2. When measuring new rings, place all piston/rod sets according to their location in the engine.

3. If the gap of the new ring cut is too large or too small, double check that the rings are of the correct size class. If the gap is still too small, it can be increased with a needle file; and if the gap is too large, then carefully check the dimensions of all components and new parts.

4. After checking the rings can be installed; at the same time, make sure that each ring is installed only in the correct groove of the corresponding piston.

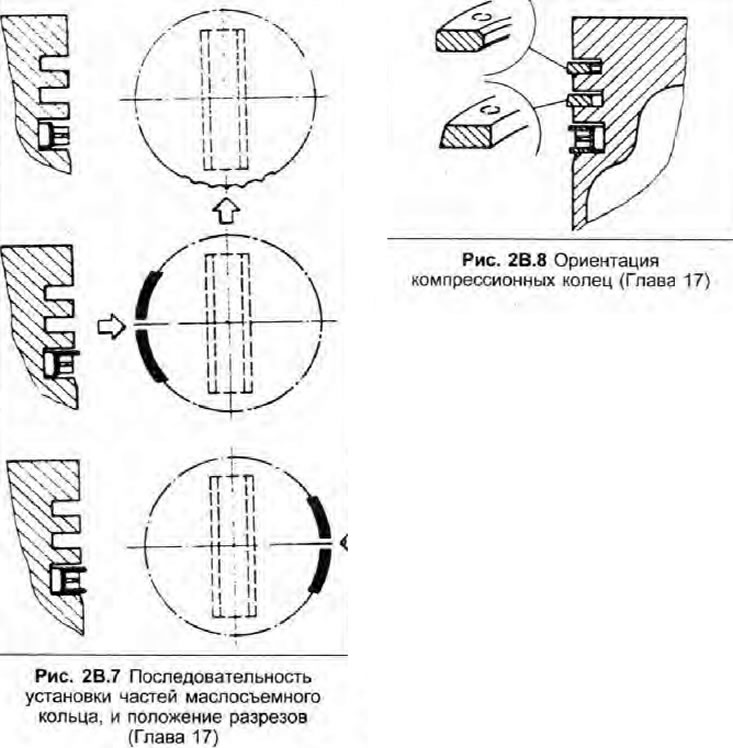

5. Install new rings through the piston head, starting with the oil ring spring. Position the cuts of the spring and oil ring parts as shown in Fig. 2B.7.

6. Install the top and second compression rings behind the oil scraper ring. The second ring can be distinguished from the upper one by the conical outer surface. Note that both compression rings must be installed with the manufacturer's markings facing up (see fig. 2B.8).