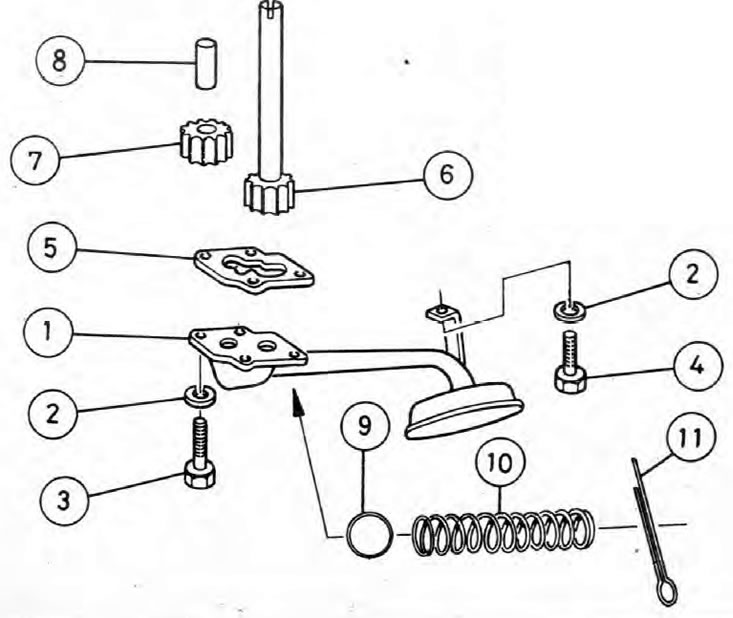

Pic. 2A.6. Oil pump components

1. Suction tube / oil pump strainer; 2. Spring washer; 3. Bolt - receiving tube to the drive cover; 4. Bolt - suction tube/strainer to bearing cap; 5. Gasket (where available); 6. Oil pump drive gear; 7. Oil pump driven gear; 8. Oil pump driven gear shaft; 9. Ball reducing oil valve; 10. Spring reducing oil valve; 11. Hairpin.

Removing

1. Remove the pallet as described in Chapter 10.

2. Remove the four bolts securing the oil pump pickup tube to the back of the drive cover and one bolt securing it to the center main bearing cap. Carefully separate the pickup tube/strainer from the drive cover. Be careful, the oil pump gears will fall out once the cover is removed (see illustrations). Remove gasket (where available) - it needs to be replaced.

|  |

|

Inspection

3. Inspect the gears and oil pump housing for gouges or damage. If the necessary gauges are available, wear on the shafts and pump housing can be determined. If the amount of wear exceeds the allowable Specifications values, pump gears and main drive chain cover (which includes the oil pump housing) must be replaced as a set. For information on removing and installing the timing chain cover, see Chapter 7.

4. Temporarily insert the gears into the pump housing, and using the edge-mounted ruler and feeler gauges, measure the clearance (axial play) between gear and cover (see illustration). Skoda states that the gap between the gears and the cover should be no more than 0.1 mm. If the gap is approximately 0.1 mm, then the pickup tube/strainer must be installed without a gasket. If the gap is very small or there is none at all, then install a gasket of suitable thickness behind the cover. If the clearance is greater than 0.1 mm, the pump housing and/or gears are worn and the oil pump assembly must be replaced.

5. Remove pin from oil pump suction tube/strainer, and remove relief valve spring and ball (see illustrations). Inspect them for damage and signs of wear and replace as needed. If a new ball is installed, insert it into the receiving tube, then use a hammer and a suitable soft metal drift to hammer into place; this will ensure the correct functioning of the valve. Finally, secure the ball and spring with a new pin.

|  |

Installation

6. Where necessary, place a new gasket on the mating surface of the oil pickup tube assembly.

7. Lubricate the gears and oil pump shafts liberally, then insert the gears into the housing. Install the oil pump suction pipe/strainer, and insert the five mounting bolts. Tighten the fastening bolts with a torque specified specifications.

8. Install the drip tray as described in Chapter 10.