. First measure the distance between the inner edges of the front wheel rims at the height of the center of the hub at the rear; name this value «A».

25. Roll the car forward so that the wheels turn exactly 180° (half turn) and again measure the distance, but now at the height of the center of the hub in the front; name this value «IN».

26. To ensure maximum accuracy, repeat the measurements three times at points on the wheel rims separated by 120°and calculate the average.

27. To determine convergence, subtract «IN» from «A»; The result must be within the limits specified in Specifications allowable deviations.

28. If adjustment is necessary, jack up the front of the vehicle and place it securely on axle stands. Clean the tie rod threads first. Loosen the outer brackets of the rubber boot guards, lift the boots slightly and grease their edges so that they move freely and do not deform when the tie rods rotate.

29. With the edge of the ruler and a marking tool, mark the position of the rods relative to the ball joints, then while holding the ball joint, loosen the lock nuts.

30. Change the length of both tie rods (by the same amount), screwing them into the ball joints or vice versa unscrewing a quarter of a turn and checking the convergence until you get the correct value; shortening the tie rods (screwing into ball joints) will lead to a decrease in convergence and an increase in divergence when cornering. If the tie rods have nothing to turn with a wrench (see photo), twist them with the self-locking key.

31. To keep the length of the tie rods equal, always turn them in the same direction (when viewed from the center of the car).

32. When the toe is properly adjusted, hold the ball joints and tighten the locknuts securely. Make sure the ball joints are properly seated in their sockets and count the number of threads on the protrusions to check the length of both tie rods. If the length is not the same, then the adjustment is not correct and the tires will wear out when cornering; and the steering wheel will not be in the straight ahead position.

33. If the length of the steering rods is the same, lower the car to the ground and prepare it (paragraphs 14 and 15 above), and then check the convergence (paragraphs 24-27); repeat the adjustment if necessary. If the toe-in is correct, check that the rubber boots are correctly placed and not distorted, then secure them with staples.