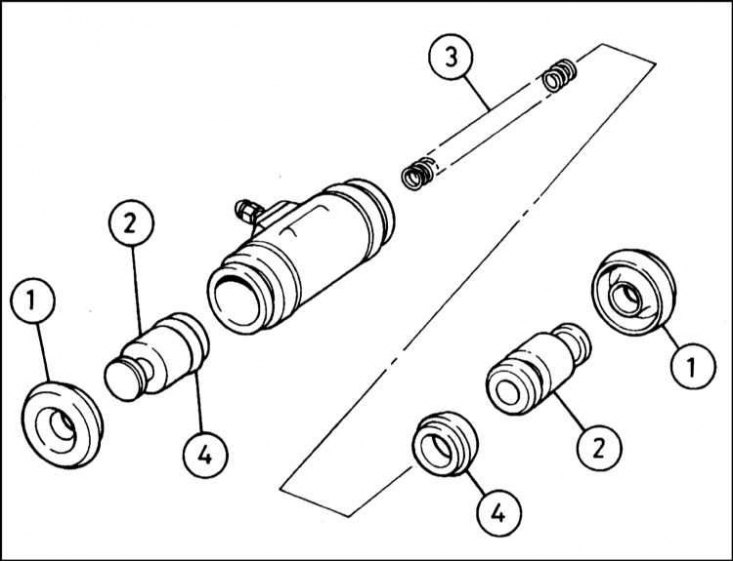

Wheel Cylinder Components

1 - duster; 2 - Piston; 3 - Expanding spring; 4 - Cuff

Attention! Before proceeding with the procedures, carefully read the warning text at the beginning of the Sections System design, description of individual components and mechanisms, Replacing the pads of the disc brake mechanisms of the front wheels, Removal, check of a condition and installation of drums of brake mechanisms of back wheels.

Removing

1. Remove the brake drum (see Section Removal, check of a condition and installation of drums of brake mechanisms of back wheels).

2. In order to minimize the loss of brake fluid, remove the cap from the GTZ reservoir, then, placing a plastic film under it, screw it back onto your neck. In this case, proper sealing of the tank is achieved, which does not allow the liquid level to fall excessively due to the resulting rarefaction. Alternatively, fluid loss can be minimized by pinching the flexible hose of the given brake mechanism with a special clamp or clamp.

3. Carefully disengage the top return spring from both shoes and remove it from the brake mechanism. Spread the upper ends of the shoes apart, disconnecting them from the pistons of the wheel cylinder.

4. Thoroughly wipe the union connection of the brake pipe from the rear side of the wheel cylinder. Give the union nut. Carefully move the tube away from the cylinder and cap the end to prevent dirt from entering the system. Remove any spilled liquid immediately with a rag.

5 Remove the fixing bolts from the rear side of the brake shield and remove the wheel cylinder - try not to splash brake fluid out of it on the friction linings of the shoes.

Overhaul

1. Use a brush to remove traces of dirt and dust from the surface of the wheel cylinder - in order not to inhale the latter, put on a protective mask or respirator.

2. Remove the rubber boots from the ends of the wheel cylinder housing.

3. Pistons are usually squeezed out of the cylinder by the buoyant force of an expanding helical spring. Otherwise, tap the end of the cylinder body with a hammer through a block of wood, or pump low pressure air into the cylinder through the hydraulic fitting (e.g. with a foot pump).

4. Check up a condition of surfaces of pistons and cylinder mirrors. Replace cylinder assembly if scratches, nicks, or metal contact marks are found.

5. If the condition of the pistons and cylinder mirrors is found satisfactory, discard the old cuffs and prepare a repair kit with a full set of necessary components.

6. Remove pistons old cuffs (try to remember their installation position), then moisten the new ones with clean brake fluid and use your fingers to fill them into the cylinder (large diameter forward).

7. Dip the pistons in fresh brake fluid and insert the expansion spring into the cylinder.

8. Rotate the pistons into the cylinder using a rotational motion.

9. Establish anthers and check up freedom of a course of pistons in the cylinder.

Installation

1. Make sure that the mating surfaces of the wheel cylinder and brake shield are clean. Spread the shoes apart and refuel the cylinder in its regular place. Connect the brake pipe to the cylinder and tighten the union nut of the union connection one or two turns. Now screw in the wheel cylinder mounting bolts and tighten them to the required torque.

2. Finally tighten the flare nut and remove the clamp from the flexible brake hose / remove the plastic film from under the cap of the GTZ reservoir.

3. Make sure that the brake shoes are correctly placed in the pistons of the wheel cylinder. Install the top return spring making sure it is properly engaged on the shoes.

4. Install the brake drum (see Section Removal, check of a condition and installation of drums of brake mechanisms of back wheels).

5. Bleed the hydraulic system (see Section Bleeding the hydraulic system).

Note. If proper measures have been taken to minimize the loss of brake fluid, it will be enough to pump only this particular wheel cylinder.