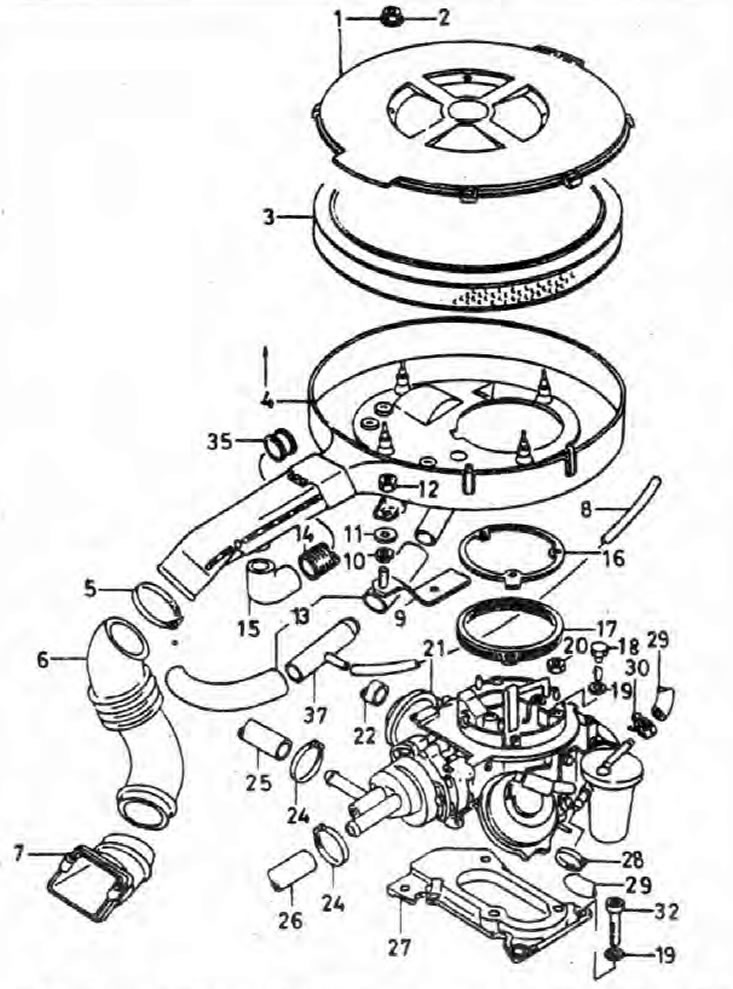

Pic. 4.5. Carburetor, air filter and related components

1. Air filter cover; 2. Nut; 3. Filter element; 4. Air filter body; 5. Bracket; 6.Inlet hose; 7. Adapter; 8. Ventilation hose; 9. Bracket; 10. Rubber bushing; 11. Washer; 12. Nut; 13. Ventilation hose; 14. Hot air hose; 15. Elbow; 16. Mounting plate; 17. Gasket; 18. Screw; 19. Washer; 20. Nut; 21. Carburetor; 22. Hose; 24. Bracket; 25. Cooling system outlet pipe; 26. Inlet hose of the cooling system; 27. Mounting flange and gaskets; 28. Bracket; 29. Fuel hose; 30. Staple; 32. Screw; 35. Tip; 37. T-connection.

1. Carburetor Pierburg 2EZ (Jikov 28-30 LEKR) - two-chamber with a falling flow and a vacuum secondary throttle valve (see illustration).

2. An air-fuel mixture is formed in the carburetor that corresponds to the operating conditions. This is achieved in the following way.

3. Fuel enters the carburetor through the filter and is collected in the float chamber. The fuel level in the chamber is controlled by a float and a needle installed in the fuel inlet. When the fuel level in the chamber drops, the float drops and the needle opens the valve. When the fuel reaches the correct level, the regulator closes and the fuel supply stops. An air passage between the float chamber and the air filter prevents the possibility of pressurization in the chamber, and also reduces the effect of a clogged air filter on the air/fuel mixture.

4. Adopt semi-automatic cold start system (damper). When the engine is cold, the choke is actuated by a single (or double in frosty weather) pressing the gas pedal. This actuates the fast idle cam; the bimetal spring closes the automatic choke and the fast idle cam moves to the fast idle position. When the gas pedal is released, the throttle will move to the cold start position and the fast idle adjustment screw will rest against the highest notch on the fast idle cam.

5. When the ignition is turned on, the idle mixture shut-off valve opens, fuel is supplied to the carburetor, and the bimetal spring in the throttle cover is activated. As the engine cranks, vacuum builds up on the choke side and fuel begins to be sucked out of the primary choke system. Over-enrichment of the mixture is prevented by the fact that the air damper is installed slightly offset so that it is slightly open and a small amount of air always passes by.

6. At the moment the engine is started, the vacuum in the diffuser drives the exhaust diaphragm, which opens the air damper, and additional air enters the system, preventing excessive enrichment of the mixture. Diaphragm rod movement is limited by a locking screw. Air flows into the block «pull-down» through a thermal valve with a timer, reducing the effectiveness of the vacuum pull diaphragm in the cold state. When the thermal valve closes, the efficiency of the exhaust diaphragm increases and the air damper opens further.

7. As the engine warms up, any movement of the gas pedal acts on the lever, turning the fast idle cam. By reinstalling the fast idle adjuster screw on the warm-up part of the cam, decreasing the throttle opening accordingly.

8. As the engine temperature rises to normal operating temperature, the bimetal spring and lever gradually open the choke, leaning the mixture. The fast idle screw moves to the extreme step of the warm-up stage on the fast idle cam. At normal operating temperature, the screw does not touch the cam and the idle speed is determined only by the throttle position and the amount of mixture passing through the idle bypass circuit.

9. To prevent excessive richness of the mixture during acceleration during the warm-up stage, the primary throttle and choke are mechanically linked, and the choke always moves to the middle of the setting range.

10. To prevent fuel flooding when the throttle is fully opened while the engine is not yet warm, a special mechanism is activated by which the cam on the throttle lever rotates the throttle lever counterclockwise, partially opening the throttle.

11. The accelerator pump only works when the throttle is less than half open. The pump is mechanically actuated by a lever and cam attached to the primary throttle linkage. Less fuel enters the primary diffuser, and its excess returns to the float chamber through a calibrated channel.

12. The calibrated main jet regulates the amount of fuel supplied from the float chamber to the main air stream. A combined emulsion tube is installed at the base of the float chamber; corrective air jet, the mixture of fuel and air passes through the auxiliary diffuser into the main air stream.

13. At idle and light operating conditions, the fuel outlet channel and the enrichment channel are blocked by vacuum pressure acting on the diaphragm. When the throttle valve is open, the vacuum in the manifold is reduced, the diaphragm returns under spring force, the fuel port valve opens and additional fuel begins to flow.

14. When running at low speeds, only the primary diffuser functions. When the speed of the air flow through the primary diffuser reaches a certain level, the vacuum acting on the secondary diaphragm activates the secondary throttle. A special jet prevents the occurrence of frequency fluctuations caused by the beginning of the opening of the secondary throttle. Once the secondary throttle opens, the action of the secondary circuit becomes almost the same as the primary.

15. At full load and maximum engine speed, the airflow velocity creates a vacuum sufficient to suck fuel from the float chamber into the vertical pipe and then through the calibrated bushing to the top of the secondary air intake. From here, the fuel is fed through the maximum load mixture enrichment tube into the air stream.

16. The intake manifold is heated by coolant to improve the gas properties of the air-fuel mixture. For the same purpose, there is an electrical heating device for the throttle body.

17. The steam trap is mounted on a bracket on the side of the carburetor. Its function is to provide a continuous flow of fuel to the float chamber at high temperatures where vapors can cause erratic operation and difficult starting of the engine.

18. The trap is part of a calibrated return fuel system. Fuel that is not required by the carburetor is returned to the tank. Thus, fuel is supplied to the carburetor only when it is relatively cold.