Note. When assembling, you will need new nuts for the axle axle bolts, as well as nuts for the lower suspension strut mounts.

Removing

1. Chock the front wheels, then jack up the rear of the vehicle and place it on jack stands. Disconnect the negative cable from the battery and remove both rear wheels.

2. Acting in accordance with the instructions given in Chapter Brake system, perform the following procedures:

- a) Give the locking and adjusting nuts of the parking brake cables and disconnect the latter from the equalizer plate. Under the car, release the front ends of both cables from the intermediate clips on the bottom of the car so that they can be freely removed together with the rear axle;

- b) Go through the hydraulic pipes from the brake shields to the unions attached to the brackets on the underside of the vehicle just ahead of the rear axle assembly. Thoroughly wipe the connections, then give the union nuts and disconnect the tubes. Release fixing collars and release hoses from brackets. Seal the open ends of the line immediately to minimize brake fluid loss and to prevent dirt from entering the hydraulic system;

- c) On ABS equipped models, run through the wiring harness from the wheel sensors to the connectors. Disconnect both connectors. Release the electrical wiring from the intermediate clamps so that it can be easily removed along with the bridge;

- d) On non-ABS models equipped with a load-sensing control valve, mark the position of the bolt head in the valve spring with respect to the axle. Give a nut, take a bolt and disconnect a spring.

3. Make sure that all interfering components are disconnected, then support the rear axle assembly with a cart jack.

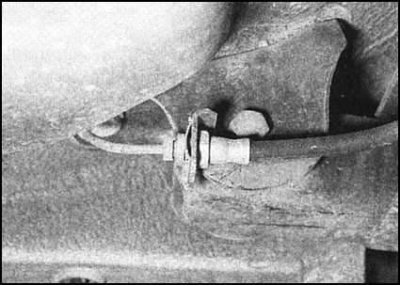

4. Give nuts of bolts of fastening to the bridge of the bottom support of racks of a suspension bracket.

Note. During assembly, the nuts must be replaced without fail.

5. With the help of an assistant, release the nuts of the axle axle bolts and carefully remove the latter from under the car.

Note. The nuts of the axle bolts of the bridge must be replaced without fail.

6. Check up a condition of axial plugs of the bridge. Replace if necessary. The replacement of axle bushings is carried out using a hydraulic press and should be entrusted to car service specialists. If you have the necessary equipment at hand, squeeze out the bushings and press new ones in their place, using a mandrel resting on the outer edge of the bushing.

7. If it is necessary to replace the axle mounting brackets, mark their position on the bottom of the vehicle, then loosen the mounting bolts and remove the brackets. Install new brackets in place of the removed brackets, screw in the mounting bolts, align the brackets in accordance with the marks made during the dismantling process, then tighten the fasteners with the required force.

Note. If the mounting brackets have been replaced, after completing the assembly, it is necessary to check the parallelism of the installation of the bridge (see Section Vehicle wheel alignment - general information).

Installation

1. Get the bridge to its regular place and insert the axle bolts. Screw on new nuts and tighten them until slightly.

2. Insert the bolts of the lower supports of the suspension struts to the bridge. Screw on new nuts, also without tightening them at this stage.

3. In accordance with the instructions given in Chapter Brake system, perform the following procedures:

- a) At the corresponding complete set connect to the bridge a working spring of the valve regulator, sensitive to degree of loading of the car. Check that the washers are installed correctly. Having achieved the alignment of the marks applied during the dismantling process, tighten the fixing nut with the required force;

- b) On ABS equipped models, connect the wiring to the wheel sensors. Follow the correct laying of the wires and the reliability of their fastening in the intermediate clamps;

- c) Secure the brake hoses to your brackets with clamps. Connect the pipes and firmly tighten the union nuts of the union connections;

- d) Make sure both parking brake cables are routed correctly. Connect the cables to the lever. Screw on the adjusting nuts and fix them with locking nuts. Do not reinstall the lever cover/center console yet.

4. Reinstall the rear wheels, lower the vehicle to the ground and tighten the wheel bolts to specification.

5. Shake the vehicle on wheels to shrink the components, then tighten the nuts of the axle bolts of the axle and the suspension strut mounts to the required force.

6. Completely bleed the brake system (see chapter Brake system), on suitably equipped models, check the correct operation of the pressure regulator valve should be entrusted to a car service specialist.